Home > Press > 'Amplified' nanotubes may power the future: Rice University lab bulks up raw materials for highly efficient electric grid

|

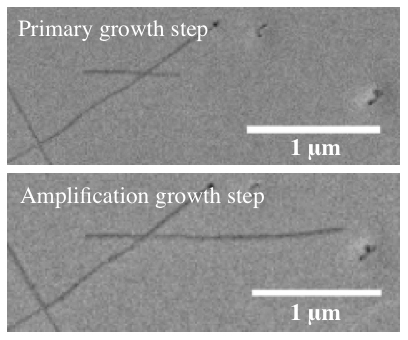

| These images show a single carbon nanotube before and after amplification, a process developed at Rice University seen as key in the development of armchair quantum wire. Such a wire would transmit electricity over great distances with virtually no loss. (Credit: Barron Lab/Rice University) |

Abstract:

Rice University scientists have achieved a pivotal breakthrough in the development of a cable that will make an efficient electric grid of the future possible.

'Amplified' nanotubes may power the future: Rice University lab bulks up raw materials for highly efficient electric grid

Houston, TX | Posted on July 14th, 2011Armchair quantum wire (AQW) will be a weave of metallic nanotubes that can carry electricity with negligible loss over long distances. It will be an ideal replacement for the nation's copper-based grid, which leaks electricity at an estimated 5 percent per 100 miles of transmission, said Rice chemist Andrew R. Barron, author of a paper about the latest step forward published online by the American Chemical Society journal Nano Letters.

A prime technical hurdle in the development of this "miracle cable," Barron said, is the manufacture of massive amounts of metallic single-walled carbon nanotubes, dubbed armchairs for their unique shape. Armchairs are best for carrying current, but can't yet be made alone. They grow in batches with other kinds of nanotubes and have to be separated out, which is a difficult process given that a human hair is 50,000 times larger than a single nanotube.

Barron's lab demonstrated a way to take small batches of individual nanotubes and make them dramatically longer. Ideally, long armchair nanotubes could be cut, re-seeded with catalyst and re-grown indefinitely.

The paper was written by graduate student and first author Alvin Orbaek, undergraduate student Andrew Owens and Barron, the Charles W. Duncan Jr.-Welch Professor of Chemistry and a professor of materials science.

Amplification of nanotubes was seen as a key step toward the practical manufacture of AQW by the late Rice professor, nanotechnology pioneer and Nobel laureate Richard Smalley, who worked closely with Barron and Rice chemist James Tour, the T.T. and W.F. Chao Chair in Chemistry as well as a professor of mechanical engineering and materials science and of computer science, to lay out a path for its development.

Barron charged Orbaek with the task of following through when he joined the lab five years ago. "When I first heard about Rice University, it was because of Rick Smalley and carbon nanotubes," said Orbaek, a native of Ireland. "He had a large global presence with regard to nanotechnology, and that reached me.

"So I was delighted to come here and find I'd be working on nanotube growth that was related to Smalley's work."

Orbaek said he hasn't strayed far from Barron's original direction, which involved chemically attaching an iron/cobalt catalyst to the ends of nanotubes and then fine-tuning the temperature and environment in which amplification could occur.

"My group, with Smalley and Tour's group, demonstrated you could do this -- but in the first demonstration, we got only one tube to grow out of hundreds or thousands," Barron said. Subsequent experiments raised the yield, but tube growth was minimal. In other attempts, the catalyst would literally eat -- or "etch" -- the nanotubes, he said.

Refining the process has taken years, but the payoff is clear because up to 90 percent of the nanotubes in a batch can now be amplified to significant lengths, Barron said. The latest experiments focused on single-walled carbon nanotubes of various chiralities, but the researchers feel the results would be as great, and probably even better, with a batch of pristine armchairs.

The key was finding the right balance of temperatures, pressures, reaction times and catalyst ratios to promote growth and retard etching, Barron said. While initial growth took place at 1,000 degrees Celsius, the researchers found the amplification step required lowering the temperature by 200 degrees, in addition to adjusting the chemistry to maximize the yield.

"What we're getting to is that sweet spot where most of the nanotubes grow and none of them etch," Barron said.

Wade Adams, director of Rice's Richard E. Smalley Institute for Nanoscale Science and Technology and principal investigator on the AQW project, compared the technique to making sourdough bread. "You make a little batch of pure metallics and then amplify that tremendously to make a large amount. This is an important increment in developing the science to make AQW.

Adams noted eight Rice professors and dozens of their students are working on aspects of AQW. "We know how to spin nanotubes into fibers, and their properties are improving rapidly too," he said. "All this now has to come together in a grand program to turn quantum wires into a product that will carry vast amounts of electricity around the world."

Barron and his team are continuing to fine-tune their process and hope that by summer's end they can begin amplifying armchair nanotubes with the goal of making large quantities of pure metallics. "We're always learning more about the mechanisms by which nanotubes grow," said Orbaek, who sees the end game as the development of a single furnace to grow nanotubes from scratch, cap them with new catalyst, amplify them and put out a steady stream of fiber for cables.

"What we've done is a baby step," he said. "But it verifies that, in the big picture, armchair quantum wire is technically feasible."

Orbaek said he is thrilled to play a role in achieving amplification, which Smalley recognized as necessary to his dream of an efficient energy grid that would catalyze solutions to many of the world's problems.

"I'd love to meet him now to say, 'Hey, man, you were right,'" he said.

The Robert A. Welch Foundation and the Air Force Office of Scientific Research funded the research. The Air Force Research Laboratory is primary funding agency for the AQW project.

####

About Rice University

Located on a 285-acre forested campus in Houston, Texas, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is known for its “unconventional wisdom." With 3,485 undergraduates and 2,275 graduate students, Rice's undergraduate student-to-faculty ratio is less than 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review and No. 4 for "best value" among private universities by Kiplinger's Personal Finance. To read "What they're saying about Rice," go to futureowls.rice.edu/images/futureowls/Rice_Brag_Sheet.pdf.

For more information, please click here

Contacts:

David Ruth

Director of National Media Relations

Rice University

Office: 713-348-6327

Cell: 612-702-9473

Facebook: www.facebook.com/DavidRuth | www.facebook.com/RiceUniversity

Twitter: @DavidRuth | @RiceUniversity

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||