Home > Press > CRMGroup in Belgium uses a Deben three point bending stage in the development of new steel & coated steel products for automotive and other industrial applications

|

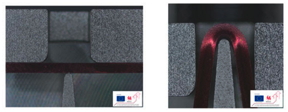

| The Deben 3-point bending stage developed with CRMGroup for metals testing. The image shows the side view of the bending micromachine. Left image) no deformation, the sample is flat. Right image) the sample has been bent by the jaws pushing down so the point of interest of the sample does not move . |

Abstract:

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on how the Center for Research in Metallurgy (CRMGroup) in Belgium is using a three point bending stage in their development program to produce new steel and coated steel products for the automotive and other industrial uses.

CRMGroup in Belgium uses a Deben three point bending stage in the development of new steel & coated steel products for automotive and other industrial applications

Woolpit, UK | Posted on March 21st, 2017CRMGroup has facilities in Liège and Gent in Belgium where R&D and technology solutions are offered to industrial partners working with metallic materials. The group has skilled and experienced research teams with unparalleled testing facilities covering the whole manufacture chain of metals, from raw materials to advanced steel applications, ranging in size from laboratory scale to pilot and even semi-industrial production lines.

Dr Xavier Vanden Eynde works at CRMGroup in Liège. Part of Xavier’s main goals is to improve the analytic and imaging capabilities for the support for the development of new processes, steel grades or coated products for a wide range of applications such as automotive and appliance industry. The understanding of the local mechanical behaviour during bending is an important issue to evaluate the flexibility of coating and metal bare substrate. Deben has been chosen by CRMGroup through a competitive tender and the equipment has been financially granted by the 2007-2013 FEDER programs from the EU (funding in the framework of “CLEARZINC/CLEARZINC SEM-FEG” project). CRM want to acknowledge the Walloon Region and the European Fund for Regional Development for this support.

CRMGroup in conjunction with Deben have developed a new micro-machine to investigate this bending behaviour of metal sheet. The set-up of this device is similar to a 3-point bending test but, in this case, the punch or anvil is fixed and the die moves. Using such a tool configuration, it is possible to keep the surface of the sample at the same position during the bending process and then to characterise the evolution in real time of the bend with either an optical microscope or a scanning electron microscope (SEM).

Dr Vanden Eynde describes the status of the project. “This stage is a prototype. It will be an important tool to understand the flexibility of a large variety of flat products. In one measurement we can have complete and continuous information about the flexibility. For example, this new microstage offers a high angle for bending and then, we have been able to investigate the origin of crack initiation and propagation.”

The work is at an early stage but has shown great promise. Samples investigated to date include the SEM study of changes to a steel surface as a function of bending radius. This is also referred to as the T-bend value as a function of the die position. In the images below, a sample is shown without deformation and after bending caused by the die pushing up. At each bending radius, the surface on the top of the bend is recorded and from image analysis, the number of cracks and the crack area are determined manually or through an image analysis algorithm. From this work, it is concluded that the characterisation of the bending properties of metal sheet in a one-step experiment, it is possible to determine the number of cracks and their dimension during bending. The visualisation of crack initiation and propagation will be useful for the next developments of coatings or coating strategies as well as to understand in-depth crack sensitivity and coating flexibility.

This Microtest three point bending stage designed to meet the experimental needs of CRMGroup is an excellent example of the commitment of Deben to provide one-off solutions for their users. For more details of how Deben may help customers to develop a special configuration or to obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk.

####

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.

For more information, please click here

Contacts:

Deben UK Limited

Brickfields Business Park

Old Stowmarket Road

Woolpit, Bury St Edmunds

Suffolk IP30 9QS, UK

T +44 (0)1359 244870

www.deben.co.uk

Talking Science Limited

39 de Bohun Court

Saffron Walden

Essex CB10 2BA

T +44(0)1799 521881

M +44(0)7843 012997

www.talking-science.com

Copyright © Deben

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Automotive/Transportation

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||