Home > Press > Organic Photovoltaics Nearing Mass Production

|

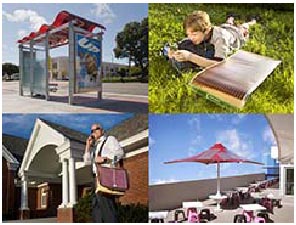

| Current examples of products integrating organic solar cells. (Source: Konarka) |

Abstract:

Bags, Backpacks, Smart Textiles, Umbrellas, Awnings, Tents, and Building Façades first to utilize OPV's.

The latest developments in this field will be on display at LOPE-C in Frankfurt, Germany from May 31 - June 2, 2010.

Organic Photovoltaics Nearing Mass Production

Frankfurt | Posted on December 4th, 2009Organic photovoltaics (OPV) is an innovative solar cell technology based on conductive plastic materials such as polymers. Such devices are fabricated by ultra low-cost, roll-to-roll printing techniques. They are formed by layering extremely thin, photo-active coatings on lightweight, flexible carrier substrates, which are organic in nature as well. OPV is one of the most dynamic, rapidly developing technology segments pertaining to renewable, or green, energy. Despite the current upheaval in world financial markets, OPV continues to gain in economic importance and make steady technical progress. Various OPV technologies are being developed in industrial and academic research cooperatives and project-based partnerships. At this time, OPV is well on its way to broad commercialization, as first products are available on consumer markets. By heavily investing in manufacturing capacity, the OPV industry is gearing up for mass production of a new kind of lowcost, organic and printed micro-electronics. Current trends and the latest developments in this field will be on display at LOPE-C in Frankfurt, Germany from May 31 - June 2, 2010.

Consumer Goods and Utilities for Mass Markets

Organic photovoltaics (OPV) is a key segment of organic and printed electronics. OPV opens up a new and advantageous way of clean electricity generation using lightweight and low-cost solar cells. Their every-day utility will go far beyond today's cell types made of crystalline silicon sealed in relatively heavy glass modules. OPV cells will be an integral part of a broad range of customary, as well as absolutely novel products operated by their own, grid-independent local power - without constraining their originally intended functionalities.

First examples of such solar-enabled consumer products are handbags equipped with flexible organic solar cells. OPV-functionalized bags serve as charging stations for mobile phones and other portable devices carried inside to keep them operational at all times. Other innovative OPV products, forerunners of mass-market consumer and utility goods, are sun shades and umbrellas covered with thin, flexible organic solar cells. While offering shadow, they also provide power for charging laptops and communications devices. Tents, for military purposes or recreational use, are further examples. Next in line are car roofs as solar generators. Then, all larger-size outdoor objects exposed to the sun's radiation. They all may be suited as carriers of large-area organic photovoltaic devices. From there, it's just a small step to another timely concept: realizing the Zero Energy House through "building integrated photovoltaics", or BIPV.

Building Integrated Photovoltaics

Organic photovoltaics enables large-scale solar energy generation directly integrated in roofs and facades. This includes new housing as well as the energetically renovated building stock. Building-integrated photovoltaics, if based on organic and printed electronics, should become an integral part of house construction leading to novel architectural solutions for residential and industrial buildings. Due to its low weight and easy malleability, BIPV should be able to replace today's add on crystalline silicon roof modules.

BIPV cells can be integrated already in the building's design. Forming a second, outer skin, they conform to a building's cubature. This is similar to "smart" fabrics, where organic solar cells excel by their robustness and flexibility without constraining the textiles' original functionality.

"In all these applications, organic and printed photovoltaics can be realized much easier and more cost efficient," says Dr. Klaus Hecker, Managing Director of the Organic Electronics Association (OE-A), a Working Group within VDMA. "Solar cells can now be directly integrated in their intended applications. They become a functional part as well as a design component of a product."

Organic Photovoltaics: from Lab to Fab

Functionally integrated solar local energy generation increases the utility of consumer products and commercial objects. This is the decisive advance that organic photovoltaics will bring about. The most relevant observation in this context is that OPV technology is currently moving out of the R&D stage and is moving towards industrial manufacturing - lab to fab. At LOPE-C 2010 (Large Area Organic and Printed Electronics Convention), the annual conference and exhibition of the OE-A, taking place May 31 to June 2, 2010, organic photovoltaics is set to claim a major share of marketer and investor attention.

"2010 will be the year of OPV moving into initial production for a variety of consumer oriented applications", says Andrew Hannah, CEO of Plextronics in Pittsburgh, Pennsylvania, a leading industry player. A Carnegie-Mellon University spin-off, Plextronics specializes in OPV and OLED (organic light emitting diode) lighting ink products. The market for printed electronic devices, components and systems, according to Andrew Hannah, could surpass $300bn worldwide within the next 20 years. As one of the leading vendors of conductive polymers and organic inks used in the coating processes of OPV modules, Plextronics is currently developing large-scale coating processes to help spur the introduction manufacturing of commercially viable OPV modules.

Heliathek GmbH, located in Ulm and Dresden, Germany, has concluded another round of venture capitalization led by Wellington Partners in the amount of $27m for establishing a production facility for organic solar cells for mobile applications and BIPV. With their OPV tandem cells, Heliathek currently achieves an efficiency of slightly above 6 percent and is planning to utilize a large-area continuous vacuum coating process.

