Home > Press > SUTD developed a simple method to print planar microstructures of polysiloxane: The new method, embedded ink writing (EIW), enables direct writing of polysiloxane which helps in the fabrication of microfluidic devices, flexible wearables, and soft actuators

|

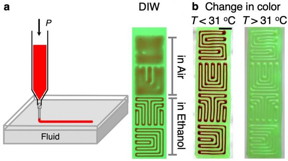

| Concept of embedded ink writing (EIW). A polysiloxane ink is printed by a direct ink writing (DIW) 3D printer in Newtonian fluids as embedding media. The surrounding liquid media allow the inks to maintain larger contact angles (> 100o) on the substrates. Inks for EIW can be functionalized by suspending functional microparticles (e.g., embedding thermochromic leuco dye microparticles). CREDIT SUTD |

Abstract:

Polysiloxane is an elastic polymer which is widely used in fluidics, optics, and biomedical engineering. It offers desirable properties for microfabrication due to its castable and curable properties.

SUTD developed a simple method to print planar microstructures of polysiloxane: The new method, embedded ink writing (EIW), enables direct writing of polysiloxane which helps in the fabrication of microfluidic devices, flexible wearables, and soft actuators

Singapore | Posted on May 29th, 2020To produce small scale structures consisting of polysiloxane, soft lithography is used as a standard technique in academic research laboratories.

Recent advances in digital fabrication, in particular 3D printing, have enabled direct patterning of polysiloxane albeit with strict requirements for the properties of the printing inks. Suitable inks are usually highly viscous and fast-curing. For 3D printing, the yield stress or photocurable characteristics of the polysiloxane resins are required to allow them to retain the printed shape.

The low viscosity of the additive-curing polysiloxane makes them incompatible for printing with direct ink writing (DIW) 3D printers. While the low viscosity of the polysiloxane resin such as Sylgard 184 facilitates easy extrusion through the nozzles, the reflow of the patterned resin can compromise the print fidelity.

Researchers from Singapore University of Technology and Design's (SUTD) Soft Fluidics Lab developed a simple method to fabricate reproducible planar microstructures consisting of polysiloxane using commercially available liquid polysiloxane resins without changing their properties.

In this newly developed approach, curable liquid polysiloxane with the viscosity in the range of 1-100 Pa.s was dispensed in a liquid immiscible with the resins such as methanol, ethanol, and isopropanol. The contact angle of the dispensed polysiloxane on the substrate increased from 20o in the air to 100o in alcohols. The increase in the contact angles allowed maintaining the structures of patterned polysiloxane until curing, after which the embedding liquid was readily removed by evaporation. The method was termed as embedded ink writing (EIW) (refer to image).

"With EIW, polysiloxane inks can be patterned on different soft and rigid substrates without compromising the adhesion of the printed polysiloxane with the substrate," explained lead author Dr. Rahul Karyappa from SUTD.

"The presence of embedding media did not hamper the bonding of the polysiloxane filaments in both lateral and vertical arrangements, allowing this technology to be effective especially in fabricating flexible devices and microfluidic devices using commercially available PDMS resin," added principal investigator, Assistant Professor Michinao Hashimoto from SUTD.

###

The research work was published in ACS Applied Materials and Interfaces, a leading journal that encourages newly-discovered materials and interfacial processes. Terry Ching, a PhD scholar at SUTD, also participated in this research project.

####

For more information, please click here

Contacts:

Jessica Sasayiah

656-499-4823

Copyright © Singapore University of Technology and Design

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Microfluidics/Nanofluidics

![]() Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

Projecting light to dispense liquids: A new route to ultra-precise microdroplets January 30th, 2026

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

Flexible Electronics

![]() MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

MXene nanomaterials enter a new dimension Multilayer nanomaterial: MXene flakes created at Drexel University show new promise as 1D scrolls January 30th, 2026

![]() Flexible electronics integrated with paper-thin structure for use in space January 17th, 2025

Flexible electronics integrated with paper-thin structure for use in space January 17th, 2025

![]() Beyond wires: Bubble technology powers next-generation electronics:New laser-based bubble printing technique creates ultra-flexible liquid metal circuits November 8th, 2024

Beyond wires: Bubble technology powers next-generation electronics:New laser-based bubble printing technique creates ultra-flexible liquid metal circuits November 8th, 2024

Wearable electronics

![]() Breakthrough brings body-heat powered wearable devices closer to reality December 13th, 2024

Breakthrough brings body-heat powered wearable devices closer to reality December 13th, 2024

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||