Nanotubes & Buckyballs

Click here to see 1.35 MB full resolution animation.

Courtesy and © Erik Victor

|

Rocky Rawstern

Editor NanoNews-Now

|

Nanotubes

This article is not meant as a technical paper, but rather an overview of nanotubes and buckyballs, and their applications (current and future). For a technical point of view, see the Useful Links section.

In this section of our report, I will concentrate on nanotubes, as they seem to have the greatest number of (and most near-term potential for) mundane possibilities. I say "seem to have" because science has the amazing ability to surprise us - yanking us right out of our comfort zones - so we may find that next week or next year buckyballs leap-frog nanotubes as the "material of choice" for one near-term application or another, and create a whole new industry, or several.

Nanotubes and buckyballs are siblings within the "fullerene" family. Collectively, "carbonaceous materials" such as nanotubes and buckyballs are, like diamond and graphite, members of the same family. Nanotubes are also referred to as "buckytubes" owing to their close relationship to buckyballs.

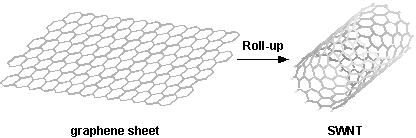

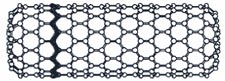

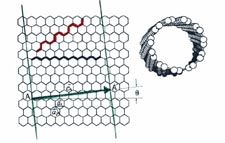

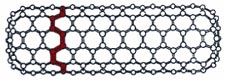

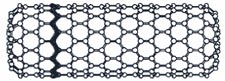

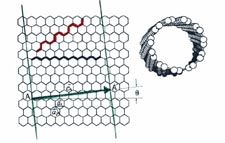

A nanotube can be thought of as a hexagonal network of carbon atoms that has been rolled into a cylinder, although no "rolling" is used in their manufacture. Closed nanotubes are "capped" with half of a fullerene molecule at each end.

Nanotubes are small, in some cases less than a nanometer - one billionth of a meter - in diameter. Single-nanotubes have been produced in lengths in the mm range, and "spun" fibers more than 100 meters have been created at the University of Cambridge, in a process similar to spinning wool (but not out of continuos single-nanotubes, thereby reducing their mechanical and electrical properties).

In describing nanotubes, CMP-Cientifica offers this: "Strictly speaking, any tube with nanoscale dimensions, but generally used to refer to carbon nanotubes (CNT's), which are sheets of graphite rolled up to make a tube. A commonly mentioned non-carbon variety is made of boron nitride, another is silicon. These noncarbon nanotubes are most often referred to as nanowires. The dimensions are variable and you can also get nanotubes within nanotubes, leading to a distinction between multi-walled (MWNT) and single-walled nanotubes (SWNT). Apart from remarkable tensile strength, nanotubes exhibit varying electrical properties (depending on the way the graphite structure spirals around the tube, and other factors, such as doping), and can be superconducting, insulating, semiconducting or conducting (metallic)." MWNT's can be thought of as Russian Nesting dolls (matrioshka) - they fit one inside the other, multi-layered.

While other researchers may have created or visualized nanotubes earlier, it was in 1991 that NEC scientist Sumio Iijima used high-resolution transmission electron microscopy to investigate the materials deposited on an arc-evaporation cathode he was using for the synthesis of fullerenes. What he found were multi-walled CNTs rather than single-walled. He is most often given credit for "discovering" them, even though they are a regular by-product of several ordinary processes, such as candles burning, and what we have labeled as "soot." At bit more on their history can be found here, and their basic structure is described here and here

In general, SWNT's are relatively difficult to produce, and seem to have the greater number of possibilities, while MWNT's are easier to produce, but due to their complexity, are so far more difficult to understand and use. SWNT's can be either conducting (with a current carrying capability more than 100 times that of copper) or semiconducting, which makes them candidates for many electrical applications.

According to researchers at Rice "There are 56 varieties, each of which have subtle differences in diameter or physical structure. These physical differences lead to marked differences in electrical, optical and chemical properties. For example, about one-third are metals, and the rest are semi-conductors."

Some of the many types of nanotube include:

Non-carbon nanotubes are usually called nanowires.

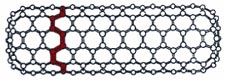

Wikipedia describes the reasons that NT properties can vary: Additionally, there are a large variety of forms of each of these, identified by a two-digit sequence. The first digit indicates how many carbon atoms around the tube is. The second digit determines the offset of where the nanotubes wrap around. If the second digit is a zero, the nanotubes are called "zigzag." If both digits are the same, the nanotubes are called "armchair." Otherwise, they are called "chiral."

"Armchair" nanotube

|

"Zigzag" nanotube

|

"Chiral" nanotube

|

How are they created?

Three common methods are succinctly described by Michaël Daenen et al. (*) in their Wondrous World of Carbon Nanotubes website:

- Arc Discharge: Connect two graphite rods to a power supply, place them a few millimetres apart, and throw the switch. At 100 amps, carbon vaporises and forms a hot plasma.

- Chemical Vapour Deposition: Place substrate in oven, heat to 600 degrees C, and slowly add a carbon-bearing gas such as methane. As gas decomposes it frees up carbon atoms, which recombine in the form of NT's.

- Laser Ablation (vaporization) [AKA: Pulsed Laser Vaporization]: Blast graphite with intense laser pulses; use the laser pulses rather than electricity to generate carbon gas from which the NTs form.

(*) R. de Fouw, B. Hamers, P.G.A. Janssen, K. Schouteden, M.A.J. Veld

Where are they being used today?

Today, CNT's are being used in batteries (well over 60% of Lithium-ion batteries now contain nanotubes in the graphitic material, according to Dr. David Tomanek), fuel cells, sensors, high-strength composites, electrostatic paint applications, cold cathodes in X-ray devices, and catalysts. According to the NASA Center for Nanotechnology "CNT exhibits extraordinary mechanical properties: the Young's modulus is over 1 Tera Pascal. It is stiff as diamond. The estimated tensile strength is 200 Giga Pascal. These properties are ideal for reinforced composites." In plain-speak, CNT's appear to be the strongest material discovered to-date, exhibiting strength 100 times that of steel, at 1/6th the weight.

Some of the many potential uses for nanotubes:

- energy-storing electronic textiles

- artificial muscles

- catalyst supports

- nearly impenetrable bullet-proof vests and body armor

- hydrogen, ammonia, humidity, and pollution sensors

- DNA biosensors, immunosensors, and health monitoring sensors

- biological sensors, for applications such as:

monitoring hydrogen levels in premature babies

quality control in food production plants

pollution monitoring in truck and auto engines

- biomedical sensors (small enough to pass through cells, and not trigger immune response)

- biological and chemical warfare agent sensors

- semiconductor devices

- field-effect transistors (FET)

- field emission displays (FED) for large-area TV's

- advanced generation high resolution flat panel displays

- light emission devices

- silicon etching

- molecular electronics

- heat-conducting applications

- supercapacitors

- advanced reinforced composites

- conductive adhesives, coatings, caulks, paints, and sealants

- fuel cells

- nanofiltration

- reverse osmosis

- nanofluidic devices (such as lab-on-a-chip)

- advanced atomic force microscopes

- nano-motors and mechanisms

- nanoscale tools, such as tweezers

- sports equipment (tennis racquets, yacht masts, fishing rods, etc.)

- earthquake-resistant buildings or towers

- frictionless, low-wear bearings and other nanoscale components

- solid lubricant or as additives

Many of the sensors mentioned above are currently being studied and are expected to be produced in 2004 - 2005 by Applied Nanotech of Austin, Texas.

What's keeping us from using them in other applications?

