Home > Press > Scientists develop way to upsize nanostructures into light, flexible 3-D printed materials: Virginia Tech, Livermore National Lab researchers develop hierarchical 3-D printed metallic materials

|

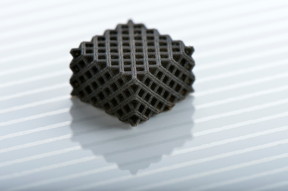

| A new process allows materials synthesized at the nano-level to be scaled to larger sizes to take advantage of their mechanical, optical, and energy properties. Xiaoyu "Rayne" Zheng, assistant professor of mechanical engineering, describes the process in the journal Nature Materials.

Credit: Virginia Tech |

Abstract:

For years, scientists and engineers have synthesized materials at the nanoscale level to take advantage of their mechanical, optical, and energy properties, but efforts to scale these materials to larger sizes have resulted in diminished performance and structural integrity.

Scientists develop way to upsize nanostructures into light, flexible 3-D printed materials: Virginia Tech, Livermore National Lab researchers develop hierarchical 3-D printed metallic materials

Blacksburg, VA | Posted on July 20th, 2016Now, researchers led by Xiaoyu "Rayne" Zheng, an assistant professor of mechanical engineering at Virginia Tech have published a study in the journal Nature Materials that describes a new process to create lightweight, strong and super elastic 3-D printed metallic nanostructured materials with unprecedented scalability, a full seven orders of magnitude control of arbitrary 3-D architectures.

Strikingly, these multiscale metallic materials have displayed super elasticity because of their designed hierarchical 3-D architectural arrangement and nanoscale hollow tubes, resulting in more than a 400 percent increase of tensile elasticity over conventional lightweight metals and ceramic foams.

The approach, which produces multiple levels of 3-D hierarchical lattices with nanoscale features, could be useful anywhere there's a need for a combination of stiffness, strength, low-weight, high flexibility -- such as in structures to be deployed in space, flexible armors, lightweight vehicles and batteries, opening the door for applications in aerospace, military and automotive industries.

Natural materials, such as trabecular bone and the toes of geckoes, have evolved with multiple levels 3-D architectures spanning from the nanoscale to the macroscale. Human-made materials have yet to achieve this delicate control of structural features.

"Creating 3-D hierarchical micro features across the entire seven orders of magnitude in structural bandwidth in products is unprecedented," said Zheng, the lead author of the study and the research team leader. "Assembling nanoscale features into billets of materials through multi-leveled 3-D architectures, you begin to see a variety of programmed mechanical properties such as minimal weight, maximum strength and super elasticity at centimeter scales."

The process Zheng and his collaborators use to create the material is an innovation in a digital light 3-D printing technique that overcomes current tradeoffs between high resolution and build volume, a major limitation in scalability of current 3-D printed microlattices and nanolattices.

Related materials that can be produced at the nanoscale such as graphene sheets can be 100 times stronger than steel, but trying to upsize these materials in three dimensions degrades their strength eight orders of magnitude - in other words, they become 100 million times less strong.

"The increased elasticity and flexibility obtained through the new process and design come without incorporating soft polymers, thereby making the metallic materials suitable as flexible sensors and electronics in harsh environments, where chemical and temperature resistance are required," Zheng added.

These multi-leveled hierarchical lattice also means more surface area is available to collect photons energies as they can enter the structure from all directions and be collected not just on the surface, like traditional photovoltaic panels, but also inside the lattice structure. One of the great opportunities this study creates is the ability to produce multi-functional inorganic materials such as metals and ceramics to explore photonic and energy harvesting properties in these new materials

Besides Zheng, team members include Virginia Tech graduate research students Huachen Cui and Da Chen from Zheng's group, and colleagues from Lawrence Livermore National Laboratory. The research was conducted under the Department of Energy Lawrence Livermore Laboratory-directed research support with additional support from Virginia Tech, the SCHEV fund from the state of Virginia, and the Defense Advanced Research Projects agency.

####

For more information, please click here

Contacts:

Lindsey Haugh

540-231-2476

Copyright © Virginia Tech

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Laboratories

![]() Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

Researchers develop molecular qubits that communicate at telecom frequencies October 3rd, 2025

![]() A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

A battery’s hopping ions remember where they’ve been: Seen in atomic detail, the seemingly smooth flow of ions through a battery’s electrolyte is surprisingly complicated February 16th, 2024

3D & 4D printing/Additive-manufacturing

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

Fiber sensing scientists invent 3D printed fiber microprobe for measuring in vivo biomechanical properties of tissue and even single cell February 10th, 2023

![]() 3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

3D-printed decoder, AI-enabled image compression could enable higher-res displays December 9th, 2022

![]() Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Researchers design new inks for 3D-printable wearable bioelectronics: Potential uses include printing electronic tattoos for medical tracking applications August 19th, 2022

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Molecular Nanotechnology

![]() Quantum pumping in molecular junctions August 16th, 2024

Quantum pumping in molecular junctions August 16th, 2024

![]() Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

Scientists push the boundaries of manipulating light at the submicroscopic level March 3rd, 2023

![]() First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

First electric nanomotor made from DNA material: Synthetic rotary motors at the nanoscale perform mechanical work July 22nd, 2022

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Photonics/Optics/Lasers

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||