Home > Press > UNL team's discovery yields supertough, strong nanofibers

|

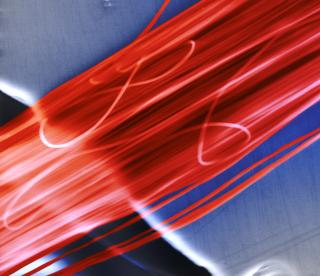

| This high-resolution scanning electron microscopy image shows ultra-tough and strong continuous nanofibers developed by University of Nebraska-Lincoln engineers that can be easily aligned and bundled for handing and processing into various applications. Photo: Joel Brehm, Dimitry Papkov, Yuris Dzenis |

Abstract:

University of Nebraska-Lincoln materials engineers have developed a structural nanofiber that is both strong and tough, a discovery that could transform everything from airplanes and bridges to body armor and bicycles. Their findings are featured on the cover of this week's April issue of the American Chemical Society's journal, ACS Nano.

UNL team's discovery yields supertough, strong nanofibers

Lincoln, NE | Posted on April 24th, 2013"Whatever is made of composites can benefit from our nanofibers," said the team's leader, Yuris Dzenis, McBroom Professor of Mechanical and Materials Engineering and a member of UNL's Nebraska Center for Materials and Nanoscience.

"Our discovery adds a new material class to the very select current family of materials with demonstrated simultaneously high strength and toughness."

In structural materials, conventional wisdom holds that strength comes at the expense of toughness. Strength refers to a material's ability to carry a load. A material's toughness is the amount of energy needed to break it; so the more a material dents, or deforms in some way, the less likely it is to break. A ceramic plate, for example, can carry dinner to the table, but shatters if dropped, because it lacks toughness. A rubber ball, on the other hand, is easily squished out of shape, but doesn't break because it's tough, not strong. Typically, strength and toughness are mutually exclusive.

Dzenis and colleagues developed an exceptionally thin polyacrilonitrile nanofiber, a type of synthetic polymer related to acrylic, using a technique called electrospinning. The process involves applying high voltage to a polymer solution until a small jet of liquid ejects, resulting in a continuous length of nanofiber.

They discovered that by making the nanofiber thinner than had been done before, it became not only stronger, as was expected, but also tougher.

Dzenis suggested that toughness comes from the nanofibers' low crystallinity. In other words, it has many areas that are structurally unorganized. These amorphous regions allow the molecular chains to slip around more, giving them the ability to absorb more energy.

Most advanced fibers have fewer amorphous regions, so they break relatively easily. In an airplane, which uses many composite materials, an abrupt break could cause a catastrophic crash. To compensate, engineers use more material, which makes airplanes, and other products, heavier.

"If structural materials were tougher, one could make products more lightweight and still be very safe," Dzenis said.

Body armor, such as bulletproof vests, also requires a material that's both strong and tough. "To stop the bullet, you need the material to be able to absorb energy before failure, and that's what our nanofibers will do," he said.

Dzenis' co-authors are mechanical and materials engineering colleagues Dimitry Papkov, Yan Zou, Mohammad Nahid Andalib and Alexander Goponenko in UNL's Department of Mechanical and Materials Engineering, and Stephen Z.D. Cheng of the University of Akron, Ohio.

This research was funded by the National Science Foundation, the Air Force Office of Scientific Research and a U.S. Army Research Office Multidisciplinary University Research Initiative grant.

####

For more information, please click here

Contacts:

Yuris Dzenis

402-472-0713

Copyright © University of Nebraska-Lincoln

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Govt.-Legislation/Regulation/Funding/Policy

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Sports

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

Surrey reveals its implantable biosensor that operates without batteries May 22nd, 2020

![]() Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Collagen nanofibrils in mammalian tissues get stronger with exercise December 14th, 2018

Aerospace/Space

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

![]() The National Space Society Congratulates SpaceX on Starship’s 7th Test Flight: Latest Test of the Megarocket Hoped to Demonstrate a Number of New Technologies and Systems January 17th, 2025

The National Space Society Congratulates SpaceX on Starship’s 7th Test Flight: Latest Test of the Megarocket Hoped to Demonstrate a Number of New Technologies and Systems January 17th, 2025

Construction

![]() Temperature-sensing building material changes color to save energy January 27th, 2023

Temperature-sensing building material changes color to save energy January 27th, 2023

![]() Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

Strain-sensing smart skin ready to deploy: Nanotube-embedded coating detects threats from wear and tear in large structures July 15th, 2022

![]() A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

A sunlight-driven “self-healing” anti-corrosion coating May 27th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||