Home > Press > New Nanotech Technique for Lower-Cost Materials Repair

|

| Todd Emrick, UMass Amherst

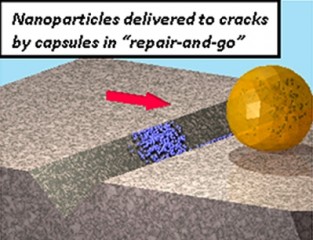

A recent materials repair discovery validates prior theory and may lead to significant conservation of material in diagnosing and repairing structural damage. The cartoon illustrates how nanoparticle-containing capsules roll or glide over damaged substrates, selectively depositing their nanoparticle contents into fractures. |

Abstract:

In the super-small world of nanostructures, a team of polymer scientists and engineers at the University of Massachusetts Amherst have discovered how to make nano-scale repairs to a damaged surface equivalent to spot-filling a scratched car fender rather than re-surfacing the entire part. The work builds on a theoretical prediction by chemical engineer and co-author Anna Balazs at the University of Pittsburgh.

New Nanotech Technique for Lower-Cost Materials Repair

Amherst, MA | Posted on January 13th, 2012Their discovery is reported this week in the current issue of Nature Nanotechnology. The new technique has many practical implications, especially that repairing a damaged surface with this method would require significantly smaller amounts of material, avoiding the need to coat entire surfaces when only a tiny fraction is cracked, says team leader and UMass Amherst polymer scientist Todd Emrick.

"This is particularly important because even small fractures can then lead to structural failure but our technique provides a strong and effective repair. The need for rapid, efficient coating and repair mechanisms is pervasive today in everything from airplane wings to microelectronic materials to biological implant devices," he adds.

At nano-scale, damaged areas typically possess characteristics quite distinct from their undamaged surrounding surface, including different topography, wetting characteristics, roughness and even chemical functionality, Emrick explains. He adds, "Anna Balazs predicted, using computer simulation, that if nanoparticles were held in a certain type of microcapsule, they would probe a surface and release nanoparticles into certain specific regions of that surface," effectively allowing a spot-repair.

This vision of capsules probing and releasing their contents in a smart, triggered fashion, known as "repair-and-go," is characteristic of biological process, such as in white blood cells, Emrick adds.

He says the experimental work to support the concept required insight into the chemistry, physics and mechanical aspects of materials encapsulation and controlled release, and was achieved by collaboration among three polymer materials laboratories at UMass Amherst, led by Alfred Crosby, Thomas Russell and himself.

The researchers show how using a polymer surfactant stabilizes oil droplets in water (in emulsion droplets or capsules), encapsulating nanoparticles efficiently, but in a manner where they can be released when desired, since the capsule wall is very thin.

"We then found that the nanoparticle-containing capsules roll or glide over damaged substrates, and very selectively deposit their nanoparticle contents into the damaged (cracked) regions. Because the nanoparticles we use are fluorescent, their localization in the cracked regions is clearly evident, as is the selectivity of their localization."

Using rapid and selective deposition of sensor material in damaged regions, their innovative work also provides a precise method for detecting damaged substrates, he stresses. Finally, the new encapsulation techniques allow delivery of hydrophobic objects in a water-based system, further precluding the need for organic solvents in industrial processes that are dis-advantageous from an environmental standpoint.

Emrick says, "Having realized the concept experimentally, looking forward we now hope to demonstrate recovery of mechanical properties of coated objects by adjusting the composition of the nanoparticles being delivered."

The work was supported by the National Science Foundations' (NSF) Materials Research Science and Engineering Center on Polymers at UMass Amherst, an NSF Integrative Graduate Education and Research Traineeship (IGERT) award, the NSF Center for Hierarchical Manufacturing, the U.S. Department of Energy and its Office of Basic Energy Science.

####

For more information, please click here

Contacts:

Todd Emrick

413/577-1613

Copyright © Newswise

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Nanomedicine

![]() New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

New molecular technology targets tumors and simultaneously silences two ‘undruggable’ cancer genes August 8th, 2025

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

Cambridge chemists discover simple way to build bigger molecules – one carbon at a time June 6th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Sensors

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||