Home > Nanotechnology Columns > NanoNewsNet.ru > NT-MDT demonstrates a new approach to quartz crystal microbalance design and application

|

Eugene Birger Principal Analyst NanoNewsNet.ru |

Abstract:

Quartz crystal microbalance (QCM) measures a mass by detecting the change in resonance frequency of a quartz crystal resonator. The resonance is disturbed by the addition or removal of a small mass at the surface of the acoustic resonator. Frequency measurements are easily made to high precision; thus it is easy to measure mass densities down to a level of below 1 ng/cm2.

Let us elaborate on this brief description. The QCM is a simple, cost effective, high-resolution mass sensing technique based upon the piezoelectric effect. This technique provides a wide detection range: from small molecules or polymer films to much larger masses deposited on the surface. These can be complex arrays of biopolymers and bio macromolecules, even whole cells. In addition, QCM can provide information about the energy dissipating properties of the bound surface mass.

Another important and unique feature of the technique is the ability to measure mass and energy dissipation properties of films while simultaneously carrying out electrochemistry on solution samples. These measurements can describe the flow of electro polymerization of a film. They can also reveal the ions or solution transport within a film during changes in the film environment or state, including the oxidation