Home > Press > Tiny robots get a grip on nanotubes

|

Abstract:

How do you handle the tiny components needed for constructing nanoscale devices? A European consortium has built two microrobotic demonstrators that can automatically pick up and install carbon nanotubes thousands of times thinner than a human hair.

Carbon nanotubes, rolled up sheets of carbon only a few tens of nanometres in diameter, could become an essential part of the nanotechnologist's construction kit. But there is a problem: how can you handle objects which are so thin that they cannot be seen at all with a normal optical microscope?

Tiny robots get a grip on nanotubes

Europe | Posted on August 17th, 2009"The handling and characterisation of these objects has become more and more important in materials science and nanotechnology," says Volkmar Eichhorn of the University of Oldenburg and its associated institute, OFFIS. "They have a huge application potential in various products."

One solution, developed by the EU-funded NanoHand project, is to use mobile microrobots equipped with delicate handling tools. NanoHand builds on the work of ROBOSEM, an earlier EU project that developed the basic technologies that are now being put into effect.

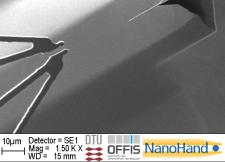

The robots, about two centimetres in size, work inside a scanning electron microscope where their activities can be followed by an observer. "The whole set-up is integrated into the vacuum chamber of the microscope," Eichhorn explains. "There is a glass plate where these mobile microrobots can walk around."

Microgrippers

Each robot has a ‘microgripper' that can make precise and delicate movements. It works on an electrothermal principle to open and close the jaws, much like a pair of tweezers.

The jaws open to about 2 micrometres and can pick up objects less than 100 nanometres in size. "[It is] really able to grip micro or even nano objects," Eichhorn says. "We have handled objects down to tens of nanometres."

At that scale, the intermolecular forces between objects are stronger than gravity. Once a nanotube has been picked up it will stick to the jaws of the gripper and cannot easily be dropped into position. The team have had to develop novel ‘pick-and-place' techniques to get around this problem.

One approach is to glue the tube in its final position using electron beam-induced deposition. Another is to use geometrical principles to ensure that the intermolecular forces pulling the tube towards its intended location are greater than those holding it in the jaws of the gripper.

"Worldwide, we are the first project that has really realised the automated microgripper-based pick-and-place experiments," Eichhorn notes. "The new thing is the high accuracy and the small scale of the objects - in the range of tens or hundreds of nanometres - and the excellent control and software architecture being built around this whole set-up facilitating a high degree of automation."

Better microscope

An early success of the project was to improve the performance of an atomic force microscope, a workhorse of nanotechnology.

The microscope ‘feels' a surface by dragging a fine probe over it. Individual atoms can be sensed and a picture built up. But conventional probes have a pyramid-shaped tip which cannot follow the hills and valleys of deeply corrugated surfaces. The NanoHand team used their microrobots to automatically pick up a carbon nanotube and attach it to the tip, so greatly improving the probe's ability to sense deep valleys.

This achievement was made with the ‘NanoLab' demonstrator, designed for use in experimental laboratory situations.

In parallel, the industrial partners have developed a more robust ‘NanoFab' demonstrator, better suited to the needs of industry. They are exploring how the technology could be used for rapid prototyping of new designs for microchips. One idea is to use carbon nanotubes as ‘interconnects', the fine wires that make the electrical connections to a chip. Because of their high electrical conductivity, carbon nanotubes dissipate less heat than copper and allow circuits to be packed more densely.

This application is of particular interest to STMicroelectronics, one of the project partners and a heavyweight maker of microchips. "They would like to have a nanorobotic system where they can do fast and rapid characterisation of these devices," says Eichhorn. "Up to now, it was a manual, teleoperated characterisation which was very time consuming."

Early exploitation

Many other industrial applications are possible, including novel devices that could not be constructed any other way. Applications in composite materials, displays and new kinds of transistors are all being talked about.

Other groups are working on methods of handling nanotubes, especially in the USA, Japan and China, but the NanoHand system of microrobots and microgrippers is proving effective and reliable. "It's very promising for nanotechnology applications," says Eichhorn.

From the start, the project has been run with commercialisation in mind and the first product is already on the market. Two of the industrial partners, Tescan and Klocke Nanotechnik, are collaborating to sell a scanning electron microscope equipped with a nanopositioning system based on NanoHand technology.

The Technical University of Denmark (DTU Nanotech) intends to set up a spin-off to market the microgrippers and the Ecoles Polytechniques Fédérale de Lausanne (EPFL) is seeking to further develop the microrobots to the point where they can be commercialised.

NanoHand received funding from the ICT strand of the EU's Sixth Framework Programme for research.

####

For more information, please click here

Copyright © ITC Results

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Videos/Movies

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

New X-ray imaging technique to study the transient phases of quantum materials December 29th, 2022

![]() Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

Solvent study solves solar cell durability puzzle: Rice-led project could make perovskite cells ready for prime time September 23rd, 2022

![]() Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Scientists prepare for the world’s smallest race: Nanocar Race II March 18th, 2022

Molecular Nanotechnology

![]() Quantum pumping in molecular junctions August 16th, 2024

Quantum pumping in molecular junctions August 16th, 2024

![]() Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Tools

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

Japan launches fully domestically produced quantum computer: Expo visitors to experience quantum computing firsthand August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||