Home > Press > Vascular composites enable dynamic structural materials

|

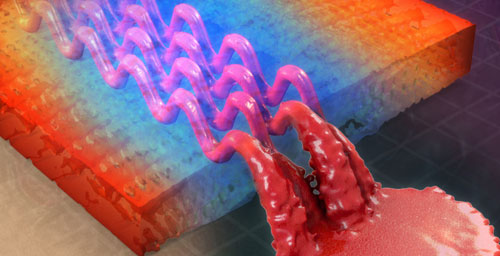

| Image by Piyush Thakre, Alex Jerez, Ryan Durdle and Jeremy Miller, Beckman Institute, U. of I.

A vascularized fiber-reinforced composite material. Illinois researchers developed a class of sacrificial fibers that degrade after composite fabrication, leaving hollow vascular tunnels that can transport liquids or gases through the composite. |

Abstract:

Taking their cue from biological circulatory systems, University of Illinois researchers have developed vascularized structural composites, creating materials that are lightweight and strong with potential for self-healing, self-cooling, metamaterials and more.

Vascular composites enable dynamic structural materials

Champaign, IL | Posted on July 25th, 2011"We can make a material now that's truly multifunctional by simply circulating fluids that do different things within the same material system," said Scott White, the Willet Professor of aerospace engineering who led the group. "We have a vascularized structural material that can do almost anything."

Composite materials are a combination of two or more materials that harness the properties of both. Composites are valued as structural materials because they can be lightweight and strong. Many composites are fiber-reinforced, made of a network of woven fibers embedded in resin - for example, graphite, fiberglass or Kevlar.

The Illinois team, part of the Autonomous Materials Systems Laboratory in the Beckman Institute for Advanced Science and Technology, developed a method of making fiber-reinforced composites with tiny channels for liquid or gas transport. The channels could wind through the material in one long line or branch out to form a network of capillaries, much like the vascular network in a tree.

"Trees are incredible structural materials, but they're dynamic too," said co-author Jeffrey Moore, the Murchison-Mallory professor of chemistry and a professor of materials science and engineering. "They can pump fluids, transfer mass and energy from the roots to the leaves. This is the first step to making synthetic materials that have that kind of functionality."

The key to the method, published in the journal Advanced Materials, is the use of sacrificial fibers. The team treated commercially available fibers so that they would degrade at high temperatures. The sacrificial fibers are no different from normal fibers during weaving and composite fabrication. But when the temperature is raised further, the treated fibers vaporize - leaving tiny channels in their place - without affecting the structural composite material itself.

"There have been vascular materials fabricated previously, including things that we've done, but this paper demonstrated that you can approach the manufacturing with a concept that is vastly superior in terms of scalability and commercial viability," White said.

In the paper, the researchers demonstrate four classes of application by circulating different fluids through a vascular composite: temperature regulation, chemistry, conductivity and electromagnetism. They regulate temperature by circulating coolant or a hot fluid. To demonstrate a chemical reaction, they injected chemicals into different vascular branches that merged, mixing the chemicals to produce a luminescent reaction. They made the structure electrically active by using conductive liquid, and changed its electromagnetic signature with ferrofluids - a key property for stealth applications.

Next, the researchers hope to develop interconnected networks with membranes between neighboring channels to control transport between channels. Such networks would enable many chemical and energy applications, such as self-healing polymers or fuel cells.

"This is not just another microfluidic device," said co-author Nancy Sottos, the Willett professor of materials science and engineering and a professor of aerospace engineering. "It's not just a widget on a chip. It's a structural material that's capable of many functions that mimic biological systems. That's a big jump."

This work was supported by the Air Force Office of Scientific Research.

####

For more information, please click here

Contacts:

Scott White

217-333-1077

Copyright © University of Illinois

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() The paper, “Three-Dimensional Microvascular Fiber-Reinforced Composites,” is available online.

The paper, “Three-Dimensional Microvascular Fiber-Reinforced Composites,” is available online.

| Related News Press |

Microfluidics/Nanofluidics

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Fuel Cells

![]() Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

Deciphering local microstrain-induced optimization of asymmetric Fe single atomic sites for efficient oxygen reduction August 8th, 2025

![]() Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

Current and Future Developments in Nanomaterials and Carbon Nanotubes: Applications of Nanomaterials in Energy Storage and Electronics October 28th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||