Home > Press > Now made in Japan – Asian battery manufacturers welcome highly conductive nanotube additive

|

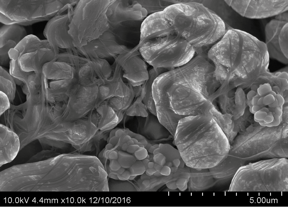

| Electrode sample with 0.06% of TUBALLTM shows good coverage of the particle’s surface |

Abstract:

Kusumoto Chemicals, one of the leading chemical companies in Japan, is the first to launch local industrial production of TUBALL™ BATT – an innovative single wall carbon nanotube additive for Li-ion batteries. This additive solves the key problem of high-energy silicon anodes – poor cycle life – and is thus, for first time ever, enabling their industrial adoption for electric vehicles. Large-scale Japanese battery manufacturers are eagerly awaiting the first nanotube-based products from this new production facility.

Now made in Japan – Asian battery manufacturers welcome highly conductive nanotube additive

Luxembourg | Posted on March 7th, 2019Japan has became a pioneer in launching the first Asian production facility for ready-to-use single wall carbon nanotube solutions for Li-ion batteries. This is in keeping with the country’s reputation for technical innovation and its unrivalled commitment to quality, with many of the world’s leading lithium-ion battery players headquartered there.

In an exclusive deal with OCSiAl, the leader in single wall carbon nanotube synthesis and development of related technical solutions, Kusumoto Chemicals has launched a facility to produce TUBALL BATT – an advanced nanotube-based additive. At the moment, the production facility is operating in a commissioning and testing mode. By the end of the year, Kusumoto Chemicals plans to produce a volume of TUBALL BATT that, in terms of increased battery energy density, would be equivalent to a medium-size battery manufacturer's capacity, with further significant increases in production capacity in the following years.

TUBALL BATT is the first ready-to-use solution with TUBALL single wall carbon nanotubes for both anodes and cathodes. As little as 100 g of TUBALL nanotubes in the cathode is sufficient for an entire EV battery pack, replacing about 3–4 kg of carbon black. When added to a silicon anode, nanotubes solve the key problem of this material – poor cycle life. Dr Jian Lin, Vice President of R&D at Shenzhen BAK Power Battery (which ranks among the top 10 battery manufacturers worldwide) confirms the fact that it is currently the only solution able to reach targeted requirements for silicon anodes to be used for electric vehicles. “Single wall carbon nanotubes can improve the cycling performance to a very great, huge extent. I think that they have the biggest advantage for application in silicon anodes, compared with other additives,” he said.

Large-scale Japanese Li-ion battery manufacturers are eagerly awaiting the first nanotube-based products from this brand-new production facility. “The start of manufacturing is a big step towards establishing stable, high-quality and cost-effective supply of this high-performance additive to our key customers on the local market,” a Kusumoto Chemicals representative noted.

The TUBALL BATT production network is expected to grow extremely rapidly in the Asian market. In addition to this recently launched Kusumoto Chemicals facility, two more plants will be commissioned this year in China, which is the world’s largest battery market.

####

For more information, please click here

Contacts:

Anastasia Zirka

PR & Advertising manager

OCSiAl Group

+7 913 989 9239

Copyright © OCSiAl Group

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

New-Contracts/Sales/Customers

![]() Bruker Light-Sheet Microscopes at Major Comprehensive Cancer Center: New Advanced Imaging Center Powered by Two MuVi and LCS SPIM Microscopes March 25th, 2021

Bruker Light-Sheet Microscopes at Major Comprehensive Cancer Center: New Advanced Imaging Center Powered by Two MuVi and LCS SPIM Microscopes March 25th, 2021

![]() Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

![]() Veeco Announces Aledia Order of 300mm MOCVD Equipment for microLED Displays: Propel™ Platform First 300mm System with EFEM Designed for Advanced Display Applications October 20th, 2020

Veeco Announces Aledia Order of 300mm MOCVD Equipment for microLED Displays: Propel™ Platform First 300mm System with EFEM Designed for Advanced Display Applications October 20th, 2020

![]() GREENWAVES TECHNOLOGIES Announces Next Generation GAP9 Hearables Platform Using GLOBALFOUNDRIES 22FDX Solution October 16th, 2020

GREENWAVES TECHNOLOGIES Announces Next Generation GAP9 Hearables Platform Using GLOBALFOUNDRIES 22FDX Solution October 16th, 2020

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||