Home > Press > Taking aircraft manufacturing out of the oven: New technique uses carbon nanotube film to directly heat and cure composite materials

|

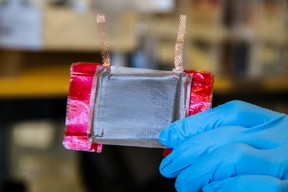

| A new film of carbon nanotubes cures composites for airplane wings and fuselages, using only 1 percent of the energy required by traditional, oven-based manufacturing processes.

Photo: Jose-Luis Olivares/MIT |

Abstract:

Composite materials used in aircraft wings and fuselages are typically manufactured in large, industrial-sized ovens: Multiple polymer layers are blasted with temperatures up to 750 degrees Fahrenheit, and solidified to form a solid, resilient material. Using this approach, considerable energy is required first to heat the oven, then the gas around it, and finally the actual composite.

Taking aircraft manufacturing out of the oven: New technique uses carbon nanotube film to directly heat and cure composite materials

Cambridge, MA | Posted on April 14th, 2015Aerospace engineers at MIT have now developed a carbon nanotube (CNT) film that can heat and solidify a composite without the need for massive ovens. When connected to an electrical power source, and wrapped over a multilayer polymer composite, the heated film stimulates the polymer to solidify.

The group tested the film on a common carbon-fiber material used in aircraft components, and found that the film created a composite as strong as that manufactured in conventional ovens -- while using only 1 percent of the energy.

The new "out-of-oven" approach may offer a more direct, energy-saving method for manufacturing virtually any industrial composite, says Brian L. Wardle, an associate professor of aeronautics and astronautics at MIT.

"Typically, if you're going to cook a fuselage for an Airbus A350 or Boeing 787, you've got about a four-story oven that's tens of millions of dollars in infrastructure that you don't need," Wardle says. "Our technique puts the heat where it is needed, in direct contact with the part being assembled. Think of it as a self-heating pizza. ... Instead of an oven, you just plug the pizza into the wall and it cooks itself."

Wardle says the carbon nanotube film is also incredibly lightweight: After it has fused the underlying polymer layers, the film itself -- a fraction of a human hair's diameter -- meshes with the composite, adding negligible weight.

The team, including MIT graduate students Jeonyoon Lee and Itai Stein and Seth Kessler of the Metis Design Corporation, has published its results in the journal ACS Applied Materials and Interfaces.

Carbon nanotube deicers

Wardle and his colleagues have experimented with CNT films in recent years, mainly for deicing airplane wings. The team recognized that in addition to their negligible weight, carbon nanotubes heat efficiently when exposed to an electric current.

The group first developed a technique to create a film of aligned carbon nanotubes composed of tiny tubes of crystalline carbon, standing upright like trees in a forest. The researchers used a rod to roll the "forest" flat, creating a dense film of aligned carbon nanotubes.

In experiments, Wardle and his team integrated the film into airplane wings via conventional, oven-based curing methods, showing that when voltage was applied, the film generated heat, preventing ice from forming.

The deicing tests inspired a question: If the CNT film could generate heat, why not use it to make the composite itself?

How hot can you go?

In initial experiments, the researchers investigated the film's potential to fuse two types of aerospace-grade composite typically used in aircraft wings and fuselages. Normally the material, composed of about 16 layers, is solidified, or cross-linked, in a high-temperature industrial oven.

The researchers manufactured a CNT film about the size of a Post-It note, and placed the film over a square of Cycom 5320-1. They connected electrodes to the film, then applied a current to heat both the film and the underlying polymer in the Cycom composite layers.

The team measured the energy required to solidify, or cross-link, the polymer and carbon fiber layers, finding that the CNT film used one-hundredth the electricity required for traditional oven-based methods to cure the composite. Both methods generated composites with similar properties, such as cross-linking density.

Wardle says the results pushed the group to test the CNT film further: As different composites require different temperatures in order to fuse, the researchers looked to see whether the CNT film could, quite literally, take the heat.

"At some point, heaters fry out," Wardle says. "They oxidize, or have different ways in which they fail. What we wanted to see was how hot could this material go."

To do this, the group tested the film's ability to generate higher and higher temperatures, and found it topped out at over 1,000 F. In comparison, some of the highest-temperature aerospace polymers require temperatures up to 750 F in order to solidify.

"We can process at those temperatures, which means there's no composite we can't process," Wardle says. "This really opens up all polymeric materials to this technology."

The team is working with industrial partners to find ways to scale up the technology to manufacture composites large enough to make airplane fuselages and wings.

"There needs to be some thought given to electroding, and how you're going to actually make the electrical contact efficiently over very large areas," Wardle says. "You'd need much less power than you are currently putting into your oven. I don't think it's a challenge, but it has to be done."

###

This research was funded in part by Airbus Group, Boeing, Embraer, Lockheed Martin, Saab AB, TohoTenax, ANSYS Inc., the Air Force Research Laboratory at Wright-Patterson Air Force Base, and the U.S. Army Research Office.

####

For more information, please click here

Contacts:

Abby Abazorius

617-253-2709

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Industrial

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Quantum interference in molecule-surface collisions February 28th, 2025

Quantum interference in molecule-surface collisions February 28th, 2025

![]() Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Boron nitride nanotube fibers get real: Rice lab creates first heat-tolerant, stable fibers from wet-spinning process June 24th, 2022

Grants/Sponsored Research/Awards/Scholarships/Gifts/Contests/Honors/Records

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

Researchers tackle the memory bottleneck stalling quantum computing October 3rd, 2025

![]() New discovery aims to improve the design of microelectronic devices September 13th, 2024

New discovery aims to improve the design of microelectronic devices September 13th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||