Home > Press > Purdue Researchers Align Nanotubes To Improve Artificial Joints

Abstract:

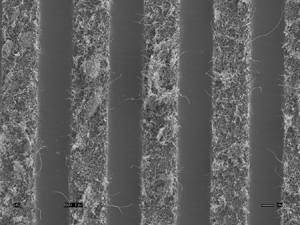

Osteoblasts Aligned with Carbon Nanotubes/Nanofibers

Purdue Researchers Align Nanotubes To Improve Artificial Joints

West Lafayette, IN – November 22, 2004

By Emil Venere

Researchers at Purdue University have shown that

artificial joints might be improved by making the implants out of tiny

carbon tubes and filaments that are all aligned in the same direction,

mimicking the alignment of collagen fibers and natural ceramic crystals

in real bones.

The researchers already have shown in a series of experiments that bone

cells in Petri dishes attach better to materials that possess smaller

surface bumps than are found on conventional materials used to make

artificial joints. The smaller features also stimulate the growth of

more new bone tissue, which is critical for the proper attachment of

artificial joints once they are implanted.

Now, the Purdue researchers have shown even more enhanced cell adhesion

and growth when so-called "nanotubes" and nanofibers are aligned in the

same direction. This orientation is similar to the way collagen and

natural ceramic crystals, called hydroxyapatite, are aligned in bone,

said Thomas Webster, an assistant professor of biomedical engineering

at Purdue.

Findings were presented at two recent scientific conferences in

research papers written by Webster; Purdue physics doctoral student

Dongwoo Khang; and three researchers from the Seoul National University

in South Korea, physics doctoral students Minbaek Lee and Sun Namkung,

and physics professor Seunghun Hong.

Previous experiments in the Purdue lab have shown that about one-third

more bone-forming cells, or osteoblasts, attach to carbon nanotubes

that possess surface bumps about as wide as 100 nanometers, or

billionths of a meter. Fewer bone cells stick to conventional titanium,

which has surface features on the scale of microns, or millionths of a

meter.

The nanometer-scale bumps mimic surface features of proteins and

natural tissues, prompting cells to stick better and promoting the

growth of new cells, Webster said. The findings also suggest that using

such nanometer-scale materials might cause less of a rejection response

from the body. Rejection eventually weakens the attachment of implants

and causes them to become loose and painful, requiring replacement

surgery.

Aligning the nanotubes to further mimic natural bone also might provide

more strength, Webster said.

Researchers used two methods to align the tiny nanotube structures,

which have diameters of about 60 nanometers. One nanometer is roughly

the length of 10 hydrogen atoms strung together. A human hair is more

than 1,000 times wider than the nanotubes used in the study.

In one method, researchers mixed the nanotubes in a polymer, or

plastic, and passed an electric current through the mixture. Because

nanotubes have the same natural electrical charge, they react to

electricity by orienting themselves in the same direction. Once the

polymer solidifies, the nanotubes are fixed in the aligned position.

The research team also aligned the nanotubes using another method in

which the nanotubes are poured into grids of tiny channels. Because the

channels are so narrow, the tubes can only fit lengthwise, causing them

to become aligned. The grids can then be removed, leaving behind the

aligned nanotubes.

The researchers then added the aligned nanotubes to a suspension of

dyed bone cells in a small container. After one hour, the nanotubes

were washed and a microscope was used to count how many of the dyed

osteoblasts adhered to the material. Out of 3,000 bone cells per square

centimeter of surface area, about 80 percent specifically stuck to and

aligned with the carbon nanotubes - or about twice as many as those

that adhered to non-aligned nanotubes in previous work.

"So, in a very short period of time, one hour, we're already seeing a

big improvement in how well the cells stick to the nanotubes," Webster

said.

Future research may focus on combining the two methods for aligning

nanotubes. Using the grid technique creates a greater number of aligned

nanotubes on the surface, which helps to increase bone-cell adhesion

and alignment, whereas using electricity could better stimulate the

growth of new bone tissue.

The research has been funded by the National Science Foundation though

the NSF Nanoscale Exploratory Research program.

Findings were presented in October during the Biomedical Engineering

Society's annual meeting and a conference by the Society for

Biomaterials entitled Biomaterials in Regenerative Medicine: The Advent

of Combination Products. Both meetings were in Philadelphia.

Writer:

Emil Venere

(765) 494-4709

venere@purdue.edu

Source:

Thomas Webster

(765) 496-7516

twebster@purdue.edu

Related Web sites:

Thomas Webster

Nano Letters

Note to Journalists: An electronic or hard copy of the research paper is available from Emil Venere, (765) 494-4709, venere@purdue.edu. A

publication-quality image of nanofibers aligned using grids of tiny channels is available here.

Contact:

Purdue University

News Service

400 Centennial Mall Drive, Rm. 324

West Lafayette, IN 47907-2016

(765) 494-2096

fax: (765) 49400401

purduenews@purdue.edu

Copyright © Purdue University

If you have a comment, please us.

Issuers of news releases, not 7th Wave, Inc. or Nanotechnology Now, are solely responsible for the accuracy of the content.

| Related Links |

| Related News Press |

Possible Futures

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Nanotubes/Buckyballs/Fullerenes/Nanorods/Nanostrings/Nanosheets

![]() Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

Tiny nanosheets, big leap: A new sensor detects ethanol at ultra-low levels January 30th, 2026

![]() Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

Enhancing power factor of p- and n-type single-walled carbon nanotubes April 25th, 2025

![]() Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

Chainmail-like material could be the future of armor: First 2D mechanically interlocked polymer exhibits exceptional flexibility and strength January 17th, 2025

![]() Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Innovative biomimetic superhydrophobic coating combines repair and buffering properties for superior anti-erosion December 13th, 2024

Discoveries

![]() From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

From sensors to smart systems: the rise of AI-driven photonic noses January 30th, 2026

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

Announcements

![]() Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

Decoding hydrogen‑bond network of electrolyte for cryogenic durable aqueous zinc‑ion batteries January 30th, 2026

![]() COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

COF scaffold membrane with gate‑lane nanostructure for efficient Li+/Mg2+ separation January 30th, 2026

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||