Home > Press > Minimizing Exposures & Improving Nano-particle Production

|

Abstract:

Introduction

The manufacture of nano-scale materials presents unique challenges for researchers, managers and safety professionals. Though many manufacturing processes and procedures may remain the same the hazards encountered are increased with the introduction of nano-particles whose dangers are not fully understood. Development of nano-materials requires a higher level of user and environmental protection, but it is widely believed that the risk from these unknown hazards can be reduced through the use of good laboratory practices and engineering controls designed to minimize worker and environmental exposure.

Minimizing Exposures & Improving Nano-particle Production

Columbus, OH | Posted on May 1st, 2007Improved Safety through Containment

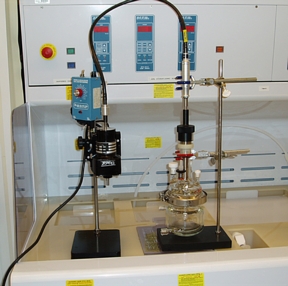

Material containment is a key factor in protecting users and the environment from accidental exposures. When mounted to standard laboratory vessels the Delp Mixer efficiently seals for varying conditions such as moderate pressure or deep vacuum; allowing the fully contained mixing of nano-particles and blended materials. The mixer is designed to integrate with established products such as explosion-proof motors and clean room equipment, thus maximizing the Health, Safety & Environmental advantages of established controls and increasing the benefits to the user and the surrounding environment.

Safer Equipment

When working with nano-materials safety is increased when separation between the user and the materials can be maximized. Barriers such as gloves, protective clothing and standard PPE for hazardous materials are believed to be effective first steps in ur protection. However these can be compromised when handing laboratory equipment such as vessels, mixers, or system mounting structures that might damage gloves or other protective clothing. Delp Mixers are designed to be easy to use, assemble and maintain, can be handled safely even in clean-room garments, and require no assembly tools which might perforate gloves and allow user contact with nano-particles.

Case Study - Columbus NanoWorks

The molecular analysis of DNA, RNA, and protein derived from diagnostic tissue specimens and/or blood samples has revolutionized pathology. Techniques such as Immunocytochemistry, Southern blot analysis, and especially the polymerase chain reaction (PCR) are an integral part of the diagnostic repertoire in pathology. However, the reliability of tests based on tissue or cell extracts often depends crucially on the relative abundance of the cell population in question, and sampling errors or a large number of „contaminating‰ cells as a result of the inherent complexity of primary tissues which can lead to false negative results. Therefore, cell separation has become increasingly commonplace for researchers and clinicians who study single cells or homogeneous cells populations to understand how cells function in different environments or to diagnose disease occurrence, recurrence, or progression.

Columbus NanoWorks (CNW) has created magnetic nanoparticles through use of Delp Mixers. CNW colloidal particles needed to be highly specific as defined by a tight standard deviation in hydrodynamic diameter, as well as having an efficient coupling process of antibodies to the surface of the particles to target cancer cells, stem cells, and other cell types. Tight control of reaction parameters within the Delp mixer allowed CNW to produce particles with a very tight size distribution, as well as coat the particles so that they retained their magnetic properties even when exposed to air. This allowed for the enrichment of 1 ovarian tumor cell in 107 total nucleated blood cells with an average recovery of 74.1% of spiked tumor samples, as well as an average 3.21 log10 depletion of contaminating cells in a flow through magnetic cell separation device. Reagents of this nature could have significant clinical impact in the early stage detection of cancers, as well as therapeutic applications in the selection of stem cells and islet cells for transplantation.

Delp Mixers have also allowed CNW to scale up their manufacturing efforts in the production of their silica particles, dextran particles, as well as ferric oxides.

Delp Mixers provide an environment which contains potential chemical hazards, and allows operation in a clean room facility.

These options help CNW to meet their customers needs.

The Gold Standard for Manufacturing

The Delp Mixers are ideal for nano-materials manufacturing and material research. Highly versatile, Delp Mixers will grow with the needs of the laboratory or manufacturing process and assist organizations in bringing their product to market faster and at a lower cost.

####

About Delp Mixer

Simple solutions. That's what you're after in the lab. Even if the problem is complex, the ideal solution should be simple.

At The Delp Mixer Company, simple solutions are what we're all about. We design, manufacture and market the most innovative laboratory mixer ever made. And at the heart of each of our revolutionary products is its utter simplicity in form and function.

Whether you're mixing materials in limited pressure or vacuum conditions, a Delp Mixer is the right tool for the job. They're scalable, user-friendly and can be assembled in minutes with just one tool. They're adaptable to most any need, and designed to use your off-the-shelf glassware. They're so durable and reliable, they're warranted for life. And, compared with the complex systems they're designed to replace, they're surprisingly affordable.

For more information, please click here

Contacts:

Lisa Delp

Phone: 614-889-1935

Copyright © Delp Mixer

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||