Since nanotubes tend to stick together or "clump," one of the remaining difficulties to realizing the full potential of SWNT's remains sorting the metallic from the semiconducting nanotubes. Rice News reported that researchers at Rice and the University of Illinois at Urbana-Champaign are the first to chemically select and separate carbon nanotubes based on their electronic structure. "Other than low-cost mass production, thereís no bigger hurdle to overcome in carbon nanotechnology than finding a reliable, affordable means of sorting single-walled carbon nanotubes," said Richard Smalley, University Professor and director of Riceís Carbon Nanotechnology Laboratory. "If we can develop new technology based on electronic sorting and reliably separate metallic nanotubes from semi-metallic and semi-conducting varieties, weíll have a terrific tool for nanoscience."

And as repored at NanotechWeb "two researchers - Ralph Krupke and Frank Hennrich at the FZK research centre in Karlsruhe and colleagues at Karlsruhe University - have developed a technique based on electrophoresis that can extract the metallic nanotubes from such a mixture. The ability to separate nanotubes like this will be essential if devices made from nanotubes are to become a reality. The researchers say that their technique, which can remove metallic nanotubes with about 80% purity, and only works for small volumes." Further, as NanoToday reported in December 2003, several years ago Michael Strano (professor of chemical and biomolecular engineering at Illinois) "developed a technique for breaking up bundles of nanotubes and dispersing them in water laced with a surfactant. Now Strano, together with Monica Usrey and Paul Barone, have teamed up with (James) Tour and Christopher Dyke to apply the same reaction chemistry to the surfaces of nanotubes in order to select metallic tubes over semiconductors."

In the past, another key obstacle to commercialization was scalability - producing significantly greater quantities at lower per-gram prices. Today, many companies have either "geared-up" or are doing so. Companies such as CNRI, Hyperion Catalysis International, Nanocyl, NanoLedge, Nanostructured & Amorphous Materials, and Rosseter Holdings Limited are producing hundreds to thousands of grams per day, many with the expectation of ramping up production significantly when customer demand increases.

Reporting for the Houston Chronicle, Eric Berger wrote (in March of 2004): "When Carbon Nanotechnologies Inc. built its first pilot plant three years ago, it could make 1 pound of nanotubes a year. Six pilot plants later, the company is in final testing of a unit capable of making 20 pounds a day. Routine operation is expected within weeks. Later this year, the company plans to complete a unit capable of continuous operation, making 100 pounds a day. And if all goes well, a full-scale plant, likely to be built in the Ship Channel area, could begin manufacturing 1,000 or even 10,000 pounds a day in late 2005."

How much is being produced?

I recently spoke with Founder and Former Vice President of SouthWest NanoTechnologies, Mike Moradi about world-wide NT production capacity. He estimates that "roughly 15-20 Lbs/day (are produced), which includes low-quality material. High-end purified SWNT capacity is much lower, at perhaps 2-4 Lbs/day. This capacity will increase rapidly, as we're seeing the first real applications start to scale-up." And in an email conversation with Dr. C. Rom·n Vas, Managing Director and Senior Scientific Consultant at Cient"fica, she kindly pointed me to their March 2004 Nanotubes Report (© Cient"fica 2004), within which they "identified and directly contacted all 44 suppliers world-wide," yielding the following estimates:

- Current estimated global production of carbon nanofibers is more than 40 tons a year, and is expected to reach more than 58 tons by 2006.

- Total global production capacity of multi-walled nanotubes is higher than 99 tons a year and expected to increase to at least 268 tons annually by 2007.

- Current global production capacity of single walled nanotubes can be estimated to be at least 9000 kg/year. The production is expected to increase up to more than 27 tons by 2005 and to reach 100 tons by 2008.

"Taken altogether, the possible impact of carbon nanotubes on the world is immense, with market sizes for new products based on them running into the hundreds of billions if they fulfill all their potential. A lot of this could be seen within 5 years, with more following within a decade."

In a recent article for the Baltimore Sun, Frank D. Roylance interviewed several leading CNT producers, including Ray McLaughlin, executive vice president of Carbon Nanotechnologies Inc. "Carbon Nanotechologies is probably the world's leading producer of carbon nanotubes. But the company's current capacity (1) is 20 pounds a day, all for customers' research and development needs.

'We expect to have 100 pounds per day capacity available by midyear,' McLaughlin said. 'Then we expect to be able to ramp up to fit whatever the demand schedule dictates. And we're expecting sometime in 2005 or 2006 that could be 1,000 to 5,000 pounds a day.' "

(1) Capacity, vs. actual production quotas.

How much do they cost?

NT's are sold in bulk (mixed) form for as little as $3 - $7 per gram, and in "functionalized" forms for as much as $900 per gram. See our ongoing Survey for details. Of course supply (production capability) and demand will undoubtedly drive down the price, at which time they will become cheap enough for many more additional applications.

|

Since the discovery of carbon nanotubes in 1991, scientists have been searching for other types of one-dimensional nanomaterials. In 2001, a breakthough was made at Georgia Tech by Prof. Z.L. Wang's group for reporting the nanobelt structure (Z.W. Pan, Z.R. Dai and Z.L. Wang, Science, 209 (2001) 1947). This paper was the first paper that reports another family of structurally controlled nanomaterials. In this paper, ultra-long belt-like, quasi-one-dimensional nanostructures (so called nanobelts or nanoribbons) have been successfully synthesized for semiconducting oxides of zinc, tin, indium, cadmium and gallium, by simply evaporating the desired commercial metal oxide powders at high temperatures. The as-synthesized oxide nanobelts are pure, structurally uniform, single crystalline and most of them free from dislocations; they have a rectangular-like cross-section with typical widths of 30 - 300 nm, width-to-thickness ratios of 5 - 10 and lengths of up to a few millimeters. The belt-like morphology appears to be a unique and common structural characteristic for the family of semiconducting oxides with cations of different valence states and materials of distinct crystallographic structures. This was a breakthrough in nanomaterials synthesis by achieving structural control. The paper was the second most cited paper in chemistry from 2001-2003.

Z.L. Wang, Zhengwei Pan and Zurong Dai "Semiconducting Oxide Nanostructures", US Patent No. 6,586,095

Zhong Wang, Ph.D.

Professor and Director, Center for Nanoscience and Nanotechnology

Director of Electron Microscopy Center

From our NanoTech-Transfer patent report. Click here to learn more.

|

Other Possibilities - From The Inconceivably Small To The Unimaginably Large

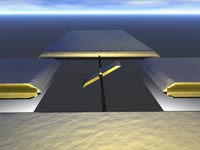

A news release we posted in July of 2003, and titled Using nanotubes and etched silicon, UC Berkeley physicists build world's smallest motor reports on the creation of the world's first nano-scale motor - an actual purpose-built mechanism, nearly at the size that Mother Nature Herself does.

"Only 15 years after University of California, Berkeley, engineers built the first micro-scale motor, a UC Berkeley physicist has created the first nano-scale motor - a gold rotor on a nanotube shaft that could ride on the back of a virus. 'It's the smallest synthetic motor that's ever been made,' said Alex Zettl, professor of physics at UC Berkeley and faculty scientist at Lawrence Berkeley National Laboratory. 'Nature is still a little bit ahead of us - there are biological motors that are equal or slightly smaller in size - but we are catching up.'

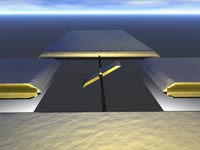

A series of scanning electron microscope pictures of the spinning rotor of a nanomotor fabricated in the lab of UC Berkeley physicist Alex Zettl. The entire electric motor is about 500 nanometers across, 300 times smaller than the diameter of a human hair. (Courtesy of and © Copyright: Zettl lab. All rights reserved.)

|

Click for larger version

Depiction of the nanomotor built by the Zettl research group at UC Berkeley and Lawrence Berkeley National Laboratory. The gold rotor turns on a carbon nanotube shaft, powered by two charged stators patterned on a silicon surface. (Click to enlarge.

Courtesy of and © Copyright: Zettl lab. All rights reserved.)

