Home > Press > Metal Foam Has a Good Memory

|

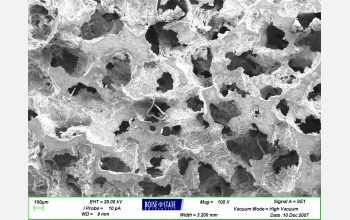

| The porous nature of nickel-manganese-gallium alloy gives it "shape-memory" properties. The material lengthens, or strains, up to 10 percent when subjected to a magnetic field. The NSF-funded researchers believe the porous alloy has great potential for uses that require light weight and a large strain, such as space and automotive applications and tiny motion control devices or biomedical pumps with no moving parts.

Credit: P. Müllner, M. Chmelius and S. Donovan, Boise State University, and D. Dunand and Y. Boonyongmaneerat, Northwestern University. |

Abstract:

Poking holes in magnetic alloy improves its shape-morphing capability

Metal Foam Has a Good Memory

Arlington, VA | Posted on December 20th, 2007In the world of commercial materials, lighter and cheaper is usually better, especially when those attributes are coupled with superior strength and special properties, such as a material's ability to remember its original shape after it's been deformed by a physical or magnetic force.

A new class of materials known as "magnetic shape-memory foams" has been developed by two research teams headed by Peter Müllner at Boise State University and David Dunand at Northwestern University, both funded by the National Science Foundation (NSF).

The foam consists of a nickel-manganese-gallium alloy whose structure resembles a piece of Swiss cheese with small voids of space between thin, curvy "struts" of material. The struts have a bamboo-like grain structure that can lengthen, or strain, up to 10 percent when a magnetic field is applied. Strain is the degree to which a material deforms under load. In this instance, the force came from a magnetic field rather a physical load. Force from magnetic fields can be exerted over long range, making them advantageous for many applications. The alloy material retains its new shape when the field is turned off, but the magnetically sensitive atomic structure returns to its original structure if the field is rotated 90 degrees--a phenomenon called "magnetic shape-memory."

Making large single crystals of the alloy material is too slow and expensive to be commercially viable -- one of the reasons why gems are so costly -- so the researchers make polycrystalline alloys, which contain many small crystals or grains. Traditional polycrystalline materials are not porous and exhibit near zero strains due to mechanical constraints at the boundaries between each grain. In contrast, a single crystal exhibits a large strain as there are no internal boundaries. By introducing voids into the polycrystalline alloy, the researchers have made a porous material that has less internal mechanical constraint and exhibits a reasonably large degree of strain.

The researchers created the new material by pouring molten alloy into a piece of porous sodium aluminate salt. Once the material cooled, they leached out the salt with acid, leaving behind large voids. The researchers then exposed the porous alloy to a rotating magnetic field. The level of strain achieved after each of the over 10 million rotations is consistent with the best currently used magnetic actuators, and Müllner and Dunand expect to significantly improve the strain when they have further optimized the foam's architecture.

"The base alloy material was previously known, but it wasn't very effective for shape-memory applications," Dunand said. "The porous nature of the material amplifies the shape-change effect, making it a good candidate for tiny motion control devices or biomedical pumps without moving parts."

NSF Program Director Harsh Deep Chopra agrees. "It's the first foam to exhibit magnetic shape memory - it has great potential for uses that require a large strain and light weight such as space applications and automobiles. These materials are able to do more with less material given their foamy structure and provide a sustainable approach to materials development."

The work was funded by NSF through grant DMR-0502551 to expand basic knowledge about the microstructural properties of shape memory alloys influenced by magnetic fields and through grant DMR-0505772 to develop new shape-memory foams.

####

About National Science Foundation

The National Science Foundation (NSF) is an independent federal agency that supports fundamental research and education across all fields of science and engineering, with an annual budget of $5.92 billion. NSF funds reach all 50 states through grants to over 1,700 universities and institutions. Each year, NSF receives about 42,000 competitive requests for funding, and makes over 10,000 new funding awards. The NSF also awards over $400 million in professional and service contracts yearly.

For more information, please click here

Contacts:

Media Contacts

Diane Banegas

National Science Foundation

(703) 292-4489

Program Contacts

Harsh Chopra

National Science Foundation

(703) 292-4543

Principal Investigators

David Dunand

Northwestern University

(847) 491-5370

Peter Mullner

Boise State University

(208) 426-5136

Copyright © National Science Foundation

If you have a comment, please Contact us.Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

![]() Peter Mullner biography and publications

Peter Mullner biography and publications

| Related News Press |

News and information

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||