Home > Press > New 4-D printer could reshape the world we live in

|

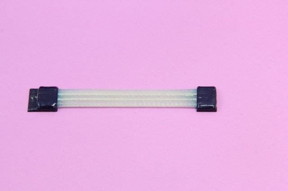

| A powerful new 4-D printing technique could one day allow manufacturers to produce electronic devices and their wiring in a single process. Credit: H. Jerry Qi |

Abstract:

From moon landings to mobile phones, many of the farfetched visions of science fiction have transformed into reality. In the latest example of this trend, scientists report that they have developed a powerful printer that could streamline the creation of self-assembling structures that can change shape after being exposed to heat and other stimuli. They say this unique technology could accelerate the use of 4-D printing in aerospace, medicine and other industries.

New 4-D printer could reshape the world we live in

New Orleans, LA | Posted on March 20th, 2018The researchers are presenting their work today at the 255th National Meeting & Exposition of the American Chemical Society (ACS). ACS, the world’s largest scientific society, is holding the meeting here through Thursday. It features more than 13,000 presentations on a wide range of science topics.

“We are on the cusp of creating a new generation of devices that could vastly expand the practical applications for 3-D and 4-D printing,” H. Jerry Qi, Ph.D., says. “Our prototype printer integrates many features that appear to simplify and expedite the processes used in traditional 3-D printing. As a result, we can use a variety of materials to create hard and soft components at the same time, incorporate conductive wiring directly into shape-changing structures, and ultimately set the stage for the development of a host of 4-D products that could reshape our world.”

4-D printing is an emerging technology that allows 3-D-printed components to change their shape over time after exposure to heat, light, humidity and other environmental triggers. However, 4-D printing remains challenging, in part because it often requires complex and time-consuming post-processing steps to mechanically program each component. In addition, many commercial printers can only print 4-D structures composed of a single material.

Last year, Qi and his colleagues at Georgia Institute of Technology, in collaboration with scientists at the Singapore University of Technology and Design, used a composite made from an acrylic and an epoxy along with a commercial printer and a heat source to create 4-D objects, such as a flower that can close its petals or a star that morphs into a dome. These objects transformed shape up to 90 percent faster than previously possible because the scientists incorporated the tedious mechanical programming steps directly into the 3-D printing process. Building on this work, the researchers sought to develop an all-in-one printer to address other 4-D printing challenges and move the technology closer to practical application.

The machine they ultimately devised combines four different printing techniques, including aerosol, inkjet, direct ink write and fused deposition modeling. It can handle a multitude of stiff and elastic materials including hydrogels, silver nanoparticle-based conductive inks, liquid crystal elastomers and shape memory polymers, or SMPs. SMPs, which are the most common substances used in 4-D printing, can be programmed to “remember” a shape and then transform into it when heated. With this new technology, the researchers can print higher-quality SMPs capable of making more intricate shape changes than in the past, opening the door for a multitude of functional 4-D applications and designs.

The researchers can also use the printer to project a range of white, gray or black shades of light to form and cure a component into a solid. This grayscale lighting triggers a crosslinking reaction that can alter the component’s behavior, depending on the grayscale of shade shined on it. So, for example, a brighter light shade creates a part that is harder, while a darker shade produces a softer part. As a result, these components can bend or stretch differently than other parts of the 4-D structure around them.

The printer can even create electrical wiring that can be printed directly onto an antenna, sensor or other electrical device. The process relies on a direct-ink-write method to produce a line of silver nanoparticle ink. A photonic cure unit dries and coalesces the nanoparticles to form conductive wire. Then, the printer’s ink-jet component creates the plastic coating that encases the wire.

Currently, Qi’s team is also working with Children’s Healthcare of Atlanta to determine whether this new technology could print prosthetic hands for children born with malformed arms.

“Only a small group of children have this condition, so there isn’t a lot of commercial interest in it and most insurance does not cover the expense,” Qi says. “But these children have a lot of challenges in their daily lives, and we hope our new 4-D printer will help them overcome some of these difficulties.”

Qi acknowledges funding from the National Science Foundation, the U.S. Air Force Office of Scientific Research, HP Inc. and Northrop Grumman.

####

About American Chemical Society

The American Chemical Society, the world’s largest scientific society, is a not-for-profit organization chartered by the U.S. Congress. ACS is a global leader in providing access to chemistry-related information and research through its multiple databases, peer-reviewed journals and scientific conferences. ACS does not conduct research, but publishes and publicizes peer-reviewed scientific studies. Its main offices are in Washington, D.C., and Columbus, Ohio.

For more information, please click here

Contacts:

ACS National Meeting Press Center, March 18-21

504-670-6721

Katie Cottingham, Ph.D.

301-775-8455

Copyright © American Chemical Society

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Chemistry

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Events/Classes

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

![]() A New Blue: Mysterious origin of the ribbontail ray’s electric blue spots revealed July 5th, 2024

A New Blue: Mysterious origin of the ribbontail ray’s electric blue spots revealed July 5th, 2024

![]() Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Researchers demonstrate co-propagation of quantum and classical signals: Study shows that quantum encryption can be implemented in existing fiber networks January 20th, 2023

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||