Home > Press > New nanotech fiber: Robust handling, shocking performance: Nanotube fibers have unmatched combination of strength, conductivity, flexibility

|

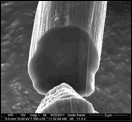

| Nanotubes are tightly packed in the new carbon nanotube fibers produced by Rice University and Teijin Aramid. This cross section of a test fiber, which wastaken with a scanning electron microscope, shows only a few open gaps inside the fiber.

CREDIT: D. Tsentalovich/Rice University |

Abstract:

Rice University's latest nanotechnology breakthrough was more than 10 years in the making, but it still came with a shock. Scientists from Rice, the Dutch firm Teijin Aramid, the U.S. Air Force and Israel's Technion Institute this week unveiled a new carbon nanotube (CNT) fiber that looks and acts like textile thread and conducts electricity and heat like a metal wire. In this week's issue of Science, the researchers describe an industrially scalable process for making the thread like fibers, which outperform commercially available high-performance materials in a number of ways.

New nanotech fiber: Robust handling, shocking performance: Nanotube fibers have unmatched combination of strength, conductivity, flexibility

Houston, TX | Posted on January 10th, 2013"We finally have a nanotube fiber with properties that don't exist in any other material," said lead researcher Matteo Pasquali, professor of chemical and biomolecular engineering and chemistry at Rice. "It looks like black cotton thread but behaves like both metal wires and strong carbon fibers."

The research team includes academic, government and industrial scientists from Rice; Teijin Aramid's headquarters in Arnhem, the Netherlands; the Technion-Israel Institute of Technology in Haifa, Israel; and the Air Force Research Laboratory (AFRL) in Dayton, Ohio.

The phenomenal properties of carbon nanotubes have enthralled scientists from the moment of their discovery in 1991. The hollow tubes of pure carbon, which are nearly as wide as a strand of DNA, are about 100 times stronger than steel at one-sixth the weight. Nanotubes' conductive properties -- for both electricity and heat -- rival the best metal conductors. They also can serve as light-activated semiconductors, drug-delivery devices and even sponges to soak up oil.

Unfortunately, carbon nanotubes are also the prima donna of nanomaterials; they are difficult to work with, despite their exquisite potential. For starters, finding the means to produce bulk quantities of nanotubes took almost a decade. Scientists also learned early on that there were several dozen types of nanotubes -- each with unique material and electrical properties; and engineers have yet to find a way to produce just one type. Instead, all production methods yield a hodgepodge of types, often in hairball-like clumps.

Creating large-scale objects from these clumps of nanotubes has been a challenge. A threadlike fiber that is less than one-quarter the thickness of a human hair will contain tens of millions of nanotubes packed side by side. Ideally, these nanotubes will beperfectly aligned -- like pencils in a box -- and tightly packed. Some labs have explored means of growing such fibers whole, but the production rates for these "solid-state" fibers have proven quite slow compared with fiber-production methods that rely on a chemical process called "wet spinning." In this process, clumps of raw nanotubes are dissolved in a liquid and squirted through tiny holes to form long strands.

Shortly after arriving at Rice in 2000, Pasquali began studying CNT wet-spinning methods with the late Richard Smalley, a nanotechnology pioneer and the namesake of Rice's Smalley Institute for Nanoscale Science and Technology. In 2003, two years before his untimely death, Smalley worked with Pasquali andcolleagues to create the first pure nanotube fibers. The work established an industrially relevant wet-spinning process for nanotubes that was analogous to the methods used to create high-performance aramid fibers -- like Teijin's Twaron -- which are used in bulletproof vests and other products. But the process needed to be refined. The fibers weren't very strong or conductive, due partly to gaps and misalignment of the millions of nanotubes inside them.

"Achieving very high packing and alignment of the carbon nanotubes in the fibers is critical," said study co-author Yeshayahu Talmon, director of Technion's Russell Berrie Nanotechnology Institute, who began collaborating with Pasquali about five years ago.

The next big breakthrough came in 2009, when Talmon, Pasquali and colleagues discovered the first true solvent for nanotubes -- chlorosulfonic acid. For the first time, scientists had a way to create highly concentrated solutions of nanotubes, a development that led to improved alignment and packing.

"Until that time, no one thought that spinning out of chlorosulfonic acid was possible because it reacts with water," Pasquali said. "A graduate student in my lab, Natnael Bahabtu, found simple ways to show that CNT fibers could be spun from chlorosulfonic acid solutions. That was critical for this new process."

