Home > Press > New Hard Anodization Process for Nanoporous Aluminum Oxide

Abstract:

Scientists from the Max Planck Institute of Microstructure Physics have developed a novel high-speed anodization process for self-ordered anodic Al2O3 membranes.

New Hard Anodization Process for Nanoporous Aluminum Oxide

Posted on September 01, 2006|

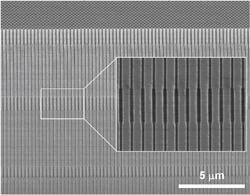

Abstract: Nanoporous anodic aluminium oxide has been widely used for the development of various functional nanostructures. So far these self-organized pore structures could only be prepared within narrow processing conditions. Here we report a new oxalic-acid-based anodization process for long-range ordered alumina membranes. This process is a new generation of the so-called 'hard anodization' approach that has been widely used in industry for high-speed fabrication of mechanically robust, very thick (>100 mum) and low-porosity alumina films since the 1960s. This hard anodization approach establishes a new self-ordering regime with interpore distances, (Dint)=200300 nm, which have not been achieved by mild anodization processes so far. It offers substantial advantages over conventional anodization processes in terms of processing time, allowing 2,500 - 3,500% faster oxide growth with improved ordering of the nanopores. Perfectly ordered alumina membranes with high aspect ratios (>1,000) of uniform nanopores with periodically modulated diameters have been realized. |

Aluminum anodization has been an indispensable process in industry. Anodization products can be found everywhere in our living: in our cooking utensils, window frames, electronic parts, etc. To date, the aluminum industry has mostly relied on a sulphuric acid based hard anodization process by taking advantage of the rapid growth of mechanically robust nanoporous oxide films. As a limitation of this industrial process the pores in the resulting oxide layers are quite disordered, and are not suitable for fabricating multifunctional nanostructured or high-technology products. Scientists at the Max Planck Institute of Microstructure Physics changed all this by developing a new oxalic acid based hard anodization process (Nature Materials 5, 741-747 (2006)). The new process offers several distinctive advantages that have not been achieved by conventional anodization processes. The findings will also provide a better understanding of the mechanism governing the self-ordering of oxide nanopores during the aluminum anodization.

When an aluminum substrate is electrochemically oxidized under constant potential, the surface of aluminum will be covered by a nanoporous oxide layer. This process has been known as anodization and has intensively been utilized for various industrial applications, including the formation of electrically insulating layers, anti-corrosion coatings, and decorative coloration of metal surfaces. The (aluminum or surface finishing) industry employs two types of anodization process for the formation of thick aluminum oxide (alumina) coatings: mild and hard. The latter, which is carried out at high voltage by using sulphuric acid, results in the rapid growth of thick porous oxide layer. These porous oxides film are normally even more disordered than those produced by mild anodization. This aspect is an important concern for the current nanotechnology research. However, so far in industry with fabrication facilities for bulk material this aspect has been completely ignored.

Woo Lee and co-workers from a BMBF Nanotechnology Research Group at Max Planck Institute of Microstructure Physics have developed a new oxalic acid based anodization process for long-range ordered alumina membranes. This process is a new generation of the so-called "hard anodization (HA)" process that has widely been employed in industry since the 1960s for various industrial applications (e.g., surface finishing of aluminum cooking ware, automotive engineering, machinery, medical implantation, etc.) for high-speed fabrication of mechanically robust, very thick and low-porosity anodic alumina. In academic research, however, the HA process has been out of focus in the past four decades and was not applied for the development of nanostructured materials so far due to difficulties in controlling important structural parameters, such as pore size, interpore distance, and the aspect ratio of nanopores of the resulting alumina membranes.

The researchers found that by pre-anodizing the aluminum surfaces, carefully controlling the surface heat evolution and appropriately selecting the anodizing voltage that a new self-ordering regime can be achieved that produces highly ordered porous templates that are thicker, produced 25-35 times faster and provide a new self-ordering regime with interpores distances in a previously unavailable size range. They proposed that the self-regulating cell formation under high current density (i.e., high electric field strength E) at the bottom of pores, that is also associated with the mechanical stress at the metal/oxide interface, is mainly responsible for the development of highly ordered pore structures during hard anodization. Based on their findings on the self-ordering behavior, the researchers realized perfectly ordered alumina membranes with ratios of pore depth to pore diameter larger than 1,000 of uniform nanopores with constant and periodically modulated diameters. These well-defined three-dimensional (3D) nanoarchitectures have the potential for a broad range of nanotechnology applications like 3D photonic crystals, meta-materials, microfluidics and for the template-based synthesis of multifunctional nanowires and nanotubes. Furthermore, the Max Planck scientists gain new insights into the mechanism of self-organization of nanopores during the anodization of aluminum (Nature Materials 5, 741-747 (2006).

Original work:

Woo Lee, Ran Ji, Ulrich Gösele, Kornelius Nielsch

Fast fabrication of long-range ordered porous alumina membranes by hard anodization

Nature Materials 5, 741-747 (2006)

www.nature.com/nmat/journal/v5/n9/abs/nmat1717.html

Contact:

Dr. Woo Lee

Max-Planck-Institut für Mikrostrukturphysik, Halle

Tel.: 0345 5582 929

Fax: 0345 5511 223

woolee@mpi-halle. de

Copyright © Max Planck Institute of Microstructure Physics

If you have a comment, please Contact us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related News Press |

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Materials/Metamaterials/Magnetoresistance

![]() First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

First real-time observation of two-dimensional melting process: Researchers at Mainz University unveil new insights into magnetic vortex structures August 8th, 2025

![]() Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

Researchers unveil a groundbreaking clay-based solution to capture carbon dioxide and combat climate change June 6th, 2025

![]() A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

A 1960s idea inspires NBI researchers to study hitherto inaccessible quantum states June 6th, 2025

![]() Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Institute for Nanoscience hosts annual proposal planning meeting May 16th, 2025

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||