Home > Press > Thinking thin brings new layering and thermal abilities to the semiconductor industry: In a breakthrough for the semiconductor industry, researchers demonstrate a new layer transfer technique called "controlled spalling" that creates many thin layers from a single gallium nitride

|

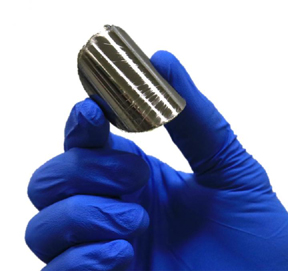

| The same 20-micron spalled GaN film, demonstrating the film's flexibility. CREDIT Bedell/IBM Research |

Abstract:

What would a simple technique to remove thin layers from otherwise thick, rigid semiconductor crystals mean for the semiconductor industry? This concept has been actively explored for years, as integrated circuits made on thin layers hold promise for developments including improved thermal characteristics, lightweight stackability and a high degree of flexibility compared to conventionally thick substrates.

Thinking thin brings new layering and thermal abilities to the semiconductor industry: In a breakthrough for the semiconductor industry, researchers demonstrate a new layer transfer technique called "controlled spalling" that creates many thin layers from a single gallium nitride

Washington, DC | Posted on July 11th, 2017In a significant advance, a research group from IBM successfully applied their new "controlled spalling" layer transfer technique to gallium nitride (GaN) crystals, a prevalent semiconductor material, and created a pathway for producing many layers from a single substrate.

As they report in the Journal of Applied Physics, from AIP Publishing, controlled spalling can be used to produce thin layers from thick GaN crystals without causing crystalline damage. The technique also makes it possible to measure basic physical properties of the material system, like strain-induced optical effects and fracture toughness, which are otherwise difficult to measure.

Single-crystal GaN wafers are extremely expensive, where just one 2-inch wafer can cost thousands of dollars, so having more layers means getting more value out of each wafer. Thinner layers also provide performance advantages for power electronics, since it offers lower electrical resistance and heat is easier to remove.

"Our approach to thin film removal is intriguing because it's based on fracture," said Stephen W. Bedell, research staff member at IBM Research and one of the paper's authors. "First, we first deposit a nickel layer onto the surface of the material we want to remove. This nickel layer is under tensile strength -- think drumhead. Then we simply roll a layer of tape onto the nickel, hold the substrate down so it can't move, and then peel the tape off. When we do this, the stressed nickel layer creates a crack in the underlying material that goes down into the substrate and then travels parallel to the surface."

Their method boils down to simply peeling off the tape, nickel layer and a thin layer of the substrate material stuck to the nickel.

"A good analogy of how remarkable this process is can be made with a pane of glass," Bedell said. "We're breaking the glass in the long direction, so instead of a bunch of broken glass shards, we're left with two full sheets of glass. We can control how much of the surface is removed by adjusting the thickness of the nickel layer. Because the entire process is done at room temperature, we can even do this on finished circuits and devices, rendering them flexible."

The group's work is noteworthy for multiple reasons. For starters, it's by far the simplest method of transferring thin layers from thick substrates. And it may well be the only layer transfer method that's materially agnostic.

"We've already demonstrated the transfer of silicon, germanium, gallium arsenide, gallium nitride/sapphire, and even amorphous materials like glass, and it can be applied at nearly any time in the fabrication flow, from starting materials to partially or fully finished circuits," Bedell said.

Turning a parlor trick into a reliable process, working to ensure that this approach would be a consistent technique for crack-free transfer, led to surprises along the way.

"The basic mechanism of substrate spalling fracture started out as a materials science problem," he said. "It was known that metallic film deposition would often lead to cracking of the underlying substrate, which is considered a bad thing. But we found that this was a metastable phenomenon, meaning that we could deposit a thick enough layer to crack the substrate, but thin enough so that it didn't crack on its own -- it just needed a crack to get started."

Their next discovery was how to make the crack initiation consistent and reliable. While there are many ways to generate a crack -- laser, chemical etching, thermal, mechanical, etc. -- it turns out that the simplest way, according to Bedell, is to terminate the thickness of the nickel layer very abruptly near the edge of the substrate.

"This creates a large stress discontinuity at the edge of the nickel film so that once the tape is applied, a small pull on the tape consistently initiates the crack in that region," he said.

Though it may not be obvious, gallium nitride is a vital material to our everyday lives. It's the underlying material used to fabricate blue, and now white, LEDs (for which the 2014 Nobel Prize in physics was awarded) as well as for high-power, high-voltage electronics. It may also prove useful for inherent biocompatibility, which when combined with control spalling may permit ultrathin bioelectronics or implantable sensors.

"Controlled spalling has already been used to create extremely lightweight, high-efficiency GaAs-based solar cells for aerospace applications and flexible state-of-the-art circuits," Bedell said.

The group is now working with research partners to fabricate high-voltage GaN devices using this approach. "We've also had great interaction with many of the GaN technology leaders through the Department of Energy's ARPA-E SWITCHES program and hope to use controlled spalling to enable novel devices through future partnerships," Bedell said.

####

About American Institute of Physics

The Journal of Applied Physics is an influential international journal publishing significant new experimental and theoretical results of applied physics research. See http://jap.aip.org .

For more information, please click here

Contacts:

Julia Majors

301-209-3090

Copyright © American Institute of Physics

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

Understanding the mechanism of non-uniform formation of diamond film on tools: Paving the way to a dry process with less environmental impact March 24th, 2023

![]() New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

New study introduces the best graphite films: The work by Distinguished Professor Feng Ding at UNIST has been published in the October 2022 issue of Nature Nanotechnology November 4th, 2022

![]() Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

Thin-film, high-frequency antenna array offers new flexibility for wireless communications November 5th, 2021

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Hardware

![]() The present and future of computing get a boost from new research July 21st, 2023

The present and future of computing get a boost from new research July 21st, 2023

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Nanoelectronics

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||