Home > Press > Erasable ink for 3-D printing: Laser-written three-dimensional microstructures can be erased and rewritten, if desired -- very important paper publication in Angewandte Chemie

|

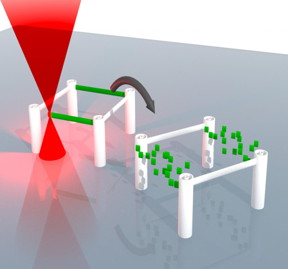

| 3-dimensional microstructures can be written using a laser, erased, and rewritten. CREDIT (Photo: KIT) |

Abstract:

3D printing by direct laser writing produces micrometer-sized structures with precisely defined properties. Researchers of Karlsruhe Institute of Technology (KIT) have now developed a method to erase the ink used for 3D printing. In this way, the small structures of up to 100 nm in size can be erased and rewritten repeatedly. One nanometer corresponds to one millionth of a millimeter. This development opens up many new applications of 3D fabrication in biology or materials sciences, for instance.

Erasable ink for 3-D printing: Laser-written three-dimensional microstructures can be erased and rewritten, if desired -- very important paper publication in Angewandte Chemie

Karlsruhe, Germany | Posted on May 2nd, 2017Direct laser writing means that a computer-controlled, focused laser beam generates the structure in a photoresist similar to a pen. "Developing an ink that can be erased again was one of the big challenges in direct laser writing," Professor Christopher Barner-Kowollik of KIT's Institute for Chemical Technology and Polymer Chemistry says. The scientists have now met with success: They have developed an ink with reversible bonding, the building blocks of which can be separated from each other. The printed structure is simply erased by immersing it into a chemical solvent. At the point of erasure, a new structure can be written. In this way, the structure can be modified repeatedly.

The process was developed in close cooperation with the group of Professor Martin Wegener at the Institute of Applied Physics and the Institute of Nanotechnology of KIT. The physicists developed highly specialized 3D printers that produce scaffolds of up to 100 nm in size by direct laser writing.

"The ink with defined breaking points can be used for a variety of applications," doctoral student and first author Markus Zieger says. Structures written with erasable ink can be integrated into structures made of non-erasable ink: Support constructions can be produced by 3D printing, which are similar to those used when building bridges and removed later on. It is also possible to further develop 3D designer petri dishes for use in biology. Recently, such structures were designed by KIT to grow cell cultures in three dimensions on the laboratory scale. "During cell growth, parts of the 3D microscaffold could be removed again to study how the cells react to the changed environment," Martin Wegener explains. According to the scientists, it is also feasible to produce reversible wire bonds from erasable conducting structures in the future. A permanent ink can be mixed with a non-permanent ink to influence the properties of the printed material and make it more or less porous, for instance.

The new process is presented in the renowned journal Angewandte Chemie under the heading "Cleaving Direct Laser Written Microstructures on Demand." The reviewers rated this publication a "very important paper." 3D printing already is indispensable in many fabrication areas. Its importance is increasing. "According to estimations, some 10 percent of all goods will be produced by 3D printing in 2030," Barner-Kowollik and Wegener say.

###

Markus M. Zieger, Patrick Mueller, Alexander S. Quick, Martin Wegener, Christopher Barner-Kowollik: Cleaving Direct Laser Written Microstructures on Demand. Angewandte Chemie 2017, 129, 1-6; DOI: 10.1002/anie.201701593

####

About Karlsruhe Institute of Technology (KIT)

Karlsruhe Institute of Technology (KIT) pools its three core tasks of research, higher education, and innovation in a mission. With about 9,300 employees and 25,000 students, KIT is one of the big institutions of research and higher education in natural sciences and engineering in Europe.

KIT - The Research University in the Helmholtz Association

For more information, please click here

Contacts:

Monika Landgraf

49-721-608-47414

Kosta Schinarakis

Themenscout

Tel.: +49 721 608-41956

Fax: +49 721 608-43568

Copyright © Karlsruhe Institute of Technology (KIT)

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Photonics/Optics/Lasers

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||