See also the Video located here, and labeled "World's smallest motor (Quicktime)"

|

The electrostatic motors represent a milestone in nanotechnology, and prove that nanotubes and other nanostructures several hundred times smaller than the diameter of a human hair can be manipulated and assembled into true devices.

Zettl and other scientists had previously made transistors from nanotubes, but this device is different, he said.

'It's the first device where you can put external wires on it and have something rotating, something you can control,' he said. 'We are pushing a lot of different technologies to the edge.'

Such motors could have numerous uses, Zettl said. Because the rotor can be positioned at any angle, the motor could be used in optical circuits to redirect light, a process called optical switching. The rotor could be rapidly flipped back and forth to create a microwave oscillator, or the spinning rotor could be used to mix liquids in microfluidic devices.

The motor is about 500 nanometers across, 300 times smaller than the diameter of a human hair. While the part that rotates, the rotor, is between 100 and 300 nanometers long, the carbon nanotube shaft to which it is attached is only a few atoms across, perhaps 5-10 nanometers thick.

The motor's shaft is a multiwalled nanotube, that is, it consists of nested nanotubes much like the layers of a leek. Annealed both to the rotor and fixed anchors, the rigid nanotube allows the rotor to move only about 20 degrees. However, the team was able to break the outer wall of the nested nanotubes to allow the outer tube and attached rotor to freely spin around the inner tubes as a nearly frictionless bearing."

In closing, Zettle states "People will build on this."

The Space Elevator

(Make sure to read the October 2004 Report, when we cover the Space Elevator in depth)

One of the central components of a successful space elevator is a super light-weight, super strong material (think nanotube cable), that can be spun out to phenomenal lengths (to geostationary Earth orbit, at around 36,000 kilometers). The cable would be attached to a ground platform, at the Equator. The end in space would be attached to a counterbalance mass, possibly a captured asteroid. Electromagnetic propulsion is a candidate for launch and delivery; having already been jump-started by current high-speed railway efforts.

In an article titled Audacious & Outrageous: Space Elevators by science writer Steve Price, we learn about the Space Elevator. "Yes, ladies and gentlemen, welcome aboard NASA's Millennium-Two Space Elevator. Your first stop will be the Lunar-level platform before we continue on to the New Frontier Space Colony development. The entire ride will take about 5 hours, so sit back and enjoy the trip. As we rise, be sure to watch outside the window as the curvature of the Earth becomes visible and the sky changes from deep blue to black, truly one of the most breathtaking views you will ever see!"

Explained in simple terms by Price "A space elevator is essentially a long cable extending from our planet's surface into space with its center of mass at geostationary Earth orbit (GEO), 35,786 km in altitude. Electromagnetic vehicles traveling along the cable could serve as a mass transportation system for moving people, payloads, and power between Earth and space."

When built as conceived, the space elevator is predicted to greatly reduce the Earth-to-orbit costs of materials, devices, and people. The cost-per-pound to move into space will drop from a current NASA rate of $10,000-$40,000, to a forecasted rate of less than $100. Figure you and your luggage weight 200 pounds - that's $20,000, a bit less than the reported $20M Dennis Tito paid to become the world's first space tourist. "Additional and larger elevators, built utilizing the first, would allow large-scale manned and commercial activities in space and reduce lift costs even further." says Los Alamos National Laboratory.

When asked to estimate when the space elevator would be built, Arthur C. Clarke replied "Probably about 50 years after everybody quits laughing!" With the rapid increase in our understanding of nanotubes, coupled with our ability to ramp up their production and seperate them, the laughter is dying down.

In closing

It seems likely that once we learn just a bit more about them, we will find that nanotubes are the "plastic" of the 21st Century, enabling whole new industries, and enhancing the quality (and perhaps the quantity) of our lives.

Buckyballs

Interview with Nano-C CEO Gordon Fowler, questions by Rocky Rawstern.

Can you talk about a simple description of buckyballs?

"Buckyballs" are naturally occurring, perfectly symmetrical balls of

60 carbon atoms. A C60 fullerene molecule is actually the shape of a

soccer ball. It also resembles the complex configuration of Buckminster

Fullerís geodesic domes. Given its shape, and given that chemists are known

for the amusing names they give new creations, it is not that surprising

that C60 came to be formally called "buckminsterfullerene," or, as

scientists quickly nicknamed it, "the buckyball."

The molecular group known as fullerenes actually contains other

three-dimensional carbon molecules, including C70, C76, C78, and C84 and C90, which

could prove equally (or even more) interesting chemically than C60. To

date, however, all the major research and development efforts have been

focused on C60. (Editor's note: and the recently discovered C50)

For the chemist or the physicist, it was the unique properties of the

closed cage of the molecule that opened a world of wonder and potential

uses when the buckyball was discovered in 1985 (though it was not available

for study and characterization until 1991). The closed cage configuration

is relatively taut and its natural tendency is to relax, which it can do by

bonding with other atoms. Thus the closed cage of the fullerene provides a

driving force for chemical reactions. This tendency, together with the

particular way fullerenes are bonded, makes it very easy to add a large

variety of chemical groups to fullerene cages. The structure of the cage

and the bonding configuration also give fullerenes a high affinity for

electrons, and, given the high number of bonding sites, make fullerenes

uniquely potent as antioxidants. These properties make them react very

quickly and soak up a lot of radicals. In addition, the closed cage

structure, with a molecular diameter of 0.7 nanometers, even permits other

atoms to be placed inside. It is these properties of the fullereneís closed

cage that have opened a world of rich chemical uses.

The National Science Foundationís comparison of the discovery of fullerenes

with that of benzene is in fact very appropriate. Benzene, which forms a

ring of carbon and hydrogen atoms (C6H6), became the basis for a whole

branch of chemistry known as aromatic chemistry that has had an enormous

impact on modern life. It is estimated, for example, that 90% of all

pharmaceuticals produced today contain benzene rings.

Because of the rich chemistry of this new form of carbon, it is expected

that fullerenes will have an equally profound impact in a wide variety of

applications. The new branch of chemistry based on fullerenes is already

developed to the point where thousands of chemical derivatives have been

made and whole textbooks are devoted to different aspects of the molecule.

One indication of the significance corporate business sees in fullerenes is

in Sony Internationalís annual report for 2003. There Sony announced that

its R&D is moving away from the "twentieth-century era centered on silicon

and to an era centered on carbon." It considers "fullerenes and various

organic materials" as the symbols of this new age.

How are buckyballs produced, and in what quantity (today)?

Throughout the 90s, researchers relied on a simple laboratory

process, the carbon arc method, for producing fullerenes. Nevertheless, the

inefficiencies of the carbon arc method, and the post-processing required to

separate the fullerenes from the soot, made the cost prohibitively high for

commercial applications. The price for producing C60 through the carbon arc

method did decrease through the 90s and leveled out at $25/gram

($25,000/kg) in 2001.

Jack Howard, founder of Nano-C and professor emeritus from MIT, knew

combustion synthesis held the key for creating a low-cost, scalable way to

produce fullerenes. For 12 years in his combustion research group at

MIT, Dr. Howard led research on the production of fullerenes by combustion

synthesis. In 2001, he received the license and all future rights to the

first generation technology and founded Nano-C.

In Japan, Frontier Carbon and joint venture between Mitsubishi Corporation and Mitsubishi Chemical licensed the first generation technology and have created a facility reportedly capable of producing 40 metric tons/year to support the Japanese and Asian markets.

In October 2003, Nano-C announced the second generation of Howard's combustion synthesis process. See: Nano-C delivers efficient, scalable combustion technology for fullerenes production. Nano-C's current process dramatically reduces the production costs of fullerenes, by a factor of 10 or more, down to under $200/kg in some cases.

Nano-C uses its 2nd generation pre-pilot production facility in Westwood to supply US and European requirements.

Please describe some of the current and near-future (within 5 years)

uses of buckyballs.

