Home > Press > Inkjet printing process for kesterite solar cells

|

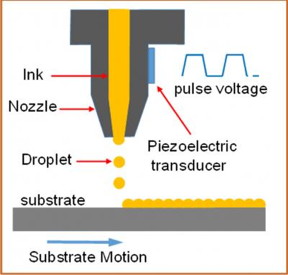

| This is an illustration of the working principle of inkjet printing. CREDIT: HZB |

Abstract:

The drop-on-demand inkjet printing is a promising approach allowing patterning of materials with negligible materials waste; hence, significant reduction of raw materials cost can be achieved. Furthermore, inkjet printing can be easily adapted to a roll-to-roll process, which is suitable for large scale production. From the industrial application perspective, both of these two features of the inkjet printing technology are of great interest. A critical requirement for using inkjet printing is to develop a suitable ink in terms of viscosity and stability which leads to compact and homogeneous films.

Inkjet printing process for kesterite solar cells

Berlin, Germany | Posted on May 6th, 2015Tuning the molecular ink

Dr. Xianzhong Lin from the Institute for Heterogeneous Material Systems of HZB used a molecular ink which was originally developed for spin coating technologies. The ink is produced by dissolving Cu, Zn, Sn metal salt and thiourea in dimethyl sulfoxide solvent. Lin tested its suitability for inkjet printing. He found that the viscosity of the ink can be tuned by adjusting the ink concentration and the ink composition can also be easily controlled by adding or reducing the amount of each chemical added. The CZTSSe absorbers were formed by annealing the inkjet-printed Cu-Zn-Sn-S precursor film under an atmosphere containing Selenium.

Economical process

Initial optimization of the processing conditions such as ink composition and printing parameters have already yielded solar cells with efficiencies up to 6.4 %. The huge advantage of inkjet printing versus spin coating to obtain thin film absorbers is the lesser amount of waste: Whereas with spin coating, a large quantity of the ink material is wasted, the inkjet printing is very economical: For example, less than 20 microliter ink is needed to build up a micrometer CZTSSe thin film absorber on an inch by inch substrate in this study.

Low toxicity and low waste

"Although the solar cell performance is still far below the record efficiency of 12.7 % for CZTSSe based solar cells, the great advantage of our approach is the low toxic and low material wastage process", Prof. Martha Lux-Steiner explains. The team is now working on the optimization of processing conditions for the kesterite absorbers to further improve the solar cell performance and on the deposition of buffer and TCO layers by inkjet printing. The goal is to print a complete device with high efficiency without relying on expensive vacuum technology. This work opens up a promising route for the fabrication of kesterite thin film solar cells.

####

For more information, please click here

Contacts:

Dr. Antonia Rötger

Copyright © Helmholtz-Zentrum Berlin für Materialien und Energie

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Interviews/Book Reviews/Essays/Reports/Podcasts/Journals/White papers/Posters

![]() Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

Metasurfaces smooth light to boost magnetic sensing precision January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Energy

![]() Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

Sensors innovations for smart lithium-based batteries: advancements, opportunities, and potential challenges August 8th, 2025

![]() Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Simple algorithm paired with standard imaging tool could predict failure in lithium metal batteries August 8th, 2025

Solar/Photovoltaic

![]() Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

Spinel-type sulfide semiconductors to operate the next-generation LEDs and solar cells For solar-cell absorbers and green-LED source October 3rd, 2025

![]() KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

KAIST researchers introduce new and improved, next-generation perovskite solar cell November 8th, 2024

![]() Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

Groundbreaking precision in single-molecule optoelectronics August 16th, 2024

![]() Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Development of zinc oxide nanopagoda array photoelectrode: photoelectrochemical water-splitting hydrogen production January 12th, 2024

Printing/Lithography/Inkjet/Inks/Bio-printing/Dyes

![]() Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

Presenting: Ultrasound-based printing of 3D materials—potentially inside the body December 8th, 2023

![]() Simple ballpoint pen can write custom LEDs August 11th, 2023

Simple ballpoint pen can write custom LEDs August 11th, 2023

![]() Disposable electronics on a simple sheet of paper October 7th, 2022

Disposable electronics on a simple sheet of paper October 7th, 2022

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||