Home > Press > Ultra-low-power readout architecture for MEMS/NEMS sensors

|

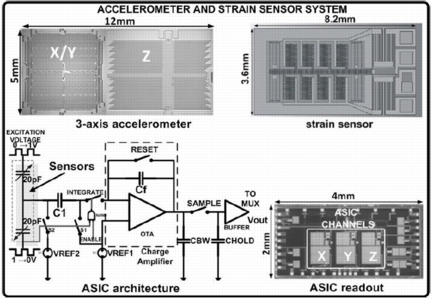

| Figure MEMSreadout: Microphotographs of the accelerometer, strain sensor and readout ASIC and topology of a single channel capacitive readout. |

Abstract:

Imec and Holst Centre report an ultralow-power readout ASIC for capacitive MEMS/NEMS-based sensors. The system can read both accelerometers and strain sensors in a half-bridge configuration. The gain is controlled by integrating pulses from the excitation voltage allowing accurate control of the SNR (signal-to-noise) ratio. We achieved a figure-of-merit of 4.41×10-20 F√(W/Hz) for a sensor range of ±2.0g and ±20,000με over a 100Hz bandwidth. The system has also been designed to cancel residual motion artifacts.

Ultra-low-power readout architecture for MEMS/NEMS sensors

Leuven, Belgium | Posted on August 22nd, 2011With the growing number of MEMS sensors for all types of applications, there is a need for innovative, flexible and power-efficient readout architectures. These have to be able to read signals from a wide range of capacitive devices (such as accelerometers and strain sensors with different actuation voltages, sensitivities and resolutions). One particular interesting application field is the monitoring of building integrity, where the sensors have to measure displacements and stresses, as an indication for the integrity of structures during e.g. seismic events. Such applications impose resolution requirements of 1mg and 10με for the accelerometer and strain sensor respectively, and a range of ±2.0g and ±20,000με over a 100Hz bandwidth.

Most of the existing readout chips are custom-made for a particular sensor, which usually has a large sensitivity in a narrow band. Our architecture can interface with a variety of sensors without jeopardizing the power consumption. This is important for monitoring building integrity, which requires battery-operated systems to keep working for several years. It's also a cost-effective solution, since the same readout can be used for both accelerometers and strain sensors. Last, the system's flexibility is a major asset: sensors with different sensitivities, offsets and mismatch can easily be handled by modifying the timing and duty cycle of the excitation pulses.

Our readout architecture has the lowest reported equivalent acceleration noise level and the highest bandwidth. It offers a unique tradeoff between SNR, bandwidth, and power. The design was fabricated on TSMC 0.25μm CMOS with metal-insulator-metal capacitors. The total power consumption of the 3 channels is 15μW. The clock and excitation voltages for the sensors are external.

####

About IMEC

Imec performs world-leading research in nano-electronics. Imec leverages its scientific knowledge with the innovative power of its global partnerships in ICT, healthcare and energy. Imec delivers industry-relevant technology solutions. In a unique high-tech environment, its international top talent is committed to providing the building blocks for a better life in a sustainable society.

Imec is headquartered in Leuven, Belgium, and has offices in Belgium, the Netherlands, Taiwan, USA, China and Japan. Its staff of about 1,900 people includes more than 500 industrial residents and guest researchers. In 2010, imec's revenue (P&L) was 285 million euro.

Imec is a registered trademark for the activities of IMEC International (a legal entity set up under Belgian law as a "stichting van openbaar nut”), imec Belgium (IMEC vzw supported by the Flemish Government), imec the Netherlands (Stichting IMEC Nederland, part of Holst Centre which is supported by the Dutch Government), imec Taiwan (IMEC Taiwan Co.) and imec China (IMEC Microelectronics (Shangai) Co. Ltd.).

For more information, please click here

Contacts:

Hanne Degans

External Communications Officer

T: +32 16 281 769

Mobile: +32 486 065 175

Copyright © IMEC

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

NEMS

![]() IEDM - CEA-Leti Will Present 11 Papers and Host Workshop on Disruptive Technologies for Data Management November 7th, 2018

IEDM - CEA-Leti Will Present 11 Papers and Host Workshop on Disruptive Technologies for Data Management November 7th, 2018

![]() UT engineers develop first method for controlling nanomotors: Breakthrough for nanotechnology as UT engineers develop first method for switching the mechanical motion of nanomotors September 21st, 2018

UT engineers develop first method for controlling nanomotors: Breakthrough for nanotechnology as UT engineers develop first method for switching the mechanical motion of nanomotors September 21st, 2018

![]() Nano-kirigami: 'Paper-cut' provides model for 3D intelligent nanofabrication July 13th, 2018

Nano-kirigami: 'Paper-cut' provides model for 3D intelligent nanofabrication July 13th, 2018

![]() One string to rule them all April 17th, 2018

One string to rule them all April 17th, 2018

MEMS

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||