Home > Press > Carbon Nanofibers Cut Flammability of Upholstered Furniture

|

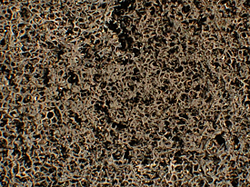

| This microscope image of the remains of upholstery foam with carbon nanofiber additives after a burn test shows that the nanofibers in the foam retained their initial arrangement during the combustion process, forming an insulating structure with an extremely low density. Researchers believe that this “carbon foam” acts as a sponge to absorb the molten foam during burning and to prevent dripping. (Image shows a sample 24 millimeters across.)

Credit: NIST |

Abstract:

Carbon, the active ingredient in charcoal, is normally not considered a fire retardant, but researchers at the National Institute of Standards and Technology (NIST) have determined that adding a small amount of carbon nanofibers to the polyurethane foams used in some upholstered furniture can reduce flammability by about 35 percent when compared to foam infused with conventional fire retardants.

Carbon Nanofibers Cut Flammability of Upholstered Furniture

GAITHERSBURG, MD | Posted on December 9th, 2008Laws require mattresses and upholstered furniture sold in California and used in public spaces such as hotels and offices be treated with fire retardants or barrier fabrics to minimize fire fatalities and injuries and to cut damage costs. According to the National Fire Protection Association, the total burden of fire in the United States was about $270 billion in 2005.

Ten years ago, NIST scientists found that nanoclays could be used as an effective fire retardant additive, but researchers have been seeking alternatives because nanoclay flame retardants do not prevent the melting and dripping of polyurethane foam when exposed to a fire. This molten foam accelerates the burning rate by as much as 300 percent. "It also creates so much smoke that it is a life-safety hazard," said Jeff Gilman, leader of the Materials Flammability Group in the Building and Fire Research Laboratory.

Researchers added carbon nanofibers to the foam because they knew that adding nanoparticles to a polymer normally increases the viscosity, so it doesn't flow as easily. "The carbon nanofibers help prevent the foam from dripping in a pool under the furniture and increasing the fire intensity," Gilman said. Studies of the foam after the experiments showed that carbon nanofibers seemed to create a thermally stable, entangled network that kept the foam from dripping.

NIST fire researchers have traditionally used upholstered furniture to study its flammability, but in this study, they developed a small-scale technique for evaluating the effect of dripping and pooling on foam flammability. About the size of a slice of toast, the foam samples were treated with one of six combinations of carbon nanofibers or conventional clay flame retardants. The foam "toast" was suspended vertically over a pan, ignited, and the amount of drip was measured. The foam with carbon nanofibers did not drip.

"These small-scale experiments correlate well with the fire behavior of larger foam samples and are easier and less expensive to conduct," said Gilman. "The small-scale tests will allow us to cost-effectively perform more experiments and help us find an optimal fire retardant faster."

"Carbon nanofibers are still more expensive than conventional flame retardant materials, but because the price is decreasing and so little needs to be used, they could soon be an affordable and effective option," Gilman explained.

NIST fire scientists will continue to study the mechanisms that reduce flammability and dripping and work with chemical companies, nano-additive suppliers, flame retardant suppliers and foam manufacturers to test new blends of foam and carbon nanofibers to improve flame retardant material. Additionally, new work is planned to develop sustainable, environmentally friendly fire retardants using cellulosic nanofibers and testing other innovative fire retardant approaches.

####

About NIST

Founded in 1901, NIST is a non-regulatory federal agency within the U.S. Department of Commerce. NIST's mission is to promote U.S. innovation and industrial competitiveness by advancing measurement science, standards, and technology in ways that enhance economic security and improve our quality of life.

For more information, please click here

Contacts:

Evelyn Brown

(301) 975-5661

Copyright © NIST

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Home

![]() Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

Nanomaterials enable dual-mode heating and cooling device: Device could cut HVAC energy use by nearly 20% in the US December 2nd, 2020

![]() Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

Bosch Sensortec launches ideation community to foster and accelerate innovative IoT applications : Creativity hub for customers, partners, developers and makers February 18th, 2019

![]() Iran Develops Water-Repellent Nano-Paint December 5th, 2018

Iran Develops Water-Repellent Nano-Paint December 5th, 2018

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||