Home > Press > Thin coating on condensers could make power plants more efficient: Graphene layer one atom thick could quadruple rate of condensation heat transfer in generating plants

|

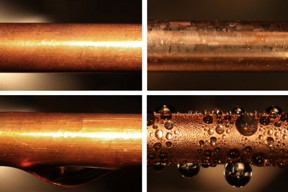

| An uncoated copper condenser tube (top left) is shown next to a similar tube coated with graphene (top right). When exposed to water vapor at 100 degrees Celsius, the uncoated tube produces an inefficient water film (bottom left), while the coated shows the more desirable dropwise condensation (bottom right).

Courtesy of the researchers |

Abstract:

ost of the world's electricity-producing power plants -- whether powered by coal, natural gas, or nuclear fission -- make electricity by generating steam that turns a turbine. That steam then is condensed back to water, and the cycle begins again.

Thin coating on condensers could make power plants more efficient: Graphene layer one atom thick could quadruple rate of condensation heat transfer in generating plants

Cambridge, MA | Posted on June 1st, 2015But the condensers that collect the steam are quite inefficient, and improving them could make a big difference in overall power plant efficiency.

Now, a team of researchers at MIT has developed a way of coating these condenser surfaces with a layer of graphene, just one atom thick, and found that this can improve the rate of heat transfer by a factor of four -- and potentially even more than that, with further work. And unlike polymer coatings, the graphene coatings have proven to be highly durable in laboratory tests.

The findings are reported in the journal Nano Letters by MIT graduate student Daniel Preston, professors Evelyn Wang and Jing Kong, and two others. The improvement in condenser heat transfer, which is just one step in the power-production cycle, could lead to an overall improvement in power plant efficiency of 2 to 3 percent based on figures from the Electric Power Research Institute, Preston says -- enough to make a significant dent in global carbon emissions, since such plants represent the vast majority of the world's electricity generation. "That translates into millions of dollars per power plant per year," he explains.

There are two basic ways in which the condensers -- which may take the form of coiled metal tubes, often made of copper -- interact with the flow of steam. In some cases, the steam condenses to form a thin sheet of water that coats the surface; in others it forms water droplets that are pulled from the surface by gravity.

When the steam forms a film, Preston explains, that impedes heat transfer -- and thus reduces the efficiency -- of condensation. So the goal of much research has been to enhance droplet formation on these surfaces by making them water-repelling.

Often this has been accomplished using polymer coatings, but these tend to degrade rapidly in the high heat and humidity of a power plant. And when the coatings are made thicker to reduce that degradation, the coatings themselves impede heat transfer.

"We thought graphene could be useful," Preston says, "since we know it is hydrophobic by nature." So he and his colleagues decided to test both graphene's ability to shed water, and its durability, under typical power plant conditions -- an environment of pure water vapor at 100 degrees Celsius.

They found that the single-atom-thick coating of graphene did indeed improve heat transfer fourfold compared with surfaces where the condensate forms sheets of water, such as bare metals. Further calculations showed that optimizing temperature differences could boost this improvement to 5 to 7 times. The researchers also showed that after two full weeks under such conditions, there was no measurable degradation in the graphene's performance.

By comparison, similar tests using a common water-repelling coating showed that the coating began to degrade within just three hours, Preston says, and failed completely within 12 hours.

Because the process used to coat the graphene on the copper surface -- called chemical vapor deposition -- has been tested extensively, the new method could be ready for testing under real-world conditions "in as little as a year," Preston says. And the process should be easily scalable to power plant-sized condenser coils.

###

The research team also included MIT postdoc Daniela Mafra and former postdoc Nenad Miljkovic, who is now an assistant professor at the University of Illinois at Urbana-Champaign. The work was supported by the Office of Naval Research and the National Science Foundation.

####

For more information, please click here

Contacts:

Andrew Carleen

617-253-1682

Copyright © Massachusetts Institute of Technology

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Govt.-Legislation/Regulation/Funding/Policy

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() New imaging approach transforms study of bacterial biofilms August 8th, 2025

New imaging approach transforms study of bacterial biofilms August 8th, 2025

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Military

![]() Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

Quantum engineers ‘squeeze’ laser frequency combs to make more sensitive gas sensors January 17th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Single atoms show their true color July 5th, 2024

Single atoms show their true color July 5th, 2024

![]() NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

NRL charters Navy’s quantum inertial navigation path to reduce drift April 5th, 2024

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||