Home > Press > Future electronic components to be printed like newspapers

|

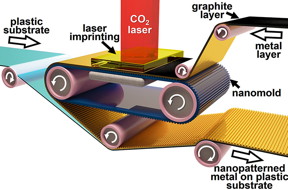

| Roll-to-roll laser-induced superplasticity, a new fabrication method, prints metals at the nanoscale needed for making electronic devices ultrafast. (Purdue University image/Ramses Martinez) |

Abstract:

Roll-to-Roll Nanoforming of Metals Using Laser-Induced Superplasticity

Debkalpa Goswami , Juan C. Munera, Aniket Pal, Behnam Sadri, Caio Lui P. G. Scarpetti, Ramses V. Martinez

Purdue University, West Lafayette, IN, USA

doi: 10.1021/acs.nanolett.8b00714

This Letter describes a low-cost, scalable nanomanufacturing process that enables the continuous forming of thin metallic layers with nanoscale accuracy using roll-to-roll, laser-induced superplasticity (R2RLIS). R2RLIS uses a laser shock to induce the ultrahigh-strain-rate deformation of metallic films at room temperature into low-cost polymeric nanomolds, independently of the original grain size of the metal. This simple and inexpensive nanoforming method does not require access to cleanrooms and associated facilities, and can be easily implemented on conventional CO2 lasers, enabling laser systems commonly used for rapid prototyping or industrial cutting and engraving to fabricate uniform and three-dimensional crystalline metallic nanostructures over large areas. Tuning the laser power during the R2RLIS process enables the control of the aspect ratio and the mechanical and optical properties of the fabricated nanostructures. This roll-to-roll technique successfully fabricates mechanically strengthened gold plasmonic nanostructures with aspect ratios as high as 5 that exhibit high oxidation resistance and strong optical field enhancements. The CO2 laser used in R2RLIS can also integrate the fabricated nanostructures on transparent flexible substrates with robust interfacial contact. The ability to fabricate ultrasmooth metallic nanostructures using roll-to-roll manufacturing enables the large scale production, at a relatively low-cost, of flexible plasmonic devices toward emerging applications.

Future electronic components to be printed like newspapers

West Lafayette, IN | Posted on July 20th, 2018A new manufacturing technique uses a process similar to newspaper printing to form smoother and more flexible metals for making ultrafast electronic devices.

The low-cost process, developed by Purdue University researchers, combines tools already used in industry for manufacturing metals on a large scale, but uses the speed and precision of roll-to-roll newspaper printing to remove a couple of fabrication barriers in making electronics faster than they are today.

Cellphones, laptops, tablets, and many other electronics rely on their internal metallic circuits to process information at high speed. Current metal fabrication techniques tend to make these circuits by getting a thin rain of liquid metal drops to pass through a stencil mask in the shape of a circuit, kind of like spraying graffiti on walls.

"Unfortunately, this fabrication technique generates metallic circuits with rough surfaces, causing our electronic devices to heat up and drain their batteries faster," said Ramses Martinez, assistant professor of industrial engineering and biomedical engineering.

Future ultrafast devices also will require much smaller metal components, which calls for a higher resolution to make them at these nanoscale sizes.

"Forming metals with increasingly smaller shapes requires molds with higher and higher definition, until you reach the nanoscale size," Martinez said. "Adding the latest advances in nanotechnology requires us to pattern metals in sizes that are even smaller than the grains they are made of. It's like making a sand castle smaller than a grain of sand."

This so-called "formability limit" hampers the ability to manufacture materials with nanoscale resolution at high speed.

Purdue researchers have addressed both of these issues – roughness and low resolution – with a new large-scale fabrication method that enables the forming of smooth metallic circuits at the nanoscale using conventional carbon dioxide lasers, which are already common for industrial cutting and engraving.

"Printing tiny metal components like newspapers makes them much smoother. This allows an electric current to travel better with less risk of overheating," Martinez said.

The fabrication method, called roll-to-roll laser-induced superplasticity, uses a rolling stamp like the ones used to print newspapers at high speed. The technique can induce, for a brief period of time, "superelastic" behavior to different metals by applying high-energy laser shots, which enables the metal to flow into the nanoscale features of the rolling stamp – circumventing the formability limit.

"In the future, the roll-to-roll fabrication of devices using our technique could enable the creation of touch screens covered with nanostructures capable of interacting with light and generating 3D images, as well as the cost-effective fabrication of more sensitive biosensors," Martinez said.

The researchers discuss their technology further in Nano Letters, an American Chemical Society publication. The work is financially supported by Purdue University; the Ross Fellowship program at Purdue; the Administrative Department of Science, Technology and Innovation of Colombia (Grant 567-2012); and Procter & Gamble (Grant 209621).

####

For more information, please click here

Contacts:

Writer: Kayla Wiles

765-494-2432

Source: Ramses Martinez

765-496-7693

Copyright © Purdue University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Display technology/LEDs/SS Lighting/OLEDs

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() Efficient and stable hybrid perovskite-organic light-emitting diodes with external quantum efficiency exceeding 40 per cent July 5th, 2024

Efficient and stable hybrid perovskite-organic light-emitting diodes with external quantum efficiency exceeding 40 per cent July 5th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() New discovery aims to improve the design of microelectronic devices September 13th, 2024

New discovery aims to improve the design of microelectronic devices September 13th, 2024

Photonics/Optics/Lasers

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||