Home > Press > 'Additive manufacturing' could greatly improve diabetes management

|

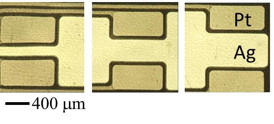

| To create new types of sensors, gold films are patterned onto a substrate using microcontract printing and etching. CREDIT: Image courtesy of Oregon State University |

Abstract:

Engineers at Oregon State University have used "additive manufacturing" to create an improved type of glucose sensor for patients with Type 1diabetes, part of a system that should work better, cost less and be more comfortable for the patient.

'Additive manufacturing' could greatly improve diabetes management

Corvallis, OR | Posted on March 17th, 2015A key advance is use of electrohydrodynamic jet, or "e-jet" printing, to make the sensor. Conceptually, e-jet printing is a little like an inexpensive inkjet printer - but it creates much finer drop sizes and works with biological materials such as enzymes, instead of ink.

The technology would create an "artificial pancreas" using a single point of bodily entry, or catheter, instead of existing systems that require four entry points, usually in a type of belt worn around the waist.

"This technology and other work that could evolve from it should improve a patient's health, comfort and diabetes management," said Greg Herman, an OSU associate professor of chemical engineering.

These systems provide constant monitoring of blood glucose concentrations and are matched with portable infusion pumps. They control delivery of the hormones insulin and glucagon, and maintain safe levels of glucose in the blood.

The findings have been reported in the ECS Journal of Solid State Science and Technology, in work supported by the National Institutes of Health.

Type 1 diabetes, which used to be called juvenile diabetes, can lead to serious health complications unless glucose levels are carefully controlled. Problems can include retinopathy, blindness, neuropathy, kidney and cardiac disease.

Researchers say that this system may ultimately prove useful with Type 2 diabetes as well, and that it has the capability of making other biological measurements, beyond just blood sugar.

Diabetes is a global, rapidly increasing health problem. In 2014, the International Diabetes Federation estimated that 387 million people around the world had some type of diabetes, and that number is expected to rise to 592 million within 20 years. The global economic cost last year was estimated at $612 billion, and the agency reported that more than three out of four people with diabetes live in low or middle-income countries.

From an engineering perspective, the new approach is more precise, less intrusive, uses fewer processing steps, avoids waste and costs less.

"These are disposable devices that only last about a week and then need to be replaced," Herman said. "Some other approaches used to make them might waste up to 90 percent of the materials being used, and that's a problem in a throw-away sensor. It's also important to keep costs as low as possible, and printing systems are inherently low-cost."

Another important advance was the use of plastic substrates, which are the same thickness as kitchen plastic wrap, so that the sensors can be wrapped around a catheter.

"The challenges of making these sensors on such thin plastic films were difficult to overcome, but we found that additive manufacturing approaches simplified the process, and should lead to much lower costs," said John Conley, an OSU professor of electrical engineering.

A patent has been applied for on the technology by OSU and Pacific Diabetes Technologies of Portland, Ore., which is working to commercialize the system. It's already being tested in animals, and there are no apparent obstacles to its development in the health marketplace, Herman said.

###

Collaborators on the research included the OSU School of Chemical, Biological and Environmental Engineering; OSU School of Electrical Engineering and Computer Science; Oregon Health & Science University; and Pacific Diabetes Technologies. Other support came from the Leona M. and Harry B. Helmsley Charitable Trust, the Oregon Nanoscience and Microtechnologies Institute, and the Juvenile Diabetes Research Foundation.

####

For more information, please click here

Contacts:

Greg Herman

541-737-2496

Copyright © Oregon State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Dental

![]() Innovations in dentistry: Navigational surgery, robotics, and nanotechnology October 2nd, 2020

Innovations in dentistry: Navigational surgery, robotics, and nanotechnology October 2nd, 2020

![]() First measurement of electron energy distributions, could enable sustainable energy technologies June 5th, 2020

First measurement of electron energy distributions, could enable sustainable energy technologies June 5th, 2020

![]() Gas storage method could help next-generation clean energy vehicles: Tremendous amounts of hydrogen and methane can be stored in nanoscopic pores April 17th, 2020

Gas storage method could help next-generation clean energy vehicles: Tremendous amounts of hydrogen and methane can be stored in nanoscopic pores April 17th, 2020

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||