Due to high initial production costs, only now are applications being

more broadly commercialized for fullerenes. In particular, fullerenes are

being tested and used for production of:

- BioPharmaceuticals, including neuroprotectants (addressing Alzheimerís, Parkinsonís, and Lou Gehrigís diseases, and stroke damage), AIDS protease inhibitors, and atherosclerosis medications;

- Personal care products, including cosmetics, anti-aging creams, anti-wrinkle creams and after-burn creams;

- Conducting polymers and polymer electronics, including photo detectors, solar cells, EMI shielding and transistors;

- Specialty polymers, including membranes for hydrogen micro fuel cells, quick-set resins for fiber optic cable, polyimides for electronic packaging, low friction ultra high molecular weight polyethylene; and anticorrosion coatings;

- Commodity polymers or Fluoropolymers (Teflon-like polymers);

- Diamond-like carbon coatings, for hard-disk drives; and

- Materials/Electronics, for capacitor electrodes.

Please talk about some of the factors limiting their use.

The biggest limitation has been cost. With that issue out of the way, we anticipate increasing the number of products that have already been designed, and will begin to move to market.

Are existing production methods scalable, or will new techniques need to

be developed to meet industry demands in the future?

Nano-C's current process dramatically reduces the production costs of fullerenes - by a factor of 10 or more - down to under $200/kg in some cases, making it the most scalable process available today, and capable of supporting industrial production levels.

How does academia play a role in understanding the science underlying

buckyballs?

While much research has been done, there is still a need to for continuing research on applications.

Please speculate about how buckyballs might be used in 5 to 10 years.

In the 5 to 10 year time frame we anticipate wide use of fullerenes in a number of markets. We occasionally need to remind ourselves that fullerenes are really a high performance molecule of carbon and they will likely be used in areas that other forms of carbon might be used today. In particular we think there will be widespread use in pharmaceuticals in that timeframe as fullerenes' unique properties and ability to act as a scaffold for other molecules will lead to new drugs and therapies.

|

Gordon Fowler has a long track record of commercializing new technologies, serving in a number of organizations as president with responsibilities for P&L, strategic vision, and the orderly implementation of new technologies to facilitate growth. He brings to Nano-C a strong background in manufacturing, plant management, and operations as well as significant international experience and a working knowledge of the investment community. Prior to joining Nano-C, Fowler had a consulting practice specializing in business transformation with particular emphasis on leveraging technology to improve performance.

Nano-C is a world leader in fullerene production technology. They have successfully developed a proprietary combustion synthesis process based on technology invented by Jack Howard, Professor Emeritus at MIT.

Nano-C holds numerous patents for the combustion synthesis method of fullerene production and has executed licensing agreements with organizations that are currently commercializing fullerenes in Asia.

To find out more about the history of fullerenes and Nano-C's combustion synthesis technology click here.

|

Return to Top

SURVEY 1

By Rocky Rawstern

In this survey, I spoke with individuals who are doing leading edge research into nanotubes and buckyballs, and asked them to respond to the following questions:

1. Considering their potential to reduce weight and/or increase the strength of materials, under what conditions are we likely to start seeing widespread use of nanotubes (in industries such as automobile, airplane, and space vehicle manufacturing, and others where weight and strength are paramount)?

2. Under what conditions are we likely to see their use in the health/medical and electronics industries?

3. Given the recent buckyball/fish and nanotube/rat studies (1), what other precautions (if any) should be implemented in labs and production facilities, and what (if anything) should the public be worried about regarding nanoparticles?

4. In your opinion, regarding nanotubes and buckyballs, what are the:

- Most significant discoveries or developments in the past year.

- Most promising (or likely) applications in next five to ten years.

(1) Buckyball Brouhaha and As Uses Grow, Tiny Materials' Safety Is Hard to Pin Down

Responding were:

Dr. David Tomanek

Dr. Thomas J. Webster

Dr. Zvi Yaniv

Dr. Jonathan N. Coleman

Dr. David Tomanek, Professor of Physics, Michigan State University (home page), Chairman Rosseter Holdings Ltd.

Considering their potential to reduce weight and/or increase the strength of materials, under what conditions are we likely to start seeing widespread use of nanotubes (in industries such as automobile, airplane, and space vehicle manufacturing, and others where weight and strength are paramount)?

We expect a wider use of specialized nanotube-based composite materials. Rosseter, in collaboration with a European team, has observed significantly enhanced electrical conductivity and material strength of plastics upon addition of nanotubes. The optical properties at low loading levels are barely changed. Rosseter material (nanostructured carbon/nanotubes) now appears best due to good performance/price ratio.

Under what conditions are we likely to see their use in the health/medical and electronics industries?

Nanotubes are currently used in Li-ion batteries * (well over 60% world-wide now contain nanotubes in the graphitic material). Lead-acid batteries will come next -- with a doubled lifetime. * They are there on purpose, at extra cost, to enhance performance.

Given the recent buckyball/fish and nanotube/rat studies, what other precautions (if any) should be implemented in labs and production facilities, and what (if anything) should the public be worried about regarding nanoparticles?

The medical studies performed so far are pretty superficial and inconclusive; one study contradicts the other significantly (difference being between "lethal" and "no effect"). It is important to point out that nanostructures must be investigated differently from common chemicals or other microstructures (asbestos) in terms of toxicology. Everything depends drastically on the chemical functionalization of the nanostructures. Independent of sugar coating, cyanide is cyanide is bad. A surfactant covered nanotube/buckyball behaves very differently from an acid-treated nanotube.

Dr. Tomenek went on to suggest attending NT'04: International Conference on the Science and Application of Nanotubes, the premiere nanotube conference, as a way to learn more. If you have any interest in nanotubes, this is the one event not to be missed (July 19-24, 2004, San Luis Potos", MÈxico).

Dr. Thomas J. Webster, Assistant Professor of Biomedical Engineering, Assistant Professor of Materials Engineering, Purdue University

Considering their potential to reduce weight and/or increase the strength of materials, under what conditions are we likely to start seeing widespread use of nanotubes (in industries such as automobile, airplane, and space vehicle manufacturing, and others where weight and strength are paramount)?

I come from the biomaterials avenue where strength is also quite important. Particularly for weight bearing implants (like the hip, knee, or ankle) maintaining strength over time is critical so that the patient can lead a normal active lifestyle. So we are investigating not only the weight bearing potential, but also the ability for these materials to grow new bone. For orthopedic implants, new bone growth is also important to anchor the implant. We see tremendous opportunity for carbon nanotubes/nanofibers as orthopedic implants since they increase bone formation when compared to traditional materials ñ like titanium. In fact the smaller we make them, the more new bone growth we get.

Under what conditions are we likely to see their use in the health/medical and electronics industries?

See above, but to add I think in neural implant applications as well. Since carbon nanotubes have unique conductivity properties, we have also been looking at neural cell interaction on carbon nanotubes and see (similar to above) better neural cell responses on smaller carbon nanotubes. This means such materials could be used as electrodes in helping to rehabilitate damaged nerve tissue. We have also seen decreased scar tissue formation around carbon nanotubes. Scar tissue formation around silicon is a main problem for the use of the materials as electrodes as it decreases conductivity.

Given the recent buckyball/fish and nanotube/rat studies, what other precautions (if any) should be implemented in labs and production facilities, and what (if anything) should the public be worried about regarding nanoparticles?

Such studies need to be looked at very carefully and verified in other independent labs. In my opinion, we need many more studies like that which can signify whether these materials should be implanted or not. In our lab, we have seen significant agglomeration of nanoparticles when exposed to proteins in the body. In fact, such nanoparticles agglomerate into micron particles ñ similar to what is implanted today. If these result end up signifying that nanophase materials in general should not be implanted or used, we need to look at ways in which to create nanostructured roughness without the use of these particles (like chemical etching techniques or e-beam lithography). This is because in my lab (and others) increased bone, vascular, bladder, cartilage, and responses from nerve cells have been observed on nanostructured compared to conventional surfaces (regardless of how they are created).

