Home > Press > Imec reports breakthrough in narrow pitch interconnects

|

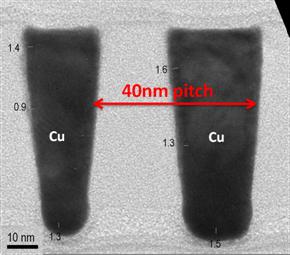

| Cross sectional TEM analysis of 20nm ½ pitch interconnects after integration into single damascene using a spacer defined double patterning approach |

Abstract:

Imec sets major step towards 20nm half pitch interconnects with the realization of electrically functional copper lines embedded into silicon oxide using a spacer-defined double patterning approach.

Imec reports breakthrough in narrow pitch interconnects

Leuven, Belgium | Posted on July 14th, 2010"We are very proud to be the world's first in developing and processing such small on-pitch working interconnects;" said Zsolt Tokei, program director interconnects at imec. "Spacer-defined (or self-aligned) double patterning has recently gained interest as the patterning technique for future FLASH memory devices. I'm confident that memory companies will benefit from this state-of-the-art result."

Scaling of interconnects towards 20nm half pitch faces many challenges. Double patterning lithography is needed since the metal lines cannot be realized in a single print. Therefore, a solution is needed for the actual design split of the structures and the alignment of the different masks. And, filling of (sub-)20nm lines is not possible using standard physical vapor deposition of TaN/Ta-based metallization. Moreover, control of line-edge roughness becomes increasingly difficult with further scaling. And finally, engineering of the patterning stack is required for optimal adhesion.

Imec demonstrated patterning and metallization of 20nm half pitch copper lines in silicon oxide with a TiN metal hard mask. The patterning is based on a sacrificial double hard mask and uses 3 photos (CORE, TRIM and PATCH) and four etch steps. The CORE photo defines dense lines at 40nm half pitch, which after trim, etch and spacer deposition results in 20nm half pitch spacer loops. The TRIM makes large openings to cut the spacer loops away by etch. And PATCH defines the final layout, electrical connections and bond pads. Overlay control is critical in order to end up with the designed test pattern. The dielectric spacing between the metal lines was accurately controlled thanks to the spacer-defined integration method. A Ruthenium-based metallization scheme was used to realize void-less filling.

Dielectric breakdown properties of the interconnects were measured and the results are very encouraging as the breakdown field is close to the intrinsic dielectric breakdown properties of the oxide and dielectric cap layers.

These results were obtained in cooperation with imec's key partners in its core CMOS programs: Intel, Micron, Panasonic, Samsung, TSMC, Sony, Fujitsu, Infineon, Qualcomm, ST Microelectronic, Amkor.

####

About imec

Imec performs world-leading research in nanoelectronics. Imec leverages its scientific knowledge with the innovative power of its global partnerships in ICT, healthcare and energy. Imec delivers industry-relevant technology solutions. In a unique high-tech environment, its international top talent is committed to providing the building blocks for a better life in a sustainable society. Imec is headquartered in Leuven, Belgium, and has offices in Belgium, the Netherlands, Taiwan, US, China and Japan. Its staff of more than 1,750 people includes over 550 industrial residents and guest researchers. In 2009, imec's revenue (P&L) was 275 million euro. Further information on imec can be found at www.imec.be.

NOTE: Imec is a registered trademark for the activities of IMEC International (a legal entity set up under Belgian law as a "stichting van openbaar nut”), imec Belgium (IMEC vzw supported by the Flemish Government), imec the Netherlands (Stichting IMEC Nederland, part of Holst Centre which is supported by the Dutch Government), imec Taiwan (IMEC Taiwan Co.) and imec China (IMEC Microelectronics (Shangai) Co. Ltd.).

For more information, please click here

Contacts:

imec: Katrien Marent, Director, External Communications, T: +32 16 28 18 80, M: +32 474 30 28 66,

Barbara Kalkis, Maestro Marketing & PR, T: +1 408 996 9975, M: +1 408 529 4210,

Copyright © imec

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Chip Technology

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

Beyond silicon: Electronics at the scale of a single molecule January 30th, 2026

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Memory Technology

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Utilizing palladium for addressing contact issues of buried oxide thin film transistors April 5th, 2024

Nanoelectronics

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

Interdisciplinary: Rice team tackles the future of semiconductors Multiferroics could be the key to ultralow-energy computing October 6th, 2023

![]() Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

Key element for a scalable quantum computer: Physicists from Forschungszentrum Jülich and RWTH Aachen University demonstrate electron transport on a quantum chip September 23rd, 2022

![]() Reduced power consumption in semiconductor devices September 23rd, 2022

Reduced power consumption in semiconductor devices September 23rd, 2022

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||