Home > Press > ‘Nanostitching’ could strengthen airplane skins, more

|

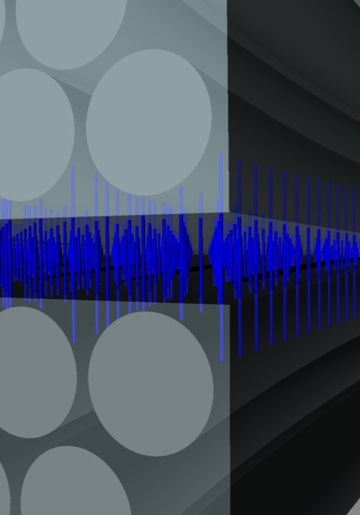

| Schematics showing carbon nanotubes bridging the gap between plies of an advanced composite. CREDIT: Courtesy Wardle lab, MIT |

Abstract:

MIT engineers are using carbon nanotubes only billionths of a meter thick to stitch together aerospace materials in work that could make airplane skins and other products some 10 times stronger at a nominal increase in cost.

‘Nanostitching’ could strengthen airplane skins, more

Cambridge, MA | Posted on March 4th, 2009Moreover, advanced composites reinforced with nanotubes are also more than one million times more electrically conductive than their counterparts without nanotubes, meaning aircraft built with such materials would have greater protection against damage from lightning, said Brian L. Wardle, the Charles Stark Draper Assistant Professor in the Department of Aeronautics and Astronautics.

Wardle is lead author of a theoretical paper on the new nanotube-reinforced composites that will appear in the Journal of Composite Materials (jcm.sagepub.com). He also described the work as keynote speaker at a Society of Plastics Engineers conference this week.

The advanced materials currently used for many aerospace applications are composed of layers, or plies, of carbon fibers that in turn are held together with a polymer glue. But that glue can crack and otherwise result in the carbon-fiber plies coming apart. As a result, engineers have explored a variety of ways to reinforce the interface between the layers by stitching, braiding, weaving or pinning them together.

All of these processes, however, are problematic because the relatively large stitches or pins penetrate and damage the carbon-fiber plies themselves. "And those fiber plies are what make composites so strong," Wardle said.

So Wardle wondered whether it would make sense to reinforce the plies in advanced composites with nanotubes aligned perpendicular to the carbon-fiber plies. Using computer models of how such a material would fracture, "we convinced ourselves that reinforcing with nanotubes should work far better than all other approaches," Wardle said. His team went on to develop processing techniques for creating the nanotubes and for incorporating them into existing aerospace composites, work that was published last year in two separate journals.

How does nanostitching work? The polymer glue between two carbon-fiber layers is heated, becoming more liquid-like. Billions of nanotubes positioned perpendicular to each carbon-fiber layer are then sucked up into the glue on both sides of each layer. Because the nanotubes are 1000 times smaller than the carbon fibers, they don't detrimentally affect the much larger carbon fibers, but instead fill the spaces around them, stitching the layers together.

"So we're putting the strongest fibers known to humankind [the nanotubes] in the place where the composite is weakest, and where they're needed most," Wardle said. He noted that these dramatic improvements can be achieved with nanotubes comprising less than one percent of the mass of the overall composite. In addition, he said, the nanotubes should add only a few percent to the cost of the composite, "while providing substantial improvements in bulk multifunctional properties."

Wardle's co-authors on the Journal of Composite Materials paper are Joaquin Blanco, a visiting graduate student in the Department of Aeronautics and Astronautics, Enrique J. Garcia SM '06, and Roberto Guzman deVilloria, a postdoctoral associate in the department.

This research was sponsored by MIT's Nano-Engineered Composite aerospace STructures (NECST) Consortium ( necst.mit.edu ).

Written by Elizabeth A. Thomson, MIT News Office

####

About MIT

The mission of MIT is to advance knowledge and educate students in science, technology, and other areas of scholarship that will best serve the nation and the world in the 21st century.

For more information, please click here

Contacts:

Elizabeth A. Thomson

MIT News Office

617-258-5402

Copyright © MIT

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Aerospace/Space

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

ICFO researchers overcome long-standing bottleneck in single photon detection with twisted 2D materials August 8th, 2025

![]() Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

Onion-like nanoparticles found in aircraft exhaust May 14th, 2025

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||