Home > Press > European effort to bring smart textile at industrial manufacturing level

|

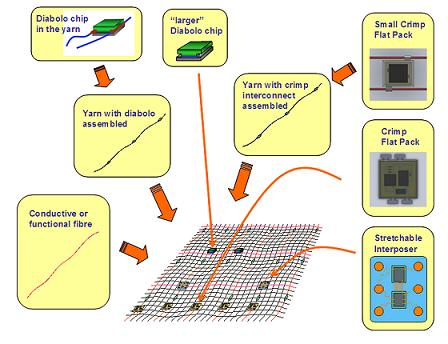

| PASTA Integration concept |

Abstract:

Imec and its project partners announce the launch of the European FP7 (Framework Program) project PASTA (Integrating Platform for Advanced Smart textile Applications) aiming at developing large-area smart textiles.

European effort to bring smart textile at industrial manufacturing level

Leuven, Belgium | Posted on November 3rd, 2010Large-area manufacturability is an essential aspect in bridging the gap between lab prototyping and the industrial manufacturing of smart textiles for sports and leisure wear, technical textiles for safety and monitoring applications, and textiles for healthcare monitoring purposes.

The PASTA project will combine research on electronic packaging and interconnection technology with textile research to realize an innovative approach of smart textile. By introducing new concepts for electronic packaging and module interconnect, a seamless, more comfortable and more robust integration of electronics in textile will be possible. The main technological developments will concentrate on a new concept for bare die integration into a yarn (by means of micromachining), a new interconnect technology based on mechanical crimping, and the development of a stretchable interposer serving as a stress relief interface between the rigid component and the elastic fabric. The technologies will also be assessed in a functional evaluation and reliability testing program. The proposed solutions for integration of electronics in textile will cover a whole range of components, from ultra-small LEDs to complex multichip modules. Moreover, a system design task will tackle the power distribution and system partitioning aspects to provide a complete solution for integration of a distributed sensor/actuator system in fabric.

Four applications areas will be addressed by the project. For outdoor sports and leisure wear, luminous textile with integrated photovoltaic cells will be developed. Moreover, washability will be addressed, as this is an essential aspect of intelligent clothes. PASTA will also explore a bed linen application with an integrated sensor to monitor humidity and signal excessive humidity due to bed-wetting. Two home-textile safety applications will be addressed by integration of building evacuation markings using LEDs. And last, a fabric will be developed which allows non-destructive in-situ monitoring of accumulated stress in composites to predict the residual life-time and to indicate damage of industrial components.

PASTA is a 4-year project, coordinated by imec, and will build on the results of the very successful STELLA project (FP6) and the extensive textile know-how in the consortium. Industrial as well as academic players will bring their expertise to the project: project partners are imec (Belgium), CEA (Commissariat à l'Energie Atomique et aux Energies Alternatives), PEP (Association Pôle Européen de Plasturgie), Sport Soie SAS (France), Fraunhofer IZM, STFI (Sächsisches Textilforschungsinstitut), ETTLIN Spinnerei und Weberei Produktions GmbH & Co KG, Peppermint Holding GmbH (Germany) and CSEM - Centre Suisse d'Electronique et de Microtechnique (Switzerland).

####

About imec

Imec performs world-leading research in nanoelectronics. Imec leverages its scientific knowledge with the innovative power of its global partnerships in ICT, healthcare and energy. Imec delivers industry-relevant technology solutions. In a unique high-tech environment, its international top talent is committed to providing the building blocks for a better life in a sustainable society. Imec is headquartered in Leuven, Belgium, and has offices in Belgium, the Netherlands, Taiwan, US, China and Japan. Its staff of more than 1,750 people includes over 550 industrial residents and guest researchers. In 2009, imec's revenue (P&L) was 275 million euro. Further information on imec can be found at www.imec.be.

Imec is a registered trademark for the activities of IMEC International (a legal entity set up under Belgian law as a "stichting van openbaar nut”), imec Belgium (IMEC vzw supported by the Flemish Government), imec the Netherlands (Stichting IMEC Nederland, part of Holst Centre which is supported by the Dutch Government), imec Taiwan (IMEC Taiwan Co.) and imec China (IMEC Microelectronics (Shangai) Co. Ltd.).

About CEA

CEA is a French research and technology public organisation, with activities in four main areas: energy, information technologies, healthcare technologies and defence and security. Within CEA, the Laboratory for Electronics & Information Technology (CEA-Leti) works with companies in order to increase their competitiveness through technological innovation and transfers. CEA-Leti is focused on micro and nanotechnologies and their applications, from wireless devices and systems, to biology and healthcare or photonics. Nanoelectronics and microsystems (MEMS) are at the core of its activities. As a major player in MINATEC campus, CEA-Leti operates 8,000-m² state-of-the-art clean rooms, on 24/7 mode, on 200mm and 300mm wafer standards. With 1,200 employees, CEA-Leti trains more than 150 Ph.D. students and hosts 200 assignees from partner companies. Strongly committed to the creation of value for the industry, CEA-Leti puts a strong emphasis on intellectual property and owns more than 1,500 patent families. For more information about Leti, please visit www.leti.fr.