Pasquali said other labs had found that the strength and conductivity of spun fibers could also be improved if the starting material -- the clumps of raw nanotubes -- contained long nanotubes with few atomic defects. In 2010, Pasquali and Talmon began experimenting with nanotubes from different suppliers and working with AFRL scientists to measure the precise electrical and thermal properties of the improved fibers.

During the same period, Otto was evaluating methods that different research centers had proposed for making CNT fibers. He envisaged combining Pasquali's discoveries, Teijin Aramid's know-how and the use of long CNTs to further the development of high performance CNT fibers. In 2010, Teijin Aramid set up and funded a project with Rice, and the company's fiber-spinning experts have collaborated with Rice scientists throughout the project.

"The Teijin scientific and technical help led to immediate improvements in strength and conductivity," Pasquali said.

Study co-author Junichiro Kono, a Rice professor of electrical and computer engineering, said, "The research showed that the electrical conductivity of the fibers could be tuned and optimized with techniques that were applied after initial production. This led to the highest conductivity ever reported for a macroscopic CNT fiber."

The fibers reported in Science have about 10 times the tensile strength and electrical and thermal conductivity of the best previously reported wet-spun CNT fibers, Pasquali said. The specific electrical conductivity of the new fibers is on par with copper, gold and aluminum wires, but the new material has advantages over metal wires.

For example, one application where high strength and electrical conductivity could prove useful would be in data and low-power applications, Pasquali said.

"Metal wires will break in rollers and other production machinery if they are too thin," he said. "In many cases, people use metal wires that are far more thick than required for the electrical needs, simply because it's not feasible to produce a thinner wire. Data cables are a particularly good example of this."

Additional co-authors include Behabtu; Rice graduate students Colin Young, Dmitri Tsentalovich and Amram Bengio; Rice postdoctoral researchers Xuan Wang and Anson Ma, now with the University ofConnecticut; Technion's Olga Kleinerman and Yachin Cohen; AFRL's Steven Fairchild, John Ferguson and Benji Maruyama; and Teijin Aramid's Ron ter Waarbeek, Jorrit de Jong and Ron Hoogerwerf.

The research was supported by Teijin Aramid BV, Teijin Limited, AFRL, the Air Force Office of Scientific Research, Technion's Russell Berrie Nanotechnology Institute, the Department of Defense and the Welch Foundation.

"The new CNT fibers have a thermal conductivity approaching that of the best graphite fibers but with 10 times greater electrical conductivity," said study co-author Marcin Otto, business development manager at Teijin Aramid. "Graphite fibers are also brittle, while the new CNT fibers are as flexible and tough as a textile thread. We expect this combination of properties will lead to new products with unique capabilities for the aerospace, automotive, medical and smart-clothing markets."

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies,Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,708 undergraduates and 2,374 graduate students, Rice's undergraduate student-to-faculty ratio is 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 2 for "best value" among private universities by Kiplinger's Personal Finance. To read "What they're saying about Rice," go to tinyurl.com/AboutRice.

Follow Rice News and Media Relations via Twitter @RiceUNews and Teijin Aramid via @TeijinAramid

About Teijin Aramid

Teijin Aramid is a subsidiary of the Teijin Group and a world leader in aramids. Its products Twaron, Sulfron, Teijinconex and Technora are renowned for their strength, sustainability, safety, heat resistance and low weight, and are used in a variety of applications and markets, including automotive, ballistic protection, marine, civil engineering, protective clothing, fiber optic cables and oil and gas. The four high performance fibers are produced in the Netherlands and Japan. For more information, visit www.teijinaramid.com.

Teijin Limited (TSE 3401), the holding company for the Teijin Group, is listed on the Tokyo and Osaka stock exchanges. The group has some 150 companies and around 17,000 employees spread out over 20 countries worldwide. It posted consolidated sales of JPY 854.4 billion (USD $9.9 billion) and total assets of JPY 762.1billion (USD $8.8billion) in the fiscal year ending March 31, 2012. Visit www.teijin.co.jp/english or email M.J. Otto (business development manager) .

For more information, please click here

Contacts:

Jade Boyd

713-348-6778

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Automotive/Transportation

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Textiles/Clothing

![]() Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

Protective equipment with graphene nanotubes meets the strictest ESD safety standards March 25th, 2022

![]() Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

Polymer fibers with graphene nanotubes make it possible to heat hard-to-reach, complex-shaped items February 11th, 2022

![]() Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

Flexible material shows potential for use in fabrics to heat, cool July 3rd, 2020

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||