Home > Press > Breaking the ice before it begins

|

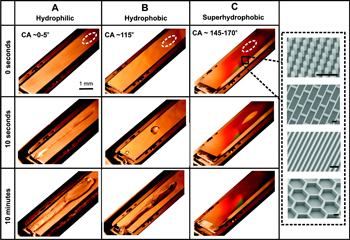

| Ice accumulation on flat aluminum (A), smooth fluorinated Si (B), and microstructured fluorinated Si (C) surfaces. |

Abstract:

Nanostructured materials repel water droplets before they have a chance to freeze

Breaking the ice before it begins

Cambridge, MA | Posted on November 15th, 2010Engineers from Harvard University have designed and demonstrated ice-free nanostructured materials that literally repel water droplets before they even have the chance to freeze.

The finding, reported online in ACS Nano on November 9th, could lead to a new way to keep airplane wings, buildings, powerlines, and even entire highways free of ice during the worst winter weather. Moreover, integrating anti-ice technology right into a material is more efficient and sustainable than conventional solutions like chemical sprays, salt, and heating.

A team led by Joanna Aizenberg, Amy Smith Berylson Professor of Materials Science at the Harvard School of Engineering and Applied Sciences (SEAS) and a Core Member of the Wyss Institute for Biologically Inspired Engineering at Harvard, focused on preventing rather than fighting ice buildup.

"We wanted to take a completely different tact and design materials that inherently prevent ice formation by repelling the water droplets," says Aizenberg. "From past studies, we also realized that the formation of ice is not a static event. The crucial approach was to investigate the entire dynamic process of how droplets impact and freeze on a supercooled surface."

For initial inspiration, the researchers turned to some elegant solutions seen in nature. For example, mosquitos can defog their eyes, and water striders can keep their legs dry thanks to an array of tiny bristles that repel droplets by reducing the surface area each one encounters.

"Freezing starts with droplets colliding with a surface," explains Aizenberg. "But very little is known about what happens when droplets hit surfaces at low temperatures."

To gain a detailed understanding of the process, the researchers watched high-speed videos of supercooled droplets hitting surfaces that were modeled after those found in nature. They saw that when a cold droplet hits the nanostructured surface, it first spreads out, but then the process runs in reverse: the droplet retracts to a spherical shape and bounces back off the surface before ever having a chance to freeze.

By contrast, on a smooth surface without the structured properties, a droplet remains spread out and eventually freezes.

"We fabricated surfaces with various geometries and feature sizes—bristles, blades, and interconnected patterns such as honeycombs and bricks—to test and understand parameters critical for optimization," says Lidiya Mishchenko, a graduate student in Aizenberg's lab and first author of the paper.

The use of such precisely engineered materials enabled the researchers to model the dynamic behavior of impacting droplets at an amazing level of detail, leading them to create a better design for ice-preventing materials.

Another important benefit of testing a wide variety of structures, Mishchenko adds, was that it allowed the team to optimize for pressure-stability. They discovered that the structures composed of interconnected patterns were ideally suited for stable, liquid-repelling surfaces that can withstand high-impact droplet collisions, such as those encountered in driving rain or by planes in flight.

The nanostructured materials prevent the formation of ice even down to temperatures as low as -25 to -30 degrees Celsius. Below that, due to the reduced contact area that prevents the droplets from fully wetting the surface, any ice that forms does not adhere well and is much easier to remove than the stubborn sheets that can form on flat surfaces.

"We see this approach as a radical and much needed shift in anti-ice technologies," says Aizenberg. "The concept of friction-free surfaces that deflect supercooled water droplets before ice nucleation can even occur is more than just a theory or a proof-of-principle experiments. We have begun to test this promising technology in real-world settings to provide a comprehensive framework for optimizing these robust ice-free surfaces for a wide range of applications, each of which may have a specific set of performance requirements."

In comparison with traditional ice prevention or removal methods like salting or heating, the nanostructured materials approach is efficient, non-toxic, and environmentally friendly. Further, when chemicals are used to de-ice a plane, for example, they can be washed away into the environment and their disposal must be carefully monitored. Similarly, salt on roads can lead to corrosion and run-off problems in local water sources.

The researchers anticipate that with their improved understanding of the ice forming process, a new type of coating integrated directly into a variety of materials could soon be developed and commercialized.

In addition to Aizenberg, who is also the Susan S. and Kenneth L. Wallach Professor at the Radcliffe Institute for Advanced Study and a Professor of Chemistry and Chemical Biology at Harvard, and Mishchenko, the co-authors of the paper included Benjamin Hatton and Vaibhav Bahadur, both at SEAS and Wyss, and Ashley Taylor and Tom Krupenkin, both at the University of Wisconsin-Madison.

The researchers acknowledge L. Stirling and A. Grinthal for their valuable contribution and funding from DARPA (Award Number HR0011-08-C-0114); the Wyss Institute for Biologically Inspired Engineering at Harvard University; and the U.S. Department of Homeland Security (DHS) Scholarship and Fellowship Program.

####

For more information, please click here

Contacts:

Michael Patrick Rutter

617-496-3815

Copyright © Harvard University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Automotive/Transportation

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Home

![]() Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

![]() Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

![]() Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Construction

![]() Temperature-sensing building material changes color to save energy January 27th, 2023

Temperature-sensing building material changes color to save energy January 27th, 2023

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||