In your opinion, regarding nanotubes and buckyballs, what are the:

- Most significant discoveries or developments in the past year.

For tissue engineering, I believe one of the more significant findings was to create a porous scaffold of carbon nanotubes as demonstrated by Prof. Ajayan at RPI. Other than that, the evidence that bone (and other tissue) regeneration is enhanced on carbon nanotubes.

- Most promising (or likely) applications in next five to ten years.

In my biased opinion, most promising is as a component or coating in orthopedic implants- again a lot more work is needed especially in animal studies for this context.

Dr. Zvi Yaniv, President, Director, and CEO Applied Nanotech, Editor NanoExpress.

Considering their potential to reduce weight and/or increase the strength of materials, under what conditions are we likely to start seeing widespread use of nanotubes (in industries such as automobile, airplane, and space vehicle manufacturing, and others where weight and strength are paramount)?

I agree with you that CNTs in particular can be applied to reduce weight and increase strength. One need to be very careful, however, to take into account two important points:

- Only single wall carbon nanotubes have these excellent properties of strength. These properties are anisotropic and as a result alignment will be needed.

- Single wall carbon nanotubes like to stick together. When they do so they loose their specific properties compared with when they are isolated. It would be very important to obtain high quality dispersion of single wall carbon nanotubes compatible with the applications of interest.

Under what conditions are we likely to see their use in the health/medical and electronics industries?

Another point I would like to make is that again, the single wall nanotubes have semiconductor properties and techniques must be developed in order to select specific single wall nanotubes with specific chiralities and locate them in mass production with nanometric accuracy. It is my opinion that these techniques will come from the convergence of nano and biotechnologies. With respect to medical applications the only early application I can see is to use CNTs in conjunction with different enzymes and antibodies for sensing.

Given the recent buckyball/fish and nanotube/rat studies, what other precautions (if any) should be implemented in labs and production facilities, and what (if anything) should the public be worried about regarding nanoparticles?

With respect to precautions, look, we did not invent nanoparticles, they always existed. We live with them, we breath them for as long as humanity exists. But, one must take all the precautions. So I strongly recommend that when people play with nanoparticles than can "fly", normal precautions of control breathing and control exhaust must be taken.

With respect to production facilities, once the carbon nanotubes are in an ink, a polymer or in other solid composite I do not see serious problems.

In your opinion, regarding nanotubes and buckyballs, what are the:

- Most significant discoveries or developments in the past year.

The most significant discovery in the last year I could say is the demonstration that our company ANI made at IDW in Japan showing tremendous progress in making large area CNT TVs using only printing techniques and showing good gray scale capability in the picture. Other interesting use of CNTs I would like to mention is what Hitachi showed a portable computer using methanol fuel cells whereby the support for the catalyst were carbon nanotubes.

- Most promising (or likely) applications in next five to ten years.

The most important applications of carbon nanotubes in the next five years in order of my choice of importance and market magnitude are:

- large area CNT TVs

- nanobiosensors

- catalysts for methanol fuel cells

- catalysts for NOx reduction

Dr. Jonathan N. Coleman, Materials Ireland Polymer Research Centre, Department of Physics, Trinity College Dublin. Home page.

Considering their potential to reduce weight and/or increase the strength of materials, under what conditions are we likely to start seeing widespread use of nanotubes (in industries such as automobile, airplane, and space vehicle manufacturing, and others where weight and strength are paramount)?

Firstly let me say that of all the potential applications of carbon nanotubes, I think that the most viable in the short term are those involving nanotubes as functional agents in polymer or epoxy based composites. This is because the initial studies involving composites are already reaching completion. The two most promising areas are electrical conductivity enhancement and mechanical reinforcement. It is now routine to produce polymer-nanotube composites with conductivities high enough for anti-static or EMI shielding applications. In fact such composites are already in use in the automobile industry.

However I would see mechanical reinforcement as the best candidate for viable applications. At this stage all the pieces of the mechanical puzzle have been put together. For a long time much of the work on reinforcement was a bit piecemeal with researchers demonstrating reinforcement in various unrelated systems. Recently however a number of papers have come out, outlining big advances. Probably the most important was the Nature paper by Dalton et al (1). This work showed for the first time that polymer-nanotube fibres with useful properties could be produced in large quantities, in an industry friendly manner. These fibres had reasonably high modulus, the strength of steel and toughness far exceeding any known material. However the real advance is that the process used was designed to be scaled up using techniques already used in industry.

In addition a paper was recently published demonstrating that low diameter multiwalled nanotubes are the most promising for mechanical applications (2). This work is important as it shows that you don't need expensive SWNT but can get very good results using cheap catalytic multiwalled NT.

Finally a third paper (by the correspondant) will be published in Advanced Functional Materials in a month or so, outlining the reinforcement mechanism for bulk plastic reinforcement (3). This work is important as it demonstrates that by using functionalisation, in principal any polymer can be reinforced using nanotubes. This is what industry wants and now we are finally able to deliver.

However, two problems remain. The first is relatively minor. Much of the work on bulk reinforcement has been carried out on solution processed materials. These results need to be repeated using the type of thermal processing favoured by industry. This work is underway in a number of groups. However it needs to be carried out for functionalised nanotubes to show that thermal processing does not remove the functionalities.

The second problem is a bit more serious. The fibres produced in the Dalton et al paper are estimated to cost ~3 cent per meter. This is mostly due to the high cost of the nanotubes themselves and is far to high for all but the most specialist applications. This is the crux of the matter. We can now readily make nanotube based composite fibres of reasonable modulus and high strength and toughness. We can now routinely make bulk composite plastics with moduli, strength and toughness that are increased by typically a factor of 4-5. In both cases the density is approximately 1.3 g/cm3 or about 6 times lower than steel. However until pure nanotubes can be made in quantities of at least tonnes per day at a (very) low price these very useful materials will not be viable for any large scale commercial application.

Bottom line: The applications are there, its now up to the producers to get the price down.

(1) Alan B. Dalton, Steve Collins, Edgar Munoz, Joselito M. Razal, Von Howard Ebron, John P. Ferraris, Jonathan N. Coleman, Bog G. Kim, and Ray H. Baughman, "Super Tough Carbon Nanotube Composite Fibers for Electronic Textiles", Nature, 423 (2003) 703.

(2) M. Cadek, J. N. Coleman, K. P. Ryan, V. Nicolosi, G. Bister, A. Fonseca, J. B. Nagy, K. Szostak, F. BÈguin, W. J. Blau, "Reinforcement of polymers with carbon nanotubes: the role of nanotube surface area" Nano Letters, 2004, 4, 353.

(3) High performance nanotube reinforced plastics: Understanding the mechanism of strength increase, Jonathan N Colemana,*,Ü

, Martin Cadeka,Ü, Rowan Blakeb, Valeria Nicolosia, Kevin P Ryana, Colin Beltona, Antonio Fonsecac, Janos B Nagyc, Yurii K Gun'ko b, Werner J Blaua, Accepted in AFM Feb 2004.

Under what conditions are we likely to see their use in the health/medical and electronics industries?

This is a tougher one altogether. However my feeling is that the situation is somewhat the opposite for these industries compared to the example above. In these cases, cost and bulk production are not an issue as by definition, active devices incorporating nanotubes will be very small. This means that large quantities of NT will not be required. However, in my view the applications are not here at the present. Yes we can make transistors, inverters and sensors etc out of nanotubes. However, to really make an impact in the medical or electronics industry, large-scale integration will be necessary. By this I mean a very large number of individual nanotube based units will have to work together such as a large number of transistors on a chip. While demonstrating the potential of the individual units is a very good first step, I feel that the integration and interconnection of large numbers of units will be much, much harder. This will be the bottleneck and I really don't see Nts making a big impact in the electronics industry for a long time. Certainly not in the short term (or even maybe not in the medium term). The other thing, of course, is that companies like INTEL have been thinking about the breakdown of Moores law for some time. They have a whole host of development plans to buy more time using lithography/silicon technology. I don't think that they will actually need nanotechnology for a long time, certainly longer than most academics think.

