Home > Press > Helium 'balloons' offer new path to control complex materials

|

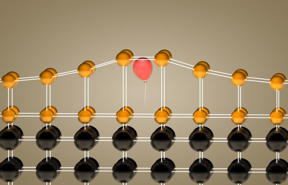

| Inserting helium atoms (visualized as a red balloon) into a crystalline film (gold) allowed Oak Ridge National Laboratory researchers to control the material's elongation in a single direction. CREDIT: ORNL |

Abstract:

Researchers at the Department of Energy's Oak Ridge National Laboratory have developed a new method to manipulate a wide range of materials and their behavior using only a handful of helium ions.

Helium 'balloons' offer new path to control complex materials

Oak Ridge, TN | Posted on June 27th, 2015The team's technique, published in Physical Review Letters, advances the understanding and use of complex oxide materials that boast unusual properties such as superconductivity and colossal magnetoresistance but are notoriously difficult to control.

For the first time, ORNL researchers have discovered a simple way to control the elongation of a crystalline material along a single direction without changing the length along the other directions or damaging the crystalline structure. This is accomplished by adding a few helium ions into a complex oxide material and provides a never before possible level of control over magnetic and electronic properties.

"By putting a little helium into the material, we're able to control strain along a single axis," said ORNL's Zac Ward, who led the team's study. "This type of control wasn't possible before, and it allows you to tune material properties with a finesse that we haven't previously had access to."

The intricate way in which electrons are bound inside complex oxides means that any strain -- stretching, pulling or pushing of the structure -- triggers changes in many different electronic properties. This ripple effect complicates scientists' ability to study or make use of the finicky materials.

The researchers demonstrated the technique on a common oxide material known as LSMO but they anticipate the technique will be widely applicable to both functionality driven materials science research and fundamental physics studies.

"Complex oxides are where we expect an immediate impact, but this technique should be an important new tool to use on any material where crystal symmetry affects functionality," Ward said.

The team's work is a step toward bringing complex materials into commercial applications, which would greatly benefit from the ability to tune material properties with processing similar to current semiconductor technologies.

"Our strain doping technique demonstrates a path to achieving this need, as it can be implemented using established ion implantation infrastructure in the semiconductor industry," Ward said.

The method uses a low-energy ion gun to add small numbers of helium ions into the material after it has been produced. The process is also reversible; the helium can be removed by heating the material to high temperatures in vacuum. Previously developed strain tuning methods modify all directions in a material and cannot be altered or reversed afterwards.

"We can easily control the amount of strain and how deep that strain is inside the material," Ward said. "By controlling the number of helium atoms inserted into an epitaxial film, we select a strain state in one direction while the other two directions are held in place by the substrate."

The team's experimental technique will also benefit theoretical research that seeks to model complex materials to predict and understand their behavior.

"The complexity of these materials requires a huge equation to explain their behaviors," Ward said. "Normal strain tuning methods require you to change many variables in that equation which means that you don't really know which one is giving you a specific reaction. In our case, there's one variable. You can feed in a single term and try to break through that complexity a little bit by simplifying it. This is a great method to experimentally probe theoretical models."

###

The paper is published as "Strain doping: Reversible single axis control of a complex oxide lattice via helium implantation." Coauthors are ORNL's Hangwen Guo, Shuai Dong, Philip Rack, John Budai, Christianne Beekman, Zheng Gai, Wolter Siemons, C.M. Gonzalez, R. Timilsina, Anthony Wong, Andreas Herklotz, Paul Snijders, Elbio Dagotto and Thomas Ward.

The study was supported by the Department of Energy's Office of Science and used resources at the Center for Nanophase Materials Sciences, a DOE Office of Science User Facility at ORNL.

####

About Oak Ridge National Laboratory

UT-Battelle manages ORNL for the Department of Energy's Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov/.

For more information, please click here

Contacts:

Morgan McCorkle

865-574-7308

Copyright © Oak Ridge National Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Superconductivity

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Laboratories

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Physics

![]() Quantum computers simulate fundamental physics: shedding light on the building blocks of nature June 6th, 2025

Quantum computers simulate fundamental physics: shedding light on the building blocks of nature June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Magnetism in new exotic material opens the way for robust quantum computers June 4th, 2025

Magnetism in new exotic material opens the way for robust quantum computers June 4th, 2025

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||