Home > Press > Nano research fit for a king

|

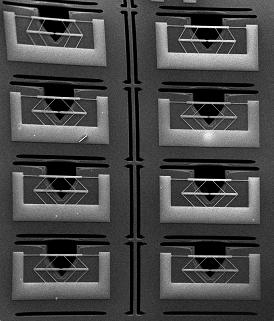

| Rice University researchers invented a micromechanical device on a silicon chip with the ability to measure the tensile and the interface strength of single nanotubes embedded in epoxy. Hundreds of devices can be constructed on a single chip. (Credit: Jun Lou lab/Rice University) |

Abstract:

Rice researchers use a custom-built device to test the tensile and interface strength of single multi-walled carbon nanotubes embedded in epoxy. Such measurements are expected to improve the quality of composite materials.

Nano research fit for a king

Houston, TX | Posted on February 2nd, 2011Arthur pulled a sword from a stone, proving to a kingdom that right beats might. Researchers at Rice University are making the same point in the nanoscale realm.

In this case, the sword is a multiwalled carbon nanotube and the stone is a bead of epoxy.

Knowing precisely how much strength is needed to pull the nanotube from the bead is essential to materials scientists' advancing the art of making stronger, lighter composites for everything from sporting goods to spacecraft.

A team led by Jun Lou, an assistant professor of mechanical engineering and materials science at Rice, and first author Yogeeswaran Ganesan, who recently earned his doctorate in Lou's lab, has published a paper in the American Chemical Society journal Applied Materials and Interfaces describing its work to measure the interface toughness of carbon nanotube-reinforced epoxy composites.

Lou, Ganesan and their colleagues have a second new paper in ACS Nano on using the same technique to measure the effect of nitrogen doping on the mechanical properties of carbon nanotubes.

Nanotubes are finding their way into products as manufacturers bank on their reputation for strength and lightness. One can buy baseball bats, tennis rackets and high-priced bicycles reinforced with nanotubes.

"Carbon nanotubes are so small (a strand of hair is 50,000 times wider) that in order to use them on the human scale, you have to do something to make them bigger," Lou said.

One such way is to mix them into composites, an imperfect science that involves much trial and error since the possible strength of the interface between every type of nanotube and every type of base material is not well understood. Lou and his team intend to eliminate the guesswork with a way to measure important properties of a composite before the first batch is mixed.

"You don't want to spend a lot of time and money on a fancy chemical treatment without knowing what's happening at the critical interface," Lou said.

Single-fiber pullout tests have been used since the early days of composite manufacturing to measure not only the strength of a bond but when, why and how it will break. That's hard on the nanoscale. Others have used atomic force microscopes as part of the pulling mechanism, but the method has its limitations, Lou said.

The Rice team has built a better device: a spring-loaded, push-pull micromechanical assembly on a silicon chip that allows researchers to string a multiwalled nanotube to a blanket of epoxy on one side while the other is held firmly in place with a platinum anchor. Pressing down on the spring applies equal force to both sides, allowing researchers to see just how much is needed to pull the tube from the epoxy.

The team reported in the first paper that forces binding multiwalled nanotubes to a general-purpose epoxy called Epon 828 were actually weaker than they expected. "We have started to understand that adding nanotubes to bulk material doesn't always give you better properties," Lou said. "You have to be very careful about how you add them in and what kind interface they form."

Because batches of nanotubes tend to stick together, some manufacturers functionalize their surfaces to disperse them before mixing into a material. "But that can disrupt the outer wall, and that's a bad thing," Lou said. "If you do something to make nanotubes easily dispersible but decrease their intrinsic strength, you're shooting yourself in the foot."

On the other hand, he said, "If manufacturers need a tough material that absorbs energy without breaking, a weaker interface may not be a bad thing. During this pullout process, there's a lot of friction at the interface of the nanotube and the matrix, and friction is effectively a way to dissipate energy."

Sometimes the end product is better if the nanotube stretches before it breaks. In the ACS Nano paper, the team compared the tensile strength of pristine versus nitrogen-doped multiwalled carbon nanotubes. They found the pristine tubes tend to snap in a brittle fashion, while nitrogen-doped tubes exhibit signs of plasticity -- "necking" before they break.

That may be desirable for certain materials, Lou said. "You don't build a bridge out of ceramic. You build it out of steel because of its plasticity.

"If we can develop a nanotube composite with room-temperature plasticity, it's going to be fantastic," he said. "It will find many, many uses."

Lou said Rice's versatile technique for carrying out nanomechanical experiments is poised to find many long-sought answers. "Developing an ability to engineering nanocomposites with mechanical properties tailored for specific applications is the proverbial holy grail of all structural nanocomposite research," Ganesan said. "The technique essentially takes us one step closer to achieving this goal."

Co-authors of the Applied Materials and Interfaces paper include graduate students Cheng Peng, Phillip Loya and Padraig Moloney; Yang Lu, a recent Ph.D graduate from Lou's lab; Enrique Barrera, a professor of mechanical engineering and materials science; Boris Yakobson, a professor in mechanical engineering and materials science and of chemistry, and James Tour, T.T. and W.F. Chao Chair in Chemistry as well as a professor of mechanical engineering and materials science and of computer science, all of Rice; and Roberto Ballarini, James L. Record Professor and Head of the Department of Civil Engineering at the University of Minnesota, Minneapolis.

Authors of the ACS Nano paper included Lou, Ganesan, Peng, Lu, former postdoc researcher Lijie Ci, visiting professor Anchal Srivastava, and Pulickel Ajayan, a Rice professor in mechanical engineering and materials science and of chemistry.

The National Science Foundation, the Welch Foundation and the Air Force Research Laboratory supported the research behind both papers.

Read the abstract of the Applied Materials and Interfaces paper at pubs.acs.org/doi/abs/10.1021/am1011047

Read the abstract of the ACS Nano paper at pubs.acs.org/doi/abs/10.1021/nn102372w

A video of the pullout process is available at www.youtube.com/watch?v=ompRhXaR7Ic

####

About Rice University

Located in Houston, Rice University is consistently ranked among the nation's top 20 universities by U.S. News & World Report. A Tier One research university known for its "unconventional wisdom," Rice has schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and offers its 3,485 undergraduates and 2,275 graduate students a wide range of majors. Rice has the sixth-largest endowment per student among American private research universities and is rated No. 4 for “best value” among private universities by Kiplinger’s Personal Finance. Its undergraduate student-to-faculty ratio is less than 6-to-1. With a residential college system that builds close-knit and diverse communities and collaborative culture, Rice has been ranked No. 1 for best quality of life multiple times by the Princeton Review.

For more information, please click here

Contacts:

David Ruth

713-348-6327

Mike Williams

713-348-6728

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Academic/Education

![]() Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

Rice University launches Rice Synthetic Biology Institute to improve lives January 12th, 2024

![]() Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Multi-institution, $4.6 million NSF grant to fund nanotechnology training September 9th, 2022

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||