Given the recent buckyball/fish and nanotube/rat studies, what other precautions (if any) should be implemented in labs and production facilities, and what (if anything) should the public be worried about regarding nanoparticles?

I think we all know that nanotubes are potentially dangerous in analogy to asbestos. As such we need to take all the standard precautions associated with the handling of such materials. However I think this goes without saying in all modern labs. I am a bit more concerned about the public's potential reaction to nanotechnology in general. Public perception is based on the availability of information. If all the public hears are television programs about "gray goo" that will destroy all life on earth, we will have a problem. The last thing we need is nanotechnology becoming the next issue for protest in the mold of GM crops. This issue will not go away and must be tackled. This will involve research scientists working to educate the public on the facts, both positive and negative, surrounding nanotechnology. I'm not saying this will be easy, but it must be done.

In your opinion, regarding nanotubes and buckyballs, what are the:

- Most significant discoveries or developments in the past year.

I am definitely biased but I think the paper by Dalton et al in Nature was the biggest break for nanotubes. This showed that the applications are definitely out there. Now we know exactly what we need to do to get there. This affects all nanotube researchers as the nightmare must surely be that if applications don't come soon, the funding will effectively dry up as it did for C60 research. I should point out that this paper was included in the APS list of physics highlights in 2003.

- Most promising (or likely) applications in next five to ten years.

Who knows? Personally I would like to see nanotechnology succeed in a power generation application such as making solar cells efficient enough to be viable. This is an issue that effects us all (global warming etc). However this work is very difficult and carbon nanotubes are probably not suitable.

Personally I believe that there will be many important developments and applications that will trace their inception to the nanotube research over the last 10 years. However I don't think that the breakthroughs will necessarily involve Carbon nanotubes. In think that the new (mostly) inorganic nanotubes (MoSI, TiO2 etc) that are becoming popular will eventually be the materials that allow the breakthrough applications. This is due to their physical monodispersity. That is you can make them all metallic or all semiconducting or whatever with very little variation. This is what is needed. For example if nanostructured materials ever result in commercially viable solar cells, my guess is that they won't be made of carbon.

However it must be said that Carbon nanotubes have played a huge role and will be remembered for it. This is because even if carbon nanotubes never provide a lasting application, they are the materials that showed us the way.

Return to Top

SURVEY 2

By Rocky Rawstern

In this survey, I spoke with companies who are producing nanotubes, and asked them to respond to the following questions:

1. How have manufacturing methods changed in the past year?

2. How has production volume changed in the past year?

3. What is the most significant discovery or development in the last year?

4. What are some of the most promising (or likely) applications in next five years?

5. By the end of 2004, what is your daily output target (by type)?

6. How are you working through the (potential) toxicological and safety issues?

7. When do you expect to achieve production volumes great enough to drive the cost per pound low enough to make CNTs the material of choice in the automotive, airplane and space industries (and other industries where weight and strength are paramount)?

8. Who are your main clients and how are they using your nanotubes?

Responding were:

David L. Carnahan, NanoLab

Mike Moradi, (formerly) SouthWest NanoTechnologies

Julien Roux, NanoLedge

Subiantoro, CNRI

David L. Carnahan, President NanoLab.

How have manufacturing methods changed in the past year?

We can now routinely check our product with high resolution transmission electron microscopy, so we can examine the nanotubes in fine detail. This helped us to improve quality control, and identify process improvements. Automation also helped us drive down the labor cost.

How has production volume changed in the past year?

Both capacity and production volume increased significantly over the past year, as we brought on automated processes.

What is the most significant discovery or development in the last year?

For the company, we expanded our line of nanoparticles and nanowires in 2003, which are now being commercialized.

What are some of the most promising (or likely) applications in next five years?

Composites will become a significant market for nanotubes in five years. Nearer term applications are more niche oriented.

By the end of 2004, what is your daily output target (by type)?

MWNT 200g

DWNT 10g

How are you working through the (potential) toxicological and safety issues?

We routinely collaborate with researchers conducting toxicology studies.

When do you expect to achieve production volumes great enough to drive the cost per pound low enough to make CNTs the material of choice in the automotive, airplane and space industries (and other industries where weight and strength are paramount)?

The key issue is the discovery of how to harness the properties of the nanotubes in bulk composites. To date, few nanotube properties show up in composites, which tells us that there is nearly no interaction between nanotubes and a matrix phase. When we can access their properties, the composite markets will be open. With the synthesis routes used today, it will be difficult to drive the nanotube cost below $100/kg.

Who are your main clients and how are they using your nanotubes?

Universities were the customers for the past 3 years. Now the customers are from large fortune 500 companies and other startups.

Mike Moradi, Founder and Former Vice President,

SouthWest NanoTechnologies, Inc.

How have manufacturing methods changed in the past year?

In the SWNT industry, several groups are moving away from the older methods (laser, arc, & CVD). They are choosing Fluidized Beds and other high throughput methods, in order to scale production with relatively low costs.

How has production volume changed in the past year?

Serious competitors are scaling production by 10 -100x. Others continue to sell laboratory volumes, using installed capacity.

What is the most significant discovery or development in the last year?

High-throughput functionalization & purification methods have moved the industry closer to the market.

What are some of the most promising (or likely) applications in next five years?

Conductive coatings, adhesives, and composites; passive electronic devices, flat panel displays; fuel cell & battery electrodes.

When do you expect to achieve production volumes great enough to drive the cost per pound low enough to make CNTs the material of choice in the automotive, airplane and space industries (and other industries where weight and strength are paramount)?

I foresee these applications opening up in the $100/lb range for SWNT materials. This price point will likely be reached within 4-5 years.

Julien Roux, NanoLedge.

How have manufacturing methods changed in the past year?

Last year, our main goal was to increase the reliability of our arc discharge process and thus to standardize our SWNT products. We achieve that and we can thus guarantee standardize products to our customer not depending on production batch. That was one of the main requirements of our customers.

How has production volume changed in the past year?

We didn't increase the production capacity, we have worked on reliability. Otherwise, our sales have dramatically increased since these improvements: one year ago we didn't sell all our production capacity; this is the case today.

What is the most significant discovery or development in the last year?

For Nanoledge the most significant developments are dispersions of nanotubes in aqueous and organic solvents. Since 10 months, Nanoledge sells nanotubes based dispersions and these products are a success. With these products, we are supplying to our customer-integrated nanotubes that maximize the advantages of nanotubes. These dispersions allow our customers to integrate easily nanotubes in their products.

What are some of the most promising (or likely) applications in next five years?

In the next five years, the most promising applications are based on electrical conductivity (for ESD and EMI shielding), optical absorption and mechanical reinforcement. The most promising products based on nanotubes will be multifunctional using a combination of these properties.

By the end of 2004, what is your daily output target (by type)?

Nanoledge expects higher production quotas.

How are you working through the (potential) toxicological and safety issues?

We are launching national and European initiatives to study the potential toxicological impacts of nanoparticles.

When do you expect to achieve production volumes great enough to drive the cost per pound low enough to make CNTs the material of choice in the automotive, airplane and space industries (and other industries where weight and strength are paramount)?

Nanoledge and other industrial producers plan mass production of nanotubes in 2006. Prices for MWNT will be lower than 100à/kg.

Who are your main clients and how are they using your nanotubes?

Main clients are working on coatings and are mainly using nanotubes for electrical conductivity.

Subiantoro, Application Dev. Dept., CNRI Division, Bussan Nanotech Research Institute, Inc. (formerly Carbon Nanotech Research Institute Inc. (CNRI)).

How have manufacturing methods changed in the past year?

There is no change as we have established our production technologies.

How has production volume changed in the past year?

Nominal capacity is as reported last year, and as market demand is still fluctuating we been adjusting our production volume.

What is the most significant discovery or development in the last year?

