Home > Press > Caltech researchers design a new nanomesh material: Silicon-based film may lead to efficient thermoelectric devices

|

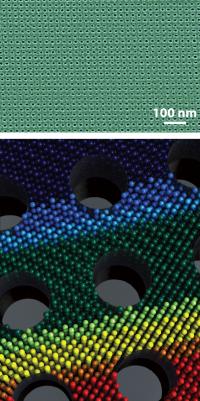

| Top: A scanning electron microscope image shows the grid of tiny holes in the nanomesh material. Bottom: In this drawing, each sphere represents a silicon atom in the nanomesh. The colorful bands show the temperature differences on the material, with red being hotter and blue being cooler.

Credit: Heath group/Caltech |

Abstract:

Computers, light bulbs, and even people generate heat—energy that ends up being wasted. With a thermoelectric device, which converts heat to electricity and vice versa, you can harness that otherwise wasted energy. Thermoelectric devices are touted for use in new and efficient refrigerators, and other cooling or heating machines. But present-day designs are not efficient enough for widespread commercial use or are made from rare materials that are expensive and harmful to the environment.

Caltech researchers design a new nanomesh material: Silicon-based film may lead to efficient thermoelectric devices

Pasadena, CA | Posted on September 23rd, 2010Researchers at the California Institute of Technology (Caltech) have developed a new type of material—made out of silicon, the second most abundant element in Earth's crust—that could lead to more efficient thermoelectric devices. The material—a type of nanomesh—is composed of a thin film with a grid-like arrangement of tiny holes. This unique design makes it difficult for heat to travel through the material, lowering its thermal conductivity to near silicon's theoretical limit. At the same time, the design allows electricity to flow as well as it does in unmodified silicon.

"In terms of controlling thermal conductivity, these are pretty sophisticated devices," says James Heath, the Elizabeth W. Gilloon Professor and professor of chemistry at Caltech, who led the work. A paper about the research will be published in the October issue of the journal Nature Nanotechnology.

A major strategy for making thermoelectric materials energy efficient is to lower the thermal conductivity without affecting the electrical conductivity, which is how well electricity can travel through the substance. Heath and his colleagues had previously accomplished this using silicon nanowires—wires of silicon that are 10 to 100 times narrower than those currently used in computer microchips. The nanowires work by impeding heat while allowing electrons to flow freely.

In any material, heat travels via phonons—quantized packets of vibration that are akin to photons, which are themselves quantized packets of light waves. As phonons zip along the material, they deliver heat from one point to another. Nanowires, because of their tiny sizes, have a lot of surface area relative to their volume. And since phonons scatter off surfaces and interfaces, it is harder for them to make it through a nanowire without bouncing astray. As a result, a nanowire resists heat flow but remains electrically conductive.

But creating narrower and narrower nanowires is effective only up to a point. If the nanowire is too small, it will have so much relative surface area that even electrons will scatter, causing the electrical conductivity to plummet and negating the thermoelectric benefits of phonon scattering.

To get around this problem, the Caltech team built a nanomesh material from a 22-nanometer-thick sheet of silicon. (One nanometer is a billionth of a meter.) The silicon sheet is converted into a mesh—similar to a tiny window screen—with a highly regular array of 11- or 16-nanometer-wide holes that are spaced just 34 nanometers apart.

Instead of scattering the phonons traveling through it, the nanomesh changes the way those phonons behave, essentially slowing them down. The properties of a particular material determine how fast phonons can go, and it turns out that—in silicon at least—the mesh structure lowers this speed limit. As far as the phonons are concerned, the nanomesh is no longer silicon at all. "The nanomesh no longer behaves in ways typical of silicon," says Slobodan Mitrovic, a postdoctoral scholar in chemistry at Caltech. Mitrovic and Caltech graduate student Jen-Kan Yu are the first authors on the Nature Nanotechnology paper.

When the researchers compared the nanomesh to the nanowires, they found that—despite having a much higher surface-area-to-volume ratio—the nanowires were still twice as thermally conductive as the nanomesh. The researchers suggest that the decrease in thermal conductivity seen in the nanomesh is indeed caused by the slowing down of phonons, and not by phonons scattering off the mesh's surface. The team also compared the nanomesh to a thin film and to a grid-like sheet of silicon with features roughly 100 times larger than the nanomesh; both the film and the grid had thermal conductivities about 10 times higher than that of the nanomesh.

Although the electrical conductivity of the nanomesh remained comparable to regular, bulk silicon, its thermal conductivity was reduced to near the theoretical lower limit for silicon. And the researchers say they can lower it even further. "Now that we've showed that we can slow the phonons down," Heath says, "who's to say we can't slow them down a lot more?"

The researchers are now experimenting with different materials and arrangements of holes in order to optimize their design. "One day, we might be able to engineer a material where you not only can slow the phonons down, but you can exclude the phonons that carry heat altogether," Mitrovic says. "That would be the ultimate goal."

The other authors on the paper, "Reduction of thermal conductivity in phononic nanomesh structures," are Caltech graduate students Douglas Tham and Joseph Varghese. The research was funded by the Department of Energy, the Intel Foundation, a Scholar Award from the King Abdullah University of Science and Technology, and the National Science Foundation.

####

For more information, please click here

Contacts:

Kathy Svitil

626-395-8022

Copyright © California Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||