Home > Press > Counting Graphene Sheets Spread over a Large Area

|

Abstract:

A simple way to identify the number of graphene sheets on a substrate, even over a large area, is shown by US researchers.

Counting Graphene Sheets Spread over a Large Area

Riverside, CA | Posted on August 11th, 2011Graphene is the much-loved material of-the-moment; the most recent Nobel Prize for physics was awarded to Andre Geim and Kostya Novoselov for work in this area and many researchers are following in their footsteps to investigate the exciting electric, optical, and mechanical properties of graphene. But even just identifying that you have produced a graphene sheet, and how many you have made, can be tricky.

Industrial production of graphene is usually by chemical vapor deposition (CVD) rather than by the mechanical exfoliation method (tearing off sheets from a block of graphite) much used in early work. CVD-grown sheets can be relatively very large, which is good for many industrial applications, but this method does induce some defects and wrinkles which can be hard to spot, as well as producing multiple layers of sheets. Raman and atomic force microscopy can be used to count sheets on silica or silicon but these techniques call for calibration and can only cover a small area at a time; this is not ideal for the large areas of graphene produced by CVD. As its uses expand, graphene is being made and used on a variety of substrates so it would be useful to have a method of counting that is not confined to use on only a small number of surfaces.

Advertisement

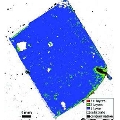

Researchers at University of California, Riverside, USA, led by Cengiz Ozkan and Mihrimah Ozkan have developed a method for quick and easy identification of layer thickness and uniformity of entire large-area graphene sheets on arbitrary substrates. They exploit the fact that graphene quenches fluorescence whereas most substrates do not, and coat an area of graphene on a surface with a fluorescent polymer dye to allow visualization with a simple fluorescence microscope. Straightforward data processing of this input identifies not only the presence but also the number of layers of graphene present in any one area. Uniformity of the sample and defects can also be assessed by this route.

The scientists went on to test their method by looking at different ways of transferring graphene from one substrate to another, and the resulting quality of the final sheets. They were able to tell the most effective method used to transfer graphene and preserve sheet quality.

Because this method is so simple, reproducible, and applicable to large areas of graphene, the authors expect it to be quickly taken up by industrial manufacturers and users of graphene, who may use it to make anything from solar cells to thermal heat sinks.

####

For more information, please click here

Copyright © John Wiley & Sons

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() J. R. Kyle et al., Small, ; DOI: 10.1002/smll.201100263

J. R. Kyle et al., Small, ; DOI: 10.1002/smll.201100263

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||