Home > Press > An ultrasensitive molybdenum-based image sensor: New material can result in 5 times more sensitive cameras

|

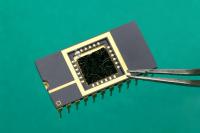

| This prototype is the first ever molybdenum based image sensor, 5 times more sensitive than current silicium-based technology

Credit: EPFL / Alain Herzog |

Abstract:

A new material has the potential to improve the sensitivity of photographic image sensors by a factor of five. In 2011, an EPFL team led by Andras Kis discovered the amazing semi-conducting properties of molybdenite (MoS2), and they have been exploring its potential in various technological applications ever since. This promising candidate for replacing silicon has now been integrated in a prototype of an image sensor. This sensor, described in an article appearing in Nature Nanotechnology, has five times the light sensitivity of current technology.

An ultrasensitive molybdenum-based image sensor: New material can result in 5 times more sensitive cameras

Lausanne, Switzerland | Posted on June 12th, 2013All digital cameras work according to the same principle: they convert light into an electric charge. The camera has a light sensor, whose surface is a semi-conducting material that is divided into millions of cells, or pixels. The semi-conducting material on each cell reacts to the incoming light by generating a specific electrical charge, which is then transferred to the camera's firmware for processing. The efficiency of this process depends on the quantity of light that is needed to trigger the charge transfer.

The all-time pixel record

The objective of the EPFL researchers was to demonstrate molybdenite's potential in image sensors. For this reason, their sensor only has a single pixel. But it needs five times less light to trigger a charge transfer than the silicon-based sensors that are currently available. "Our main goal is to prove that MoS2 is an ideal candidate for this kind of application," explains Kis.

This level of sensitivity would open up the huge area of low-light or night photography, without resorting to "noise"-generating amplification techniques, slowing down the shutter speed or using a flash. For some specialized domains in which light conditions are often not optimal, such as astrophotography or biological imaging, the advantage is even more obvious. "It would make it possible to take photographs using only starlight," says Kis.

A revolutionary material

Molybdenite's extraordinary properties make this performance possible. Like the silicon used in currently available sensors, molybdenite requires an electric current, which comes from the battery. To generate a pixel, the charge generated by the light energy must be greater than the threshold current from the battery.

A single-atom layer of molybdenite requires only a very small electric charge to function. Because of this, it takes much less light energy to reach the threshold needed to generate a pixel. MoS2 is a naturally abundant, inexpensive material. In addition, Kis explains, the prototype doesn't require any other semi-conductors, which should greatly simplify manufacturing processes. Kis, who is a pioneer in research on the semi-conductivity of molybdenite, recently demonstrated its potential in an integrated circuit and, in early 2013, a flash memory prototoype. With this new step into imaging, molybdenite shows its extraordinary potential in another important area of application.

####

For more information, please click here

Contacts:

Lionel Pousaz

41-795-597-161

Copyright © Ecole Polytechnique Fédérale de Lausanne

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Imaging

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||