Home > Press > Silica 'spiky screws' could enhance industrial coatings, additive manufacturing

|

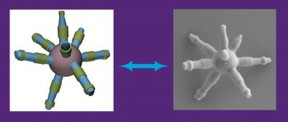

| The screw-like spikes grown from a spherical silica particle depicted above may alter the internal strength of materials used in industrial coatings, 3-D printing and other additively manufactured objects. CREDIT: ORNL |

Abstract:

It took marine sponges millions of years to perfect their spike-like structures, but research mimicking these formations may soon alter how industrial coatings and 3-D printed to additively manufactured objects are produced.

Silica 'spiky screws' could enhance industrial coatings, additive manufacturing

Oak Ridge, TN | Posted on June 24th, 2015A molecular process developed by researchers at the Department of Energy's Oak Ridge National Laboratory, paves the way for improved silica structure design by introducing microscopic, segmented screw-like spikes that can more effectively bond materials for commercial use.

The study, conducted by Jaswinder Sharma and his colleagues Panos Datskos and David Cullen, has been published in Angewandte Chemie International Edition. Authors said other applications of the screw-like spikes could include coatings for eyeglasses, television screens, commercial transportation and even self-cleaning windows and roofs in rural and urban environments.

Created by emulsion droplets applied to a silica particle's surface, the new, segmented spikes offer an alternative tool for material scientists and engineers that can better maintain and fuse bonds within a variety of microstructures.

Combined with tetraethyl orthosilicate, an additive molecule, the emulsion droplets begin to produce rod-like spikes whose growth can be controlled for silica structures and configured into new materials.

The development of a segmented spike comes as an enhanced version of previous research conducted by the team. Sharma explained that the screw-like shape of these spikes was achieved when temperature control was incorporated with the spike growth on preformed particles

In previous experiments, the spikes appeared in a rod-like, linear shape, preventing the silica from bending into the diverse shapes Sharma's team sought to create from the particle seeds.

"If you try to use these linear ones, they will lie down like a pen does," Sharma said. "They won't stand. But if you have the segmented, spiky screws or smooth spiky screws, they will stand. They are the better shape."

According to the authors, the segmented spike's most direct application rests on interface engineering and the ongoing advancements in additive manufacturing, another significant ORNL research area.

With the spikes' new shape, materials for bonding layers can maintain a stronger internal structure, lasting longer than previously used approaches.

Authors also experimented with a hybrid structure made from silica and titania, confirming that the silica-based spike growth can work for other oxide materials as well.

While they noted the hybrid's use in future processes, the authors said the spectrum of possibilities remains wide open for future researchers to explore.

"We actually developed a process to create new structures, but we didn't focus on one application when we did that," Sharma said. "We looked at a range of applications where this could fit, and we are now trying to explore all those directions."

###

Funding for this research was provided ORNL's Laboratory Directed Research and Development program.

Microscopy research was conducted as part of a user proposal at ORNL's Center for Nanophase Materials Sciences.

####

About DOE/Oak Ridge National Laboratory

ORNL is managed by UT-Battelle for the Department of Energy's Office of Science.

The Center for Nanophase Materials Sciences is one of five DOE Nanoscale Science Research Centers, national user facilities for interdisciplinary research at the nanoscale, supported by the DOE Office of Science. Together the NSRCs comprise a suite of complementary facilities that provide researchers with state-of-the-art capabilities to fabricate, process and characterize and model nanoscale materials, and constitute the largest infrastructure investment of the National Nanotechnology Initiative. The NSRCs are located at DOE's Argonne, Brookhaven, Lawrence, Berkeley, Oak Ridge, Sandia and Los Alamos national laboratories.

DOE's Office of Science is the single largest supporter of basic research in the physical sciences in the United States, and is working to address some of the most pressing challenges of our time. For more information, please visit science.energy.gov.

For more information, please click here

Contacts:

Heidi Hill

865-241-0709

Copyright © DOE/Oak Ridge National Laboratory

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Laboratories

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||