Home > Press > Insects Inspire X-ray Improvements: Nanostructures Modeled After Moth Eyes May Enhance Medical Imaging

|

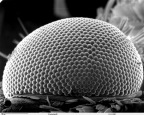

| Scanning electron microscope image of the eye on a leaf miner moth. (Photo: Dartmouth College) |

Abstract:

Using the compound eyes of the humble moth as their inspiration, an international team of physicists has developed new nanoscale materials that could someday reduce the radiation dosages received by patients getting X-rayed, while improving the resolution of the resulting images.

Insects Inspire X-ray Improvements: Nanostructures Modeled After Moth Eyes May Enhance Medical Imaging

Washington, DC | Posted on July 4th, 2012The work, led by Yasha Yi—a professor of the City University of New York, who is also affiliated with Massachusetts Institute of Technology and New York University—was published today in the Optical Society's (OSA) journal, Optics Letters.

Like their Lepidopteran cousins the butterflies, moths have large compound eyes, made up of many thousands of ommatidia—structures made up of a primitive cornea and lens, connected to photoreceptor cells. But moth eyes, unlike those of butterflies, are remarkably anti-reflective, bouncing back very little of the light that strikes them. The adaptation helps the insects be stealthier and less visible to predators during their nocturnal flights. Because of this feature, engineers have looked to the moth eye to help design more efficient coatings for solar panels and antireflective surfaces for military devices, among other applications.

Now Yi and his colleagues have gone a step further, using the moth eye as a model for a new class of materials that improve the light-capturing efficiency of X-ray machines and similar medical imaging devices.

In particular, the researchers focused on so-called "scintillation" materials: compounds that, when struck by incoming particles (say, X-ray photons), absorb the energy of the particles and then reemit that absorbed energy in the form of light. In radiographic imaging devices, such scintillators are used to convert the X-rays exiting the body into the visible light signals picked up by a detector to form an image.

One way to improve the output (the intensity of light signals read by the detector, and thus the resolution of the resulting images) is to increase the input—that is, to use a higher x-ray dosage. But that's not healthy for patients because of the increased levels of radiation. An alternative, Yi and colleagues figured, is to improve the efficiency with which the scintillator converts X-rays to light. Their new material does just that.

It consists of a thin film, just 500 nanometers thick, made of a special type of crystal known as cerium-doped lutetium oxyorthosilicate. These crystals were encrusted with tiny pyramid-shaped bumps or protuberances made of the ceramic material silicon nitride. Each protuberance, or "corneal nipple," is modeled after the structures in a moth's eye and is designed to extract more light from the film.

Between 100,000 to 200,000 of the protuberances fit within a 100 x 100 micrometer square, or about the same density as in an actual moth eye. The researchers then made the sidewalls of the device rougher, improving its ability to scatter light and thus enhancing the efficiency of the scintillator.

In lab experiments, Yi and colleagues found that adding the thin film to the scintillator of an X-ray mammographic unit increased the intensity of the emitted light by as much as 175 percent compared to that produced using a traditional scintillator.

The current work, Yi says, represents a proof-of-concept evaluation of the use of the moth-eye-based nanostructures in medical imaging materials. "The moth eye has been considered one of the most exciting bio structures because of its unique nano-optical properties," he says, "and our work further improved upon this fascinating structure and demonstrated its use in medical imaging materials, where it promises to achieve lower patient radiation doses, higher-resolution imaging of human organs, and even smaller-scale medical imaging. And because the film is on the scintillator," he adds, "the patient would not be aware of it at all."

Yi estimates that it will take at least another three to five years to evaluate and perfect the film, and test it in imaging devices. "We will need to work with medical imaging experts and radiologists for this to be actually used in clinical practice," he says.

The work was done in collaboration with Professors Bo Liu and Hong Chen of Tongji University in Shanghai.

Paper: "Giant light extraction enhancement of medical imaging scintillation materials using biologically inspired integrated nanostructures," Optics Letters, Vol. 37, Issue 14, pp. 2808-2810 (2012).

EDITOR'S NOTE: Supporting images are available to members of the media upon request. Contact Angela Stark at

####

About Optical Society of America

Uniting more than 130,000 professionals from 175 countries, the Optical Society (OSA) brings together the global optics community through its programs and initiatives. Since 1916 OSA has worked to advance the common interests of the field, providing educational resources to the scientists, engineers and business leaders who work in the field by promoting the science of light and the advanced technologies made possible by optics and photonics. OSA publications, events, technical groups and programs foster optics knowledge and scientific collaboration among all those with an interest in optics and photonics.

About Optics Letters

Published by the Optical Society (OSA), Optics Letters offers rapid dissemination of new results in all areas of optics with short, original, peer-reviewed communications. Optics Letters covers the latest research in optical science, including optical measurements, optical components and devices, atmospheric optics, biomedical optics, Fourier optics, integrated optics, optical processing, optoelectronics, lasers, nonlinear optics, optical storage and holography, optical coherence, polarization, quantum electronics, ultrafast optical phenomena, photonic crystals, and fiber optics. This journal, edited by Alan E. Willner of the University of Southern California and published twice each month, is where readers look for the latest discoveries in optics. Visit www.OpticsInfoBase.org/OL.

For more information, please click here

Contacts:

The Optical Society

Angela Stark

202-416-1443

Copyright © Business Wire

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Imaging

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||