Home > Press > With simple process, UW-Madison engineers fabricate fastest flexible silicon transistor

|

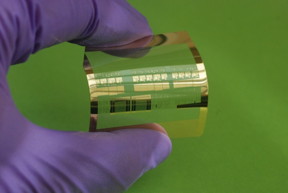

| Using a unique method they developed, a team of UW–Madison engineers has fabricated the world’s fastest silicon-based flexible transistors, shown here on a plastic substrate. COURTESY OF JUNG-HUN SEO |

Abstract:

One secret to creating the world's fastest silicon-based flexible transistors: a very, very tiny knife.

Working in collaboration with colleagues around the country, University of Wisconsin-Madison engineers have pioneered a unique method that could allow manufacturers to easily and cheaply fabricate high-performance transistors with wireless capabilities on huge rolls of flexible plastic.

With simple process, UW-Madison engineers fabricate fastest flexible silicon transistor

Madison, WI | Posted on April 21st, 2016The researchers -- led by Zhenqiang (Jack) Ma, the Lynn H. Matthias Professor in Engineering and Vilas Distinguished Achievement Professor in electrical and computer engineering, and research scientist Jung-Hun Seo -- fabricated a transistor that operates at a record 38 gigahertz, though their simulations show it could be capable of operating at a mind-boggling 110 gigahertz. In computing, that translates to lightning-fast processor speeds.

It's also very useful in wireless applications. The transistor can transmit data or transfer power wirelessly, a capability that could unlock advances in a whole host of applications ranging from wearable electronics to sensors.

The team published details of its advance April 20 in the journal Scientific Reports.

The researchers' nanoscale fabrication method upends conventional lithographic approaches -- which use light and chemicals to pattern flexible transistors -- overcoming such limitations as light diffraction, imprecision that leads to short circuits of different contacts, and the need to fabricate the circuitry in multiple passes.

Using low-temperature processes, Ma, Seo and their colleagues patterned the circuitry on their flexible transistor -- single-crystalline silicon ultimately placed on a polyethylene terephthalate (more commonly known as PET) substrate -- drawing on a simple, low-cost process called nanoimprint lithography.

In a method called selective doping, researchers introduce impurities into materials in precise locations to enhance their properties -- in this case, electrical conductivity. But sometimes the dopant merges into areas of the material it shouldn't, causing what is known as the short channel effect. However, the UW-Madison researchers took an unconventional approach: They blanketed their single crystalline silicon with a dopant, rather than selectively doping it.

Then, they added a light-sensitive material, or photoresist layer, and used a technique called electron-beam lithography -- which uses a focused beam of electrons to create shapes as narrow as 10 nanometers wide -- on the photoresist to create a reusable mold of the nanoscale patterns they desired. They applied the mold to an ultrathin, very flexible silicon membrane to create a photoresist pattern. Then they finished with a dry-etching process -- essentially, a nanoscale knife -- that cut precise, nanometer-scale trenches in the silicon following the patterns in the mold, and added wide gates, which function as switches, atop the trenches.

With a unique, three-dimensional current-flow pattern, the high performance transistor consumes less energy and operates more efficiently. And because the researchers' method enables them to slice much narrower trenches than conventional fabrication processes can, it also could enable semiconductor manufacturers to squeeze an even greater number of transistors onto an electronic device.

Ultimately, says Ma, because the mold can be reused, the method could easily scale for use in a technology called roll-to-roll processing (think of a giant, patterned rolling pin moving across sheets of plastic the size of a tabletop), and that would allow semiconductor manufacturers to repeat their pattern and mass-fabricate many devices on a roll of flexible plastic.

"Nanoimprint lithography addresses future applications for flexible electronics," says Ma, whose work was supported by the Air Force Office of Scientific Research. "We don't want to make them the way the semiconductor industry does now. Our step, which is most critical for roll-to-roll printing, is ready."

###

Additional authors on the paper include Shaoqin (Sarah) Gong of UW-Madison, L. Jay Guo and Tao Ling of the University of Michigan, Weidong Zhou of the University of Texas at Arlington and Alice L. Ma of the University of California, Berkeley.

####

For more information, please click here

Contacts:

Zhenqiang (Jack) Ma

608-261-1095

Renee Meiller

(608) 262-2481

Copyright © University of Wisconsin-Madison

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Flexible Electronics

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

![]() Flexible electronics integrated with paper-thin structure for use in space January 17th, 2025

Flexible electronics integrated with paper-thin structure for use in space January 17th, 2025

![]() Beyond wires: Bubble technology powers next-generation electronics:New laser-based bubble printing technique creates ultra-flexible liquid metal circuits November 8th, 2024

Beyond wires: Bubble technology powers next-generation electronics:New laser-based bubble printing technique creates ultra-flexible liquid metal circuits November 8th, 2024

Wireless/telecommunications/RF/Antennas/Microwaves

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Nanoelectronics

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||