Home > Press > Graphitic memory techniques advance at Rice

|

Abstract:

Researchers simplify fabrication of nano storage, chip-design tools

Graphitic memory techniques advance at Rice

Houston, TX | Posted on September 9th, 2009Advances by the Rice University lab of James Tour have brought graphite's potential as a mass data storage medium a step closer to reality and created the potential for reprogrammable gate arrays that could bring about a revolution in integrated circuit logic design.

In a paper published in the online journal ACS Nano, Tour and postdoctoral associate Alexander Sinitskii show how they've used industry-standard lithographic techniques to deposit 10-nanometer stripes of amorphous graphite, the carbon-based, semiconducting material commonly found in pencils, onto silicon. This facilitates the creation of potentially very dense, very stable nonvolatile memory for all kinds of digital devices.

With backing from a major manufacturer of memory chips, Tour and his team have pushed the technology forward in several ways since a paper that appeared last November first described two-terminal graphitic memory. While noting advances in other molecular computing techniques that involve nanotubes or quantum dots, he said none of those have yet proved practical in terms of fabrication.

Not so with this simple-to-deposit graphite. "We're using chemical vapor deposition and lithography -- techniques the industry understands," said Tour, Rice's Chao Professor of Chemistry and a professor of mechanical engineering and materials science and of computer science. "That makes this a good alternative to our previous carbon-coated nanocable devices, which perform well but are very difficult to manufacture."

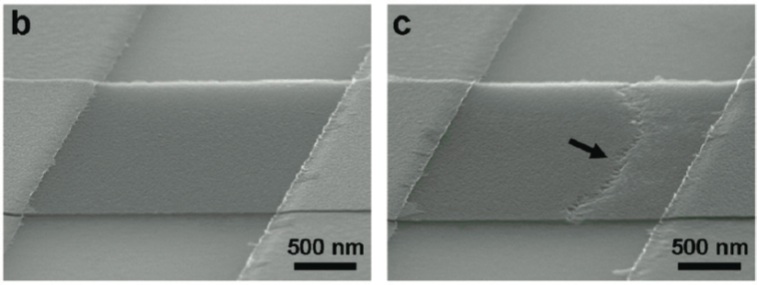

Graphite makes a good, reliable memory "bit" for reasons that aren't yet fully understood. The lab found that running a current through a 10-atom-thick layer of graphite creates a complete break in the circuit -- literally, a gap in the strip a couple of nanometers wide. Another jolt repairs the break. The process appears to be indefinitely repeatable, which provides addressable ones and zeroes, just like today's flash memory devices but at a much denser scale.

Graphite's other advantages were detailed in Tour's earlier work: the ability to operate with as little as three volts, an astoundingly high on/off ratio (the amount of juice a circuit holds when it's on, as opposed to off) and the need for only two terminals instead of three, which eliminates a lot of circuitry. It's also impervious to a wide temperature range and radiation; this makes it suitable for deployment in space and for military uses where exposure to temperature extremes and radiation is a concern.

Tour's graphite-forming technique is well-suited for other applications in the semiconductor industry. One result of the previous paper is a partnership between the Tour group and NuPGA (for "new programmable gate arrays"), a California company formed around the research to create a new breed of reprogrammable gate arrays that could make the design of all kinds of computer chips easier and cheaper.

The Tour lab and NuPGA, led by industry veteran Zvi Or-Bach (founder of eASIC and Chip Express), have applied for a patent based on vertical arrays of graphite embedded in "vias," the holes in integrated circuits connecting the different layers of circuitry. When current is applied to a graphite-filled via, the graphite alternately splits and repairs itself (a process also described in the latest paper), just like it does in strip form. Essentially, it becomes an "antifuse," the basic element of one type of field programmable gate array (FPGA), best described as a blank computer chip that uses software to rewire the hardware.

Currently, antifuse FPGAs can be programmed once. But this graphite approach could allow for the creation of FPGAs that can be reprogrammed at will. Or-Bach said graphite-based FPGAs would start out as blanks, with the graphite elements split. Programmers could "heal" the antifuses at will by applying a voltage, and split them with an even higher voltage.

Such a device would be mighty handy to computer-chip designers, who now spend many millions to create the photolithography mask sets used in chip fabrication. If the design fails, it's back to square one.

"As a result of that, people are only hesitantly investing in new chip designs," said Tour. "They stick with the old chip designs and make modifications. FPGAs are chips that have no specific ability, but you use software to program them by interconnecting the circuitry in different ways." That way, he said, fabricators don't need expensive mask sets to try new designs.

"The No. 1 problem in the industry, and one that gives an opportunity for a company like ours, is that the cost of masks keeps moving up as people push semiconductors into future generators," said Or-Bach. "Over the last 10 years, the cost of a mask set has multiplied almost 10 times.

"If we can really make something that will be an order of magnitude better, the markets will be happy to make use of it. That's our challenge, and I believe the technology makes it possible for us to do that."

The ACS Nano paper appears here:

pubs.acs.org/doi/pdf/10.1021/nn9006225

Read more about Tour's research of graphitic memory here:

www.media.rice.edu/media/NewsBot.asp?MODE=VIEW&ID=11817

####

About Rice University

Rice has from its inception been dedicated to three missions: educating and preparing outstanding students for diverse careers and lives; contributing to the advancement of knowledge across a wide range of fields; and being of service to our city, our state, our nation, and our world. The Call to Conversation posed the question whether our current mission statement fully encompassed our ambitions, particularly our commitment as a research university to creating new knowledge and our obligation to train future leaders across a range of endeavors. It states: “The mission of Rice University, shaped largely by its founder and the first president, is to provide an unsurpassed undergraduate education in science, engineering, the arts, humanities, and social sciences; to produce internationally distinguished scholarship and research and excellent graduate education in carefully focused areas; to ensure that such an education remains affordable; to maintain the distinctive character of a community of learning that is relatively small in scale; and to serve the continuing educational needs of the larger community.”

Based on many conversations and after reviewing the comments on this topic submitted by all segments of our community, it has become clear that although our mission statement describes our three core missions, it does not fully reflect the goals we should now have before us.

For more information, please click here

Contacts:

David Ruth

713-348-6327

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Memory Technology

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Nanoelectronics

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Quantum Dots/Rods

![]() A new kind of magnetism November 17th, 2023

A new kind of magnetism November 17th, 2023

![]() IOP Publishing celebrates World Quantum Day with the announcement of a special quantum collection and the winners of two prestigious quantum awards April 14th, 2023

IOP Publishing celebrates World Quantum Day with the announcement of a special quantum collection and the winners of two prestigious quantum awards April 14th, 2023

![]() Qubits on strong stimulants: Researchers find ways to improve the storage time of quantum information in a spin rich material January 27th, 2023

Qubits on strong stimulants: Researchers find ways to improve the storage time of quantum information in a spin rich material January 27th, 2023

![]() NIST’s grid of quantum islands could reveal secrets for powerful technologies November 18th, 2022

NIST’s grid of quantum islands could reveal secrets for powerful technologies November 18th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||