Home > Press > Graphene-Toughened Composites – A Milestone for Next Generation Aerospace Structures? Plasma functionalisation technology produces significant improvements in mechanical performance and damage tolerance in carbon fibre composites

|

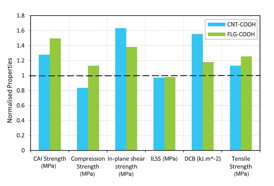

| Effect of Haydale functionalised additions on mechanical performance of carbon fibre-epoxy composite |

Abstract:

The School of Engineering at Cardiff University and Haydale have announced new research demonstrating significant improvements in mechanical performance including impact resistance in carbon fibre composites.

Graphene-Toughened Composites – A Milestone for Next Generation Aerospace Structures? Plasma functionalisation technology produces significant improvements in mechanical performance and damage tolerance in carbon fibre composites

South Wales, UK | Posted on November 11th, 2014These results, particularly the increased damage tolerance, could have significant implications for the development of future composite structures, demonstrating the potential in future aircraft design for weight saving and the consequent environmental benefits such as reductions in CO2 emissions.

The research was undertaken by the Cardiff School of Engineering with additional funding from the European Community's Seventh Framework programme under the Clean Sky Joint Technology Initiative. The Clean Sky Initiative is one of the largest existing European research programmes with the aim of accelerating technological advancements in aircraft design and green aviation technology. The project was based on requirements specified by the Centro Italiano Richerche Aerospaziale (CIRA) for developing new composite technologies for Green Regional Aircraft (GRA), and was managed by an integrated team from CIRA, Cardiff School of Engineering and Haydale.

The research investigated graphene nanoplatelet (GNP) and carbon nanotube (CNT) reinforcement technology. Compared to a resin, a macro reinforcement such as carbon fibre is immensely stiff and strong, and hence in a fibre-reinforced composite, the properties are dominated by the fibre. The addition of functionalised graphene to neat resin has been shown to result in a doubling in stiffness, but the effect of this in a macrocomposite would normally be expected to be much less. The results observed in this research show a 13% increase in compression strength and a 50% increase in compression after impact performance, indicating that fracture mode has been positively influenced. This is a significant result as damage resistance and compression properties are of paramount importance in high performance structures such as composite aircraft wings.

A resin infusion technique was employed to produce composites containing a small percentage of nanomaterials, achieving maximum material improvements. This technique is used widely in aerospace and other high performance engineering industries for cost effective manufacture of high integrity materials. Significantly, the nanomaterials were surface treated using Haydale's low temperature, low energy HDPlas® plasma process, which promotes homogenous dispersion and chemical bonding and avoids the waste streams produced by traditional functionalisation processes.

Ray Gibbs, CEO of Haydale commented; "These exceptional results underline the potential of Haydale's tailored, plasma functionalisation process in delivering a scalable technology for the production of superior composites. We believe that by working closely with the Cardiff School of Engineering, our combined resources and expertise can significantly accelerate graphene optimisation and advance greener, more efficient technologies. Nano-reinforced composites offer an extremely promising route to harnessing the superior material properties offered by graphene technology, and this research demonstrates the considerable improvements that can be made to composites by utilising plasma functionalised nano-carbon materials."

Professor Sam Evans from the School of Engineering, Cardiff University, commented: "This research represented a fantastic opportunity for the team at Cardiff to work with frontline graphene materials and technology. We are very excited about contributing to the Clean Sky initiative as it is an extremely ambitious programme and graphene technology has enormous potential for improving the performance of aircraft materials. These initial results suggest that there may be the potential for big weight reductions in aircraft and many other applications, which is very promising."

