Home > Press > Graphene only as strong as weakest link: Rice, Georgia Tech experiments determine real-world limits of two-dimensional carbon

|

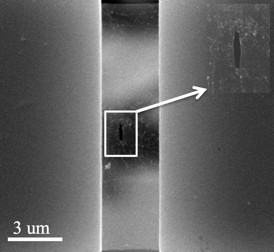

| An electron microscope image shows a pre-crack in a suspended sheet of graphene used to measure the overall strength of the sheet in a test at Rice University. Rice and Georgia Tech scientists performed experiments and theoretical calculations and found that graphene, largely touted for its superior physical strength, is only as strong as its weakest point. Credit: The Nanomaterials, Nanomechanics and Nanodevices Lab/Rice University |

Abstract:

There is no disputing graphene is strong. But new research by Rice University and the Georgia Institute of Technology should prompt manufacturers to look a little deeper as they consider the miracle material for applications.

Graphene only as strong as weakest link: Rice, Georgia Tech experiments determine real-world limits of two-dimensional carbon

Houston, TX | Posted on April 29th, 2014The atom-thick sheet of carbon discovered this century is touted not just for its electrical properties but also for its physical strength and flexibility. The bonds between carbon atoms are well known as the strongest in nature, so a perfect sheet of graphene should withstand just about anything. Reinforcing composite materials is among the material's potential applications.

But materials scientists know perfection is hard to achieve. Researchers Jun Lou at Rice and Ting Zhu at Georgia Tech have measured the fracture toughness of imperfect graphene for the first time and found it to be somewhat brittle. While it's still very useful, graphene is really only as strong as its weakest link, which they determined to be "substantially lower" than the intrinsic strength of graphene.

"Graphene has exceptional physical properties, but to use it in real applications, we have to understand the useful strength of large-area graphene, which is controlled by the fracture toughness," Zhu said.

The researchers reported in the journal Nature Communications the results of tests in which they physically pulled graphene apart to see how much force it would take. Specifically, they wanted to see if graphene follows the century-old Griffith theory that quantifies the useful strength of brittle materials.

It does, Lou said. "Remarkably, in this case, thermodynamic energy still rules," he said.

Imperfections in graphene drastically lessen its strength - with an upper limit of about 100 gigapascals (GPa) for perfect graphene previously measured by nanoindentation - according to physical testing at Rice and molecular dynamics simulations at Georgia Tech. That's important for engineers to understand as they think about using graphene for flexible electronics, composite material and other applications in which stresses on microscopic flaws could lead to failure.

The Griffith criterion developed by a British engineer during World War I describes the relationship between the size of a crack in a material and the force required to make that crack grow. Ultimately, A.A. Griffith hoped to understand why brittle materials fail.

Graphene, it turns out, is no different from the glass fibers Griffith tested.

"Everybody thinks the carbon-carbon bond is the strongest bond in nature, so the material must be very good," Lou said. "But that's not true anymore, once you have those defects. The larger the sheet, the higher the probability of defects. That's well known in the ceramic community."

A defect can be as small as an atom missing from the hexagonal lattice of graphene. But for a real-world test, the researchers had to make a defect of their own - a pre-crack - they could actually see. "We know there will be pinholes and other defects in graphene," he said. "The pre-crack overshadows those defects to become the weakest spot, so I know exactly where the fracture will happen when we pull it.

"The material resistance to the crack growth - the fracture toughness - is what we're measuring here, and that's a very important engineering property," he said.

Just setting up the experiment required several years of work to overcome technical difficulties, Lou said. To suspend it on a tiny cantilever spring stage similar to an atomic force microscopy (AFM) probe, a graphene sheet had to be clean and dry so it would adhere (via van der Waals force) to the stage without compromising the stage movement necessary for the testing. Once mounted, the researchers used a focused ion beam to cut a pre-crack less than 10 percent of the width into the microns-wide section of suspended graphene. Then they pulled the graphene in half, measuring the force required.

While the Rice team was working on the experiment, Zhu and his team performed computer simulations to understand the entire fracture process.

"We can directly simulate the whole deformation process by tracking the motion and displacement with atomic-scale resolution in fairly large samples so our results can be directly correlated with the experiment," said Zhu. "The modeling is tightly coupled with the experiments."

The combination of modeling and experiment provides a level of detail that allowed the researchers to better understand the fracture process - and the tradeoff between toughness and strength in the graphene. What the scientists have learned in the research points out the importance of fabricating high-quality graphene sheets without defects, which could set the stage for fracture.

"Understanding the tradeoff between strength and toughness provides important insights for the future utilization of graphene in structural and functional applications," Zhu added. "This research provides a foundational framework for further study of the mechanical properties of graphene."

Lou said the techniques they used should work for any two-dimensional material. "It's important to understand how defects will affect the handling, processing and manufacture of these materials," he said. "Our work should open up new directions for testing the mechanical properties of 2-D materials."

Co-authors of the paper are graduate students Peng Zhang, Lulu Ma, Phillip Loya and Yongji Gong, and former graduate students Cheng Peng and Jiangnan Zhang, all at Rice; Feifei Fan and Zhi Zeng, graduate students at Georgia Tech; Zheng Liu, an assistant professor at Nanyang Technological University, Singapore, with a complimentary appointment at Rice; Pulickel Ajayan, Rice's Benjamin M. and Mary Greenwood Anderson Professor in Materials Science and Nanoengineering and of Chemistry; and Xingxiang Zhang, a professor at Tianjin Polytechnic University, China.

Lou is an associate professor of materials science and nanoengineering and of chemistry at Rice. Zhu is an associate professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech.

The Welch Foundation, the National Science Foundation, the U.S. Office of Naval Research and the Korean Institute of Machinery and Materials supported the research.

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,920 undergraduates and 2,567 graduate students, Rice's undergraduate student-to-faculty ratio is 6.3-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 2 for "best value" among private universities by Kiplinger's Personal Finance.

Follow Rice News and Media Relations via Twitter @RiceUNews

For more information, please click here

Contacts:

David Ruth

713-348-6327

GEORGIA TECH CONTACT:

John Toon

404-894-6986

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() The Nanomaterials, Nanomechanics and Nanodevices Lab (Lou):

The Nanomaterials, Nanomechanics and Nanodevices Lab (Lou):

![]() Rice University Department of Materials Science and NanoEngineering:

Rice University Department of Materials Science and NanoEngineering:

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||