Composite material using our MWNT, especially resin base composite applications.

What are some of the most promising (or likely) applications in next five years?

We still see electrically conducting plastics as the most promising application, followed by high strength composite for structural applications.

By the end of 2004, what is your daily output target (by type)?

Market itself is not yet established so it is difficult to predict output. The main point is how to make new applications using MWNT, so we can expect a "stable" demand.

How are you working through the (potential) toxicological and safety issues?

We have been working internally and externally on that issue, and due also to other reasons such as dispersion/application technique etc., we have been adopting policy not to supply product in the powder form.

When do you expect to achieve production volumes great enough to drive the cost per pound low enough to make CNTs the material of choice in the automotive, airplane and space industries (and other industries where weight and strength are paramount)?

It really depends on the development speed in the market/customers. If the market could utilize the MWNT soon, so it may take 2-3 years to expect a great enough demand and it will enable MWNT/CNT producers to expand their production capacity further and then the cost will be going down. However, if it the product development in the market still needs longer time, MWNT price may hard to reduce in the coming 3-5 years.

Who are your main clients and how are they using your nanotubes?

Automotive and electronic/electric industry, using CNT and conductive filler in the plastic composite. Of course structural applications are also one of the industry's interests.

Why and How to Invest in Entrepreneurial Nanotech vs. Corporate Companies By Pearl Chin - Managing General Partner, Seraphima Ventures |

|

|

The industries that nanotechnology will likely have a disruptive effect on in the near term include the following:

(Amounts are Billions of US Dollars)

|

$1,700 |

Healthcare |

|

$600 |

Long Term Care |

|

$550 |

Electronics |

|

$550 |

Telecom |

|

$480 |

Packaging |

|

$450 |

U.S. Chemical |

|

$460 |

Plastics |

|

$182 |

Apparel |

|

$180 |

Pharmaceutical |

|

$165 |

Tobacco |

|

$100 |

Semiconductor |

|

$92 |

Hospitality / Restaurant |

|

$90 |

US Insurance |

|

$83 |

Printing |

|

$80 |

Corrosion Removal |

|

$57 |

US Steel |

|

$43 |

Newspaper |

|

$42 |

Diet Supplement |

|

$40 |

Diet |

|

$32 |

Publishing |

|

$30 |

Catalysts |

|

$27 |

Glass |

|

$24 |

Advertising |

|

$18 |

Cosmetics |

|

$13 |

Chocolate |

|

$10 |

Battery |

|

$5 |

Blue Jeans |

|

$4 |

Khakis |

|

$2.8 |

Fluorescent Tagging |

|

|

NanoNews-Now

Editorial Calendar |

|

Jun '04 |

Tools |

|

Jul '04 |

Memory & Chip Technology |

|

Aug '04 |

Jobs |

|

Sep '04 |

Life Extension |

|

Oct '04 |

Space Elevator |

|

Nov '04 |

Investments |

|

Dec '04 |

Self Assembly |

|

Jan '05 |

Patents |

|

|

There are some that argue that investing in nanotechnology startups and small companies is riskier because of the higher probability for hype and incidences of scams. However, this past couple of years it seems evident that the larger more established publicly traded companies, like Tyco, WorldCom, Enron, Parmalat, etc. should be no less exempt from this scrutiny. It is expected that wherever there is major money to be made, there will be hype and scams. This does not mean investors should not invest or be more risk adverse. It just means investors need to be more careful about how they decide to invest and be smarter about it. The desire to make money must be balanced by responsibility and accountability.

It is still the responsibility of the investor to do their due diligence. Many of those problems they came up against during dot.com was the skipping of such important practices believing they would miss the gravy train pulling out of the station without them before finishing their due diligence. Some of it can certainly be because these investors did not understand these businesses.

Of course, it is also the responsibility of the entrepreneur seeking to raise funding to present their business model and case in a way that will make the investor understand their value proposition. In the end, the onus is on the entrepreneur since they are the ones who are asking for the money and the investor is the one who has it to give. The entrepreneur must persuade and convince the investor why they should be given the money they seek and how they will create an attractive return to their investor. Some investors will be easier to convince than others depending on their expertise. Not all investors will want to invest even if it is a good argument. There will be many reasons why an investor will not invest even if it is a convincing argument and good business plan. Sometimes it is just not a good fit in which case you should move on to the next potential investor.

An interesting argument is that entrepreneurs cannot be trusted because of what happened during dot.com. Giving several million dollars to someone in their mid-20's with little business experience to head an internet startup and then expecting them to be responsible with spending may be construed by some as naÔve. Many of those young entrepreneurs, even though they may have had a great business idea, had little experience managing money. Even parents manage their children's allowance spending to some degree and the deal in some households is that chores are often done in exchange for the allowance.

Recently, a good friend of mine sent me this article from a Human Resources trade magazine (Personnel Today, Feb. 24, 2004). In a nutshell, a few years back a consulting group did research on charting the differences between successful entrepreneurs and chief executives. In some key areas, such as drive, determination and working long hours, there was little difference between the two groups. Interestingly enough, where entrepreneurs really outscored executives was in integrity. Some 70 per cent of those who successfully started their own businesses have 'an honest, ethical style of leadership', compared with 28 per cent of chief executives. The details of how the study was conducted and the definitions of what constitutes an 'an honest, ethical style of leadership' were not provided but the numbers are striking and worth commenting on.

It seems that when the article mentions chief executives they are referring to those of large corporations. Are entrepreneurs really different from 'normal' manager-executives? Perhaps they are not different but just used to a certain corporate culture. However, most entrepreneurs have rejected the corporate culture the chief executives have accepted. Does this mean that entrepreneurs are more trustworthy than chief executives? Probably not if they are from the other 30% pool.

According to the article, some believe there are two very distinct types of entrepreneur - 'one-man bands', who become larger-than-life heads of the organization, and those who delegate and create much bigger organizations. One of the characteristics of entrepreneurs is that they are self-centered and often arrogant. They like being in control, and they are often entrepreneurs because they couldn't stand working for other people. This may be true in many cases but this is not necessarily a bad thing if one knows how to manage them.

The same article states that in their desire to get results, entrepreneurs will encourage others to be like them and take the initiative. They are three times more likely to do so than CEOs, who are more likely to be interested in keeping the team on an even keel and creating harmony than in pushing on. The latter approach may not be appropriate for a startup strategy that requires quick thinking and decision making versus consensus and maintaining the status quo. A major difference between companies run by entrepreneurs and others is the shorter decision time, which generates a more active culture. In a large company, what could have taken months going through various committees and accounting reports, can be decided in days.

A couple of reasons pointed out in the article why entrepreneurial ventures may be more ethical is that in a startup, it works because the entrepreneurs choose self-starters who believe in what they are doing and can work on their own. Being honest with your employees is extremely important to maintain the 'band of brothers' mentality taking on the world that is necessary in the very early lean years of a startup. This honesty generates a high-standards culture where people believe they will be treated well and fairly, and just as importantly, their individual contribution will be recognized and rewarded. The downside of this integrity is that poor performance is also recognized and punished. The upside is that in a small organization, you are likely to be given a lot more responsibility and experience, which can be traded elsewhere if need be.

As a company grows, it's structure will have to change to accommodate growth. As a company grows, it is natural to start seeing the entrepreneurial spirit become diluted with every infusion of new people. From the long time New York Times Bestsellers list, "The Tipping Point", by Malcolm Gladwell, once an organization starts to reach approximately 150 (the magic number that is some critical threshold) people, something goes.

The idea is investors do need to screen and interview the management teams extensively for any potential management issues. For this reason, many investors prefer to see a management team in a startup with extensive management experience with regard to budgets, planning, operations, and finance. I have noted in the January 2004 article that it is not necessarily a good thing to hire someone with an impressive and extensive corporate experience even though it may give some investors the "warm and fuzzies". You also do not want to hire failed startup entrepreneurs, unless you can be certain they learned their lessons from the failure.

