Home > Press > New processing technology converts packing peanuts to battery components

|

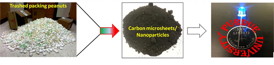

| This schematic depicts a process for converting waste packing peanuts into high-performance carbon electrodes for rechargeable lithium-ion batteries that outperform conventional graphite electrodes, representing an environmentally friendly approach to reuse the waste.

CREDIT: Purdue University image/Vinodkumar Etacheri |

Abstract:

Upcycling of Packing-Peanuts into Carbon Microsheet Anodes for Lithium-Ion Batteries

Vinodkumar Etacheri, Chulgi Nathan Hong, and Vilas G. Pol *

School of Chemical Engineering, Purdue University

*E-mail:

Environmental pollution caused by ubiquitous waste packaging materials is a serious global issue that needs to be urgently addressed. Millions of tons of plastic waste are generated worldwide every year, and it is critical to find efficient methods for their disposal and recycling. Recent studies verified that plastic containers, bags, bottles and packing peanuts constitute 31 % of the municipal waste created in the U. S. A, and only ~ 40 % of these packaging materials are recycled. Currently, only a very small fraction (~10 %) of the packing peanuts is being recycled. Due to their low density (huge containers are required for transportation), shipment to a recycler is expensive, and does not provide profit on investment. As a result, most often packing peanuts end up in landfills, where they stay intact for generations. Chemical moieties such as heavy metals, chlorides, phthalates etc. present in the packing peanuts can be easily leached into the surrounding media and deteriorate soil/water quality. We addressed the detrimental environmental impacts caused by polystyrene and starch based packing peanuts by upcycling them to carbon nanoparticles and microsheets, respectively for electrochemical energy storage, especially Li, and Na-ion batteries. State of the art synthesis of carbonaceous materials often involves the use of hydrocarbon precursors such as acetylene or coal. The method described herein does not use pressurized containers, which makes them attractive for the large-scale production of carbonaceous materials for numerous applications. Anodes composed of these microsheets and nanoparticles outperformed the electrochemical properties of commercial carbon anode in Li, and Na-ion batteries. At a current density of 0.1 C, carbon microsheet, and nanoparticle anodes exhibited Li-ion storage specific capacity of 420 mAh/g, which is even superior to the theoretical capacity of graphite (372 mAh/g). Superior electrochemical properties of the carbon electrodes are attributed to their disordered nature, and porous microstructure, which allows improved solid-state and interfacial Li, and Na-ion diffusion kinetics. The synthetic method demonstrated here is inexpensive, environmentally benign, and scalable method for the synthesis of carbonaceous materials for electrochemical energy storage.

New processing technology converts packing peanuts to battery components

West Lafayette, IN | Posted on March 22nd, 2015Researchers have shown how to convert waste packing peanuts into high-performance carbon electrodes for rechargeable lithium-ion batteries that outperform conventional graphite electrodes, representing an environmentally friendly approach to reuse the waste.

Batteries have two electrodes, called an anode and a cathode. The anodes in most of today's lithium-ion batteries are made of graphite. Lithium ions are contained in a liquid called an electrolyte, and these ions are stored in the anode during recharging. Now, researchers at Purdue University have shown how to manufacture carbon-nanoparticle and microsheet anodes from polystyrene and starch-based packing peanuts, respectively.

"We were getting a lot of packing peanuts while setting up our new lab," recalled postdoctoral research associate Vinodkumar Etacheri. "Professor Vilas Pol suggested a pathway to do something useful with these peanuts."

This simple suggestion led to a potential new eco-friendly application for the packaging waste. Research findings indicate that the new anodes can charge faster and deliver higher "specific capacity" compared to commercially available graphite anodes, Pol said.

The new findings are being presented during the 249th American Chemical Society National Meeting & Exposition in Denver on March 22-26. The work was performed by Etacheri, Pol and undergraduate chemical engineering student Chulgi Nathan Hong.

"Although packing peanuts are used worldwide as a perfect solution for shipping, they are notoriously difficult to break down, and only about 10 percent are recycled," Pol said. "Due to their low density, huge containers are required for transportation and shipment to a recycler, which is expensive and does not provide much profit on investment."

Consequently, packing peanuts often end up in landfills, where they remain intact for decades. Although the starch-based versions are more environmentally friendly than the polystyrene peanuts, they do contain chemicals and detergents that can contaminate soil and aquatic ecosystems, posing a threat to marine animals, he said.

The new method "is a very simple, straightforward approach," Pol said. "Typically, the peanuts are heated between 500 and 900 degrees Celsius in a furnace under inert atmosphere in the presence or absence of a transition metal salt catalyst."

The resulting material is then processed into the anodes.

"The process is inexpensive, environmentally benign and potentially practical for large-scale manufacturing," Etacheri said. "Microscopic and spectroscopic analyses proved the microstructures and morphologies responsible for superior electrochemical performances are preserved after many charge-discharge cycles."

Commercial anode particles are about 10 times thicker than the new anodes and have higher electrical resistance, which increase charging time.

"In our case, if we are lithiating this material during the charging of a battery it has to travel only 1 micrometer distance, so you can charge and discharge a battery faster than your commercially available material," Pol said.

Because the sheets are thin and porous, they allow better contact with the liquid electrolyte in batteries.

"These electrodes exhibited notably higher lithium-ion storage performance compared to the commercially available graphite anodes," he said.

Packing-peanut-derived carbon anodes demonstrated a maximum specific capacity of 420 mAh/g (milliamp hours per gram), which is higher than the theoretical capacity of graphite (372 mAh/g), Etacheri said.

"Long-term electrochemical performances of these carbon electrodes are very stable," he said. "We cycled it 300 times without significant capacity loss. These carbonaceous electrodes are also promising for rechargeable sodium-ion batteries. Future work will include steps to potentially improve performance by further activation to increase the surface area and pore size to improve the electrochemical performance."

###

The researchers acknowledge funding from Purdue University, the university's School of Chemical Engineering and the Kirk Endowment grant from the Birck Nanotechnology Center. On this technology, Purdue's Office of Technology Commercialization filed a U.S. patent application in 2014.

####

For more information, please click here

Contacts:

Writer:

Emil Venere

765-494-4709

Source:

Vilas G. Pol

765-494-0044

Copyright © Purdue University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Patents/IP/Tech Transfer/Licensing

![]() Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

Getting drugs across the blood-brain barrier using nanoparticles March 3rd, 2023

![]() Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

Metasurfaces control polarized light at will: New research unlocks the hidden potential of metasurfaces August 13th, 2021

![]() Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Arrowhead Pharmaceuticals Announces Closing of Agreement with Takeda November 27th, 2020

Environment

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Battery Technology/Capacitors/Generators/Piezoelectrics/Thermoelectrics/Energy storage

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||