Home > Press > No limit yet for carbon nanotube fibers: Rice lab makes case for high-performance carbon nanotube fibers for industry

|

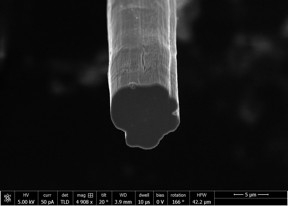

| The cross section of a fiber produced at Rice University contains tens of millions of carbon nanotubes. The lab continually improves its method to make fibers, which tests show are now stronger than Kevlar. (Credit: Pasquali Research Group/Rice University) |

Abstract:

Carbon nanotube fibers made at Rice University are now stronger than Kevlar and are inching up on the conductivity of copper.

No limit yet for carbon nanotube fibers: Rice lab makes case for high-performance carbon nanotube fibers for industry

Houston, TX | Posted on August 17th, 2020The Rice lab of chemical and biomolecular engineer Matteo Pasquali reported in Carbon it has developed its strongest and most conductive fibers yet, made of long carbon nanotubes through a wet spinning process.

In the new study led by Rice graduate students Lauren Taylor and Oliver Dewey, the researchers noted that wet-spun carbon nanotube fibers, which could lead to breakthroughs in a host of medical and materials applications, have doubled in strength and conductivity every three years, a trend that spans almost two decades.

While that may never mimic Moore’s Law, which set a benchmark for computer chip advances for decades, Pasquali and his team are doing their part to advance the method they pioneered to make carbon nanotube fibers.

The lab’s threadlike fibers, with tens of millions of nanotubes in cross section, are being studied for use as bridges to repair damaged hearts, as electrical interfaces with the brain, for use in cochlear implants, as flexible antennas and for automotive and aerospace applications.

They are also part of the Carbon Hub, a multiuniversity research initiative launched in 2019 by Rice with support from Shell, Prysmian and Mitsubishi to create a zero-emissions future.

“Carbon nanotube fibers have long been touted for their potential superior properties,” Pasquali said. “Two decades of research at Rice and elsewhere have made this potential a reality. Now we need a worldwide effort to increase production efficiency so these materials could be made with zero carbon dioxide emissions and potentially with concurrent production of clean hydrogen.”

“The goal of this paper is to put forth the record properties of the fibers produced in our lab,” Taylor said. “These improvements mean we’re now surpassing Kevlar in terms of strength, which for us is a really big achievement. With just another doubling, we would surpass the strongest fibers on the market.”

The flexible Rice fibers have a tensile strength of 4.2 gigapascals (GPa), compared to 3.6 GPa for Kevlar fibers. The fibers require long nanotubes with high crystallinity; that is, regular arrays of carbon-atom rings with few defects. The acidic solution used in the Rice process also helps reduce impurities that can interfere with fiber strength and enhances the nanotubes’ metallic properties through residual doping, Dewey said.

“The length, or aspect ratio, of the nanotubes is the defining characteristic that drives the properties in our fibers,” he said, noting the surface area of the 12-micrometer nanotubes used in Rice fiber facilitates better van der Waals bonds. “It also helps that the collaborators who grow our nanotubes optimize for solution processing by controlling the number of metallic impurities from the catalyst and what we call amorphous carbon impurities.”

The researchers said the fibers’ conductivity has improved to 10.9 megasiemens (million siemens) per meter. “This is the first time a carbon nanotube fiber has passed the 10 megasiemens threshold, so we’ve achieved a new order of magnitude for nanotube fibers,” Dewey said. Normalized for weight, he said the Rice fibers achieve about 80% of the conductivity of copper.

“But we’re surpassing platinum wire, which is a big achievement for us,” Taylor said, “and the fiber thermal conductivity is better than any metal and any synthetic fibers, except for pitch graphite fibers.”

The lab’s goal is to make the production of superior fibers efficient and inexpensive enough to be incorporated by industry on a large scale, Dewey said. Solution processing is common in the production of other kinds of fibers, including Kevlar, so factories could use familiar processes without major retooling.

“The benefit of our method is that it’s essentially plug-and-play,” he said. “It’s inherently scalable and fits in with the way synthetic fibers are already made.”

“There's a notion that carbon nanotubes are never going to be able to obtain all the properties that people have been hyping now for decades,” Taylor said. “But we're making good gains year over year. It’s not easy, but we still do believe this technology is going to change the world.”

Co-authors of the paper are Rice alumnus Robert Headrick; graduate students Natsumi Komatsu and Nicolas Marquez Peraca; Geoff Wehmeyer, an assistant professor of mechanical engineering; and Junichiro Kono, the Karl F. Hasselmann Professor in Engineering and a professor of electrical and computer engineering, of physics and astronomy, and of materials science and nanoengineering. Pasquali is the A.J. Hartsook Professor of Chemical and Biomolecular engineering, of chemistry and of materials science and nanoengineering.

The U.S. Air Force Office of Scientific Research, the Robert A. Welch Foundation, the Department of Energy’s Advanced Manufacturing Office and the Advanced Research Projects Agency-Energy supported the research.

####

About Rice University

Located on a 300-acre forested campus in Houston, Rice University is consistently ranked among the nation’s top 20 universities by U.S. News & World Report. Rice has highly respected schools of Architecture, Business, Continuing Studies, Engineering, Humanities, Music, Natural Sciences and Social Sciences and is home to the Baker Institute for Public Policy. With 3,962 undergraduates and 3,027 graduate students, Rice’s undergraduate student-to-faculty ratio is just under 6-to-1. Its residential college system builds close-knit communities and lifelong friendships, just one reason why Rice is ranked No. 1 for lots of race/class interaction and No. 4 for quality of life by the Princeton Review. Rice is also rated as a best value among private universities by Kiplinger’s Personal Finance.

Follow Rice News and Media Relations via Twitter @RiceUNews.

For more information, please click here

Contacts:

Jeff Falk

713-348-6775

Mike Williams

713-348-6728

Copyright © Rice University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Engineers make first pure nanotube fibers:

Engineers make first pure nanotube fibers:

![]() New nanotech fiber: Robust handling, shocking performance:

New nanotech fiber: Robust handling, shocking performance:

![]() George R. Brown School of Engineering:

George R. Brown School of Engineering:

![]() Wiess School of Natural Sciences:

Wiess School of Natural Sciences:

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() New discovery aims to improve the design of microelectronic devices September 13th, 2024

New discovery aims to improve the design of microelectronic devices September 13th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||