Home > Press > Turning vapors into foam-like polymer coatings

|

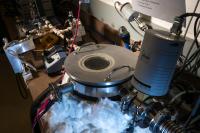

| An initiated chemical vapor deposition (ICVD) system is used to convert a mixture of gases into foam polymer.

Credit: Photo by Adam Fenster/University of Rochester. |

Abstract:

Polymers -- the essential component of plastics -- are found in countless commercial, medical, and industrial products. Polymers that are porous are called foam polymers and are especially useful because they combine light weight with rigid mechanical properties. Now a researcher at the University of Rochester has developed a process to grow highly customizable coatings of foam-like polymers.

Turning vapors into foam-like polymer coatings

Rochester, NY | Posted on October 11th, 2013The process, developed by Mitchell Anthamatten, a chemical engineer at the University's Hajim School of Engineering and Applied Science, involves growing foam polymers directly from gases. His findings were published this week in the journal Macromolecular Rapid Communications.

"With this process we can grow polymer coatings in which the density and pore structure varies in space," said Anthamatten. "My hope is that the research leads to applications in a wide variety of fields, including medical, manufacturing, and high-tech research."

Anthamatten, working closely with graduate student Ran Tao, developed a system in which a mixture of gases is pumped into a low pressure reactor containing a cold surface to encourage condensation. One of the condensed liquids actually forms the polymer material (think of the solid part of a sponge), while the other one temporarily occupies the spaces that become the pores in the foam material (think of the hollow part of a sponge). But the problem is that the liquids in the film don't mix well -- very much like water and oil. What's required is to quickly solidify the polymer film, just as the two liquids begin to separate from one another. By controlling the solidification rate, they could control the size and distribution of the pores; the faster the coating is solidified, the smaller the pores become.

Anthamatten and Tao found the answer by adjusting the rate at which the gases were fed into the system, changing the temperature of the cold surface in the reactor, and using a chemical agent that helps solidify the coating. By adjusting all those factors, they were able to coat foam polymers with different densities, thicknesses, shapes, and hole-sizes.

"This process is highly customizable, meaning that we can make adjustments along the way, shaping the material's pore structure and density as it is grown," said Anthamatten. "As a result, it will be easier to put foam polymers in hard-to-get-at places, or even on curved surfaces."

Anthamatten has worked on the project since 2008 and has received support from the National Science Foundation.

Foam polymers are used in a variety of ways, including the delivery of drugs in the body, as a framework for body tissues and implants, and as layers in laser targets for fusion research.

####

For more information, please click here

Contacts:

Peter Iglinski

585-273-4726

Copyright © University of Rochester

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Govt.-Legislation/Regulation/Funding/Policy

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

Rice membrane extracts lithium from brines with greater speed, less waste October 3rd, 2025

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() Next-generation quantum communication October 3rd, 2025

Next-generation quantum communication October 3rd, 2025

![]() "Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

"Nanoreactor" cage uses visible light for catalytic and ultra-selective cross-cycloadditions October 3rd, 2025

Tools

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

![]() Rice researchers harness gravity to create low-cost device for rapid cell analysis February 28th, 2025

Rice researchers harness gravity to create low-cost device for rapid cell analysis February 28th, 2025

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Photonics/Optics/Lasers

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||