The potential of graphene in developing a new generation of aerospace structures has taken a significant step forward as a result of the work carried out by Cardiff University. The research leading to these results has received funding from the European Community's Seventh Framework Programme (FP7/2007-2013) for the Clean Sky Joint Technology Initiative under grant agreement n° JTI-CS-2011-2-GRA-01-038. Haydale's surface functionalisation of graphene via its low temperature plasma process has been critical in achieving the considerable material improvements observed in this research. The HDPlas® technique offers significant environmental benefits whilst exploiting the full potential of graphene in composites. Haydale are seeking commercial partners to further develop these highly promising results.

To find out more about Haydale's proprietary plasma process, visit www.haydale.com email or call +44 (0)1269 842946

####

About Haydale Ltd.

Haydale has developed a patent pending proprietary scalable plasma process to functionalise graphene and other nanomaterials. This enabling technology can provide Haydale with a rapid and highly cost efficient method of supplying tailored solutions to enhance applications for both raw material suppliers and product manufacturers.

Functionalisation is carried out through a low pressure plasma process that treats both organic mined fine powder and other synthetically produced nanomaterial powders producing high quality few layered graphenes and graphene nano platelets. The process can functionalise with a range of chemical groups, where the amount of chemicals can be tailored to the customer needs. Good dispersion improves the properties and performance of the host material and ensures it delivers as specified.

The Haydale plasma process does not use wet chemistry, neither does it damage the material being processed, rather it can clean up impurities inherent in the raw material. The technology is a low energy user and most importantly environmentally friendly. The Haydale method is an enabling technology where working with a raw material producer can add value to the base product and tailor the outputs to meet the target applications of the end user.

Haydale, based in South Wales, housed in a purpose built facility for processing and handling nanomaterials with a laboratory facility, is facilitating the application of graphenes and other nanomaterials in fields such as inks, sensors, energy storage, photovoltaics, composites, paints and coatings.

www.haydale.com

About Cardiff University

Cardiff University is recognised in independent government assessments as one of Britain’s leading teaching and research universities and is a member of the Russell Group of the UK’s most research intensive universities. Among its academic staff are two Nobel Laureates, including the winner of the 2007 Nobel Prize for Medicine, University President Professor Sir Martin Evans.

Founded by Royal Charter in 1883, today the University combines impressive modern facilities and a dynamic approach to teaching and research. The University’s breadth of expertise in research and research-led teaching encompasses: the humanities; the natural, physical, health, life and social sciences; engineering and technology; preparation for a wide range of professions; and a longstanding commitment to lifelong learning. Three major new Research Institutes, offering radical new approaches to neurosciences and mental health, cancer stem cells and sustainable places were announced by the University in 2010.

About The Clean Sky Project

Clean Sky is the most ambitious aeronautical research programme ever launched in Europe. Its mission is to develop breakthrough technologies to significantly increase the environmental performances of airplanes and air transport, resulting in less noisy and more fuel efficient aircraft, hence bringing a key contribution in achieving the Single European Sky environmental objectives.

The Clean Sky JTI (Joint Technology Initiative) was born in 2008 and represents a unique Public-Private Partnership between the European Commission and the industry. It is managed by the Clean Sky Joint Undertaking (CSJU) until 31 December 2017.

The CSJU will deliver demonstrators in all segments of civil air transport, grouped into six technological areas called 'Integrated Technology Demonstrators' (ITD).

Further details of The Clean Sky Project can be found at: www.cleansky.eu/

For more information, please click here

Contacts:

James Hayward

(The Scott Partnership)

Tel: +44 (0)1477 539539

Copyright © Haydale Ltd.

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Graphene/ Graphite

![]() Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

Electrifying results shed light on graphene foam as a potential material for lab grown cartilage June 6th, 2025

![]() Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Breakthrough in proton barrier films using pore-free graphene oxide: Kumamoto University researchers achieve new milestone in advanced coating technologies September 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Research partnerships

![]() Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

Lab to industry: InSe wafer-scale breakthrough for future electronics August 8th, 2025

![]() HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

HKU physicists uncover hidden order in the quantum world through deconfined quantum critical points April 25th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||