About Fraunhofer IZM

Invisible – but indispensable – nowadays nothing works without highly integrated microelectronics and microsystem technology. Reliable and cost effective assembly and interconnection technologies are the foundation of integrating these in products. Fraunhofer IZM, a worldwide leader in the development and reliability analysis of electronic packaging technologies, provides its customers with tailor-made system integration technologies on wafer, chip and board level. Fraunhofer IZM has seen a great deal of success since its founding in 1993 from research groups of the Research Center for Microperipheric Technologies at the TU Berlin, the Humboldt-Universität Berlin and what used to be the Institute for Mechanics at the Akademie der Wissenschaften in Chemnitz. By now, a second branch in Munich and two locations in Berlin Adlershof and Oberpfaffenhofen (near Munich) belong to Fraunhofer IZM

About STFI

The Saxon Textile Research Institute (STFI) is a German non-profit research institution in the Free State of Saxony and continues the long standing traditions of the Saxon textile research and textile industry. Founded by 24 enterprises and institutions of the textile industry in 1992, 120 employees are engaged at the STFI today. Process-related and product-related research work covers classical textile technologies as well as innovative technical solutions for a wide range of applications such as geotextiles, textile filters, and nonwovens in automobile sector or heat protective clothing (see also www.stfi.de). Currently, STFI is active in more than 100 national research projects each year and in 10 running EU funded projects. Experts of STFI are working as evaluators for EU-proposals. STFI cooperates closely with European, national and regional authorities to promote industrial R&D and recommends support programs for SMEs.

About CSEM

CSEM, Centre Suisse d’ Electronique et de Microtechnique (Swiss Center for Electronics and Microtechnology), founded in 1984, is a private research and development center specializing in microtechnology, nanotechnology, microelectronics, system engineering and communications technologies. It offers its customers and industry partners tailor-made innovative solutions based on its knowledge of the market and technological expertise derived from applied research. Having founded several start-ups, it contributes to developing Switzerland as an industrial location. To date, a total of 29 such enterprises, with more than 500 employees, have been launched by CSEM. In addition, CSEM has acquired an international dimension by establishing a presence in the Arab Emirates in 2005, and in Brazil in 2007, in order to speed up and encourage the transfer of knowledge and new technologies beneficial to the local economy of these countries. Approximately 400 highly qualified and specialized employees from various scientific and technical disciplines work for CSEM in Neuchâtel, Zurich, Basel, Alpnach and Landquart. They represent more than 30 nationalities and constitute the basis of the company’s creativity, dynamism and innovation potential. Further information is available at www.csem.ch

About PEP

PEP is a private technical centre dedicated to injection moulding of thermoplastics. Since 20 years, PEP offers means, expertises and services on technological, incremental and rupture innovations, particularly regarding injection molding field. Located in the heart of the greatest concentration of companies working in or around polymer processing in France, the PEP staff is composed of more of 50 persons, with a 5 million € turnover. Its activities can be distinguished in three important specialities: Multipartnership R&D programs, Engineering activity, and expertises/services activities dedicated to the whole plastic industry. To realise these works, the PEP relies on a range of equipments, services and competences, dispatched in three business unit : Design & Simulations, Processes & Tools, and Materials.

About ETTLIN

Ettlin Spinnerei und Weberei Produktions GmbH & co. KG (ETTLIN) is located in Ettlingen, a middle sized city in the German Black Forest. It was founded in 1836 as the first public company in the German textile industry. With its 140 employees Ettlin produces 30.000 kg of yarn and 90.000 m2 of fabrics each day. This productivity generates an annual turnover of about 23 Mio. €. Technical textiles stand for 80% of the total turnover. Currently the research and development department is working with new fabric structures for applications with special requirements.

About Peppermint Holding

The PEPPERMINT Holding GmBH is a medium sized German industry and technology group with its headquarters in Berlin. PEPPERMINT designs and produces high-end, innovative textile materials for “emotion”, “mobility”, and “security” technical and fashionable yarns, Jacquard fabrics as well as innovative designs for fashion and home textiles. With its 600 highly qualified employees and state-of-the-art spinning, weaving, finishing and printing facilities, all based in Europe, PEPPERMINT is closely involved in the development of visionary technical applications together with international institutes to supply taior-made solutions to its partners. In the business area technology, PEPPERMINT supports young innovative companies, mostly in the healthcare sector, with venture capital. For more information please visit www.peppermint-vc.de

About Sport Soie

Sport Soie is a French company belonging to a textile group with 600 employees. The consolidated turnover of Sport Soie was more than 73 million euros in 2008. Sport Soie and the other subsidiaries offer their know-how in weaving, engraving, printing, as well as auxiliary services including dying, finishing, making of accessories, coated fabrics. Fashion (ready-to-wear, handbags and luggage, accessories), home furnishings, swimming suits and lingerie are the main markets of the group. With the help of modern, high performance industrial equipment, Sport Soie and the other subsidiaries can provide customized textile solutions to their customers. Always moving forward, Sport Soie’s guiding policy is based on investment, product innovation and constant creation of new developments.

For more information, please click here

Contacts:

Hanne Degans, Imec External Communications Officer, T: +32 16 28 17 69,

Barbara Kalkis, Maestro Marketing & PR, T: +1 408 996 9975,

Copyright © imec

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Sports

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

![]() Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Textiles/Clothing

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

![]() Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

Alliances/Trade associations/Partnerships/Distributorships

![]() Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

Chicago Quantum Exchange welcomes six new partners highlighting quantum technology solutions, from Chicago and beyond September 23rd, 2022

![]() University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

University of Illinois Chicago joins Brookhaven Lab's Quantum Center June 10th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||