First Consumer Products: Bags and Backpacks

"At LOPE-C 2010, we will see numerous attendees carrying the first available OPV products, such as bags and backpacks," says Thomas Kolbusch, VP of Coatema Coating Machinery GmbH of Dormagen, Germany.

This is an important indicator of OPV nearing marketability, Kolbusch says: "These products are now offered by several new vendors." They serve as a market opener and attract the early adaptors of novel consumer goods based on organic and printed electronics.

Coatema offers a broad range of equipment for the automation of OPV cell manufacture and encapsulation between robust and flexible, yet transparent barrier layers protecting against degradation by oxygen and vapor penetration. Coatema also makes machinery for substrate bonding of organic cells. At LOPE-C 2010, the company will demonstrate a large OPV coating machine. According to Kolbusch, a cumulative installed basis of 2 gigawatts of flexible organic solar cells during 2010 is a realistic forecast. On the other hand, there is no doubt that OPV still has to overcome major challenges. Kolbusch: "Especially BIPV applications will require long-term stability - whereas efficiency, in the light of ultra low-cost manufacturing, is of second priority. We are seeing strong demand for the development of flexible OPV barrier materials at a reasonable cost."

OPV Efficiency Jumps to almost 8 Percent

In terms of efficiency, OPV has recently encountered a major step upwards. Current record holder is Solarmer Energy Inc. of El Monte, California. Their flexible plastic solar panels have reached an independently (NREL) verified efficiency of 7.9 percent. This, of course, pertains to an R&D environment.

Commercially available OPV modules, at this moment, can muster just 3 to 5 percent. Compared to off-the-shelf crystalline silicon solar modules this appears minuscule. But in practice, the OPV cells' low efficiency is more than compensated for by the much larger usable receptor areas due to substantially lower weight and simpler integration to products and industrial objects.

One of the leaders of the OPV industry, Konarka Technologies of Lowell, Massachusetts, has begun marketing, in the fourth quarter of 2009, three standard types of organic solar cells made of its photovoltaic "Power Plastic®" material, delivering a power output of up to 7 watts. In light of this, Konarka has recently expanded its manufacturing capability with a 250,000 square foot facility with 1 gigawatt nameplate capacity. A very popular current consumer market application of Konarka's flexible OPV panels are those popular bags for recharging mobile phones, digital cameras and other small portable devices. With its technology partner Skyshades, Konarka also is marketing larger OPV panels to be integrated in umbrellas. With their higher output, they are able to recharge laptops. These applications are aiming for cafes and hotels, for solar powered awnings and tents.

With another project partner, Arch Aluminum & Glass of Tamarac, Florida, Konarka recently has announced organic cells suited for BIPV. Konarka's "Solar Curtain Wall" consists of a large-area, partly transparent, partly opaque, OPV façade of an industrial building. Each individual module generates 40 watts, yielding a total of 1.5 kWh for the entire wall. The system is operated as test site and pilot for future use.

####

About LOPE-C

LOPE-C (Large Area, Organic & Printed Electronics Convention) is the leading, fully industry-sponsored annual conference and exhibition of organic and printed electronics. LOPE-C presents the economic trends and the scope of scientific achievements in the field. The convention focuses on the production and application of organic and printed electronics, including the latest developments in OPV. On the LOPE-C 2010 show floor, 75+ international exhibitors will present their latest products and demonstrate advanced industrial process technologies "in situ." LOPE-C is held at the Congress Center of Messe Frankfurt, Germany. It is jointly organized by the Organic Electronics Association (OE-A) and Messe Frankfurt Ausstellungen GmbH.

About OE-A

Formed in 2004 as a Working Group within VDMA (German Engineering Federation), the OE-A (Organic Electronics Association) is the foremost professional body representing the worldwide organic and printed electronics industry. With currently more than 120 members throughout Europe, North America, Asia and Australia, OE-A represents the entire industrial value chain, from component manufacturers and materials suppliers, vendors of manufacturing equipment and process metrology, system integrators and academic research organizations, to the end-users. An important activity is to establish and publish the official OE-A Roadmap fixing time lines for applications and technologies of organic and printed electronics. The OE-A Roadmap is currently available in its third edition (2009). www.oe-a.org

About Messe Frankfurt Ausstellungen GmbH

Messe Frankfurt Ausstellungen GmbH is a fully owned subsidiary of Messe Frankfurt GmbH. At an annual turnover of €440m (2008), Messe Frankfurt is the world's largest fair company operating their own fair grounds. The globally active holding operates a worldwide network of 28 daughter companies, five branch offices and 52 international distribution partners and representatives. With this broad-based structure, Messe Frankfurt is present in more than 150 countries, with important industry events in more than 30 locations. In 2008 Messe Frankfurt organized a total of 102 fairs, 60 of which took place in foreign countries.

For more information, please click here

Contacts:

LOPE-C Press Contact

For enquiries regarding LOPE-C 2010 Conference topics and events, speaker interviews, etc. please contact:

Werner Schulz

Phone: +49 (0) 30 81 05 89 59

Copyright © LOPE-C

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Environment

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Sports

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

![]() Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Events/Classes

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

![]() A New Blue: Mysterious origin of the ribbontail ray’s electric blue spots revealed July 5th, 2024

A New Blue: Mysterious origin of the ribbontail ray’s electric blue spots revealed July 5th, 2024

![]() Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Construction

![]() Temperature-sensing building material changes color to save energy January 27th, 2023

Temperature-sensing building material changes color to save energy January 27th, 2023

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||