Home > Press > Antifreeze, cheap materials may lead to low-cost solar energy

|

Abstract:

A process combining some comparatively cheap materials and the same antifreeze that keeps an automobile radiator from freezing in cold weather may be the key to making solar cells that cost less and avoid toxic compounds, while further expanding the use of solar energy.

Antifreeze, cheap materials may lead to low-cost solar energy

Corvallis, OR | Posted on July 4th, 2013 And when perfected, this approach might also cook up the solar cells in a microwave oven similar to the one in most kitchens.

Engineers at Oregon State University have determined that ethylene glycol, commonly used in antifreeze products, can be a low-cost solvent that functions well in a "continuous flow" reactor - an approach to making thin-film solar cells that is easily scaled up for mass production at industrial levels.

The research, just published in Material Letters, a professional journal, also concluded this approach will work with CZTS, or copper zinc tin sulfide, a compound of significant interest for solar cells due to its excellent optical properties and the fact these materials are cheap and environmentally benign.

"The global use of solar energy may be held back if the materials we use to produce solar cells are too expensive or require the use of toxic chemicals in production," said Greg Herman, an associate professor in the OSU School of Chemical, Biological and Environmental Engineering. "We need technologies that use abundant, inexpensive materials, preferably ones that can be mined in the U.S. This process offers that."

By contrast, many solar cells today are made with CIGS, or copper indium gallium diselenide. Indium is comparatively rare and costly, and mostly produced in China. Last year, the prices of indium and gallium used in CIGS solar cells were about 275 times higher than the zinc used in CZTS cells.

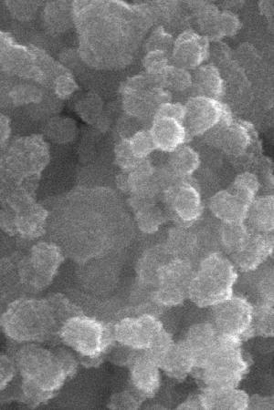

The technology being developed at OSU uses ethylene glycol in meso-fluidic reactors that can offer precise control of temperature, reaction time, and mass transport to yield better crystalline quality and high uniformity of the nanoparticles that comprise the solar cell - all factors which improve quality control and performance.

This approach is also faster - many companies still use "batch mode" synthesis to produce CIGS nanoparticles, a process that can ultimately take up to a full day, compared to about half an hour with a continuous flow reactor. The additional speed of such reactors will further reduce final costs.

"For large-scale industrial production, all of these factors - cost of materials, speed, quality control - can translate into money," Herman said. "The approach we're using should provide high-quality solar cells at a lower cost."

The performance of CZTS cells right now is lower than that of CIGS, researchers say, but with further research on the use of dopants and additional optimization it should be possible to create solar cell efficiency that is comparable.

This project is one result of work through the Center for Sustainable Materials Chemistry, a collaborative effort of OSU and five other academic institutions, supported by the National Science Foundation. Funding was provided by Sharp Laboratories of America. The goal is to develop materials and products that are safe, affordable and avoid the use of toxic chemicals or expensive compounds.

####

About Oregon State University

Oregon State is committed to innovation that leads to new businesses, jobs and economic growth for Oregon and the nation. That commitment now includes the Venture Accelerator, to move promising ideas out of the laboratory and into the marketplace; and the Industry Partnering Program, which helps improve the success of existing business and industry.

This research was supported in part by National Science Foundation grant number CHE-1102637.

About the OSU College of Engineering

The OSU College of Engineering is among the nationšs largest and most productive engineering programs. Since 1999, the college has more than tripled its research expenditures to $37.2 million by emphasizing highly collaborative research that solves global problems, spins out new companies, and produces opportunity for students through hands-on learning.

For more information, please click here

Contacts:

By David Stauth

541-737-0787

Contact: Greg Herman

541-737-2496

Copyright © Oregon State University

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||