Home > Press > 'Microcombing' creates stronger, more conductive carbon nanotube films

|

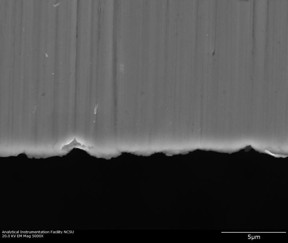

| Surgical blades appear straight to the naked eye, but they actually have micrometer-scale fissures on their cutting edge. These fissures create a kind of "microcomb" that can be used to align carbon nanotubes. CREDIT: Yuntian Zhu, North Carolina State University |

Abstract:

Researchers from North Carolina State University and China's Suzhou Institute of Nano-Science and Nano-Biotics have developed an inexpensive technique called "microcombing" to align carbon nanotubes (CNTs), which can be used to create large, pure CNT films that are stronger than any previous such films. The technique also improves the electrical conductivity that makes these films attractive for use in electronic and aerospace applications.

'Microcombing' creates stronger, more conductive carbon nanotube films

Raleigh, NC | Posted on May 5th, 2015"It's a simple process and can create a lightweight CNT film, or 'bucky paper,' that is a meter wide and twice as strong as previous such films - it's even stronger than CNT fibers," says Yuntian Zhu, Distinguished Professor of Materials Science and Engineering at NC State and corresponding author of a paper describing the work.

The researchers begin by growing the CNTs on a conventional substrate in a closely packed array. The CNTs are tangled together, so when researchers pull on one end of the array the CNTs form a continuous ribbon that is only nanometers thick. This ribbon is attached to a spool, which begins winding the ribbon up.

As the spool pulls, the CNT ribbon is dragged between two surgical blades. While the blades appear straight to the naked eye, they actually have micrometer-scale fissures on their cutting edge. These fissures create a kind of "microcomb" that pulls the CNTs into alignment - just as a regular comb sorts through tangled hair.

When the ribbon of aligned CNTs is being wound onto the spool, the researchers apply an alcohol solution. This pulls the CNTs closer together, strengthening the bonds between CNTs.

The CNT ribbon wraps around itself as it winds around the spool, creating a layered film of pure CNTs. Researchers can control the thickness of the film by controlling the number of layers.

The CNT films made using the microcombing technique had more than twice the tensile strength of the uncombed CNT films - greater than 3 gigapascals for the microcombed material, versus less than 1.5 gigapascals for the uncombed material.

The microcombed CNT film also had 80 percent higher electrical conductivity than the uncombed film.

"This is a significant advance, but we want to find ways to make CNT alignment even straighter," Zhu says. "It's still not perfect.

"In addition, the technique would theoretically be easy to scale up for large-scale production. We'd like to find an industry partner to help us scale this up and create a material for the marketplace."

####

For more information, please click here

Contacts:

Matt Shipman

919-515-6386

Copyright © North Carolina State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

Thin films

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||