It is also important to understand what makes up good management teams first. The leader and the manager are not necessarily the same person although they can be. One inspires and looks at the big picture, and the other makes sure the results come in on time and within budget. The answer is not to just hire experienced members to avoid this nor is the answer to stick to teams of purely entrepreneurs to avoid the other 72% of chief executives. There is no magic bullet to substitute for asking the right questions and performing proper due diligence like background checks. That is the only way to avoid throwing out the baby with the bath water.

Of course it is not a good idea to make generalizations about entrepreneurs and chief executives as did the article. The point is that investors need to play a more active role in monitoring and managing those companies in which they invest.

Stay tuned for next month's article.

|

Dr. Pearl Chin has an MBA from Cornell, a Ph.D. in Materials Science and Engineering from University of Delaware's Center for Composite Materials and B.E. in Chemical Engineering from The Cooper Union.

Dr. Chin specializes in advising on nanotechnology investment opportunities. She is also CEO of Red Seraphim Consulting where she advises investment firms and startup firms on the business strategy of nanotechnology investments. She was Managing Director of the US offices and co-Managing Director of the London offices of Cientifica. Prior to that, she was a Management Consultant with Pittiglio Rabin Todd & McGrath (PRTM)'s Chemicals, Engineered Materials and Packaged Goods group.

Dr. Chin will be advising the Cornell University JGSM's student run VC fund, Big Red Venture Fund (BRVF), on investing in nanotechnology.

She is a Senior Associate of The Foresight Institute in the US and was the US Representative of the Institute of Nanotechnology in the UK. She was an alternate finalist for a Congressional Fellowship with the Materials Research Society.

She was also a Guest Scientist collaborating with the National Institute of Standards & Technology (NIST) Polymer Division's Electronic Materials Group under the US Department of Commerce.

Dr. Chin is a US Citizen born and raised in New York City.

She can be contacted here.

|

Nanotubes and the tale of the rats

|

|

Reprinted with permission from Howard Lovy's NanoBot, January 08, 2004, (link)

A Reuters report on how nanotubes will kill you (if you're a rat) was a prelude to Nanotox 2004 next week in the U.K. The news conference was a way to generate some media buzz in advance and get reporters all jazzed up over an event at the Royal Microscopical Society. Of course, Small Times' man in London will be there, so you can expect some first-rate reporting, with proper context.

The British scientists, meanwhile, were telling rat tales, pointing to DuPont toxicologist David Warheit's recent study on the toxicity of single-wall carbon nanotubes in rats.

Yes, it's DuPont that did the study, so you can read what you want into it, but the Center for Biological and Environmental Nanotechnology (CBEN) at Rice University had also looked at the results.

I'll cut to the chase on the tale of the rats. The study concludes, in part:

"Exposures to high-dose (5 mg/kg) SWCNT produced mortality in ~15% of the SWCNT-instilled rats within 24 h postinstillation. This mortality resulted from mechanical blockage of the upper airways by the instillate and was not due to inherent pulmonary toxicity of the instilled SWCNT particulate."

Kevin Ausman CBEN's executive director, supplied me with a wonderfully understandable translation during a conversation I had with him a month ago in Chicago:

What that means is that if you look at just the cross-sections of the lungs, "Uh-oh. Bad things are happening." If you look at the biochemistry of what's going, almost nothing seems to be going on. And so the normal biochemical tags for, "something bad is happening" aren't telling something bad is happening."

Here's my translation of the translation: The rats were definitely dead (and I believe they are still dead, although I have yet to confirm this). The nanotubes were definitely the guilty party. But the late rodents met their rat makers by suffocation, and not necessarily from any poison in the tiny tubes.

Plus, what the researchers did, as Ausman explained it to me, was basically disperse the nanotubes into a soap-and-water solution and inject it into the lungs, avoiding the whole issue of how the nanotubes ever got there in the first place.

This is how science works. Small steps, each study building on the conclusions of others. Nanotubes might, as the slogan goes these days, turn out to be the "next asbestos," but it is far too early to convict them of anything except being in the wrong rats at the wrong time.

For more on DuPont and nanotubes, here's an excellent report from The News Journal of Delaware. And more background can be found on Small Times here and here.

Nano is a concept by which we measure our pain

Reprinted with permission from Howard Lovy's NanoBot, March 28, 2004, (link)

Toxicologist Eva Oberdorster's new study on the effects of nanoparticles on aquatic animals deserves some thoughtful analysis, yet the Washington Post makes some strange leaps of logic in its reporting.

The study, described at a scientific meeting Sunday, was small and has yet to be peer reviewed or published in a scientific journal. And although some companies anticipate making tons of the particles within the next few years, current production levels are relatively low, so the risk of exposure for humans and other animals is still quite small.

Nonetheless, the findings underscore the growing recognition that the hot new field of nanotechnology, which federal officials have said will be at the heart of America's "next industrial revolution," may bring with it a number of old-fashioned trade-offs in terms of potential environmental damage and health risks.

Other animal studies have already suggested that a related class of nanoparticles cause lung injuries when inhaled, raising concerns about worker safety in the small but growing number of nanoparticle factories.

Sorry, but the qualifiers "may" and "suggested" just do not do enough to counteract the impression left on the reader that nanoparticles cause lung injuries and threaten factory workers.

As I've pointed out before, the "animal studies" mentioned above concluded that if you pump rats' lungs full of nanotubes, they will suffocate. The toxicity of the nanoparticles was not conclusive and, in fact, it was suggested that the clumping was a good sign, since it prevented the nanotubes from reaching deeper into the lungs.

The vague idea of some future "factory workers" being endangered is mentioned once, then dropped.

While it would be foolish for nanotech businesses and advocates in government to dismiss concerns over "nanotox," all parties need to stick to the evidence as it's presented. This latest study is yet another small piece of evidence in a longer process of scientific discovery. Despite the tendency of the media to want to tell its readers what these small-scale studies mean by making all sorts of unscientific leaps in logic for them, don't lose sight of what is actually being presented.

Some better context can be found in The New York Times' coverage:

"This is a yellow light, not a red one," Dr. Oberdorster said in a telephone interview last week.

Vicki L. Colvin, whose laboratory at Rice University's Center for Biological and Environmental Nanotechnology supplied the buckyballs used by Dr. Oberdorster, was even more cautious about the results, which have not yet been reviewed by other scientists.

Dr. Colvin said that the surface characteristics of the lab's buckyballs, which are not a form that is commercially available, needed further study. She said that they had not been coated, a process that is commonly used to limit the toxicity of such materials in applications like drug delivery.

Nanotechnology is such a young discipline that any issue for which the nano name is invoked is largely a reflection of a personal worldview or political agenda rather than any overwhelming body of evidence. Nanotechnology advocates in business and government choose to focus on the optimistic leaps of logic, while those who see corporate conspiracies in the wallpaper can make just as many plausible or implausible leaps into the negative. As I told Neofiles a few months ago:

A health advocate could say that once nanoparticles breach the blood-brain barrier, we're entering into dangerous territory, while another can say that breaching that barrier will enable a range of cures for various brain disorders. Nanotechnology, right now, is an unsettled wilderness that is either abundant with resources for the picking, or a vast frozen wasteland. It's a reflection of your own worldview.

Right now, the general public is being bombarded with some amazing predictions of how nanotechnology will completely alter almost every aspect of their lives. To many, the claims seem not only fantastic, but implausible. Nanotech proponents in government and business are just as guilty of promoting selective logic as the neoluddites of the environmental movement when they ask the public to believe positive implausible scenarios and not to pay attention to the negative.

It's a difficult concept to describe. I was asked by a reporter for NPR's "Marketplace" last week to define nanotechnology. I gave the usual explanation (under-100-nanometers, special-properties, etc.), and then I struggled to explain how nanotechnology right now is more of a concept than anything else. We've created the building blocks and dumped them on the floor. What we create with them now, and how safely we do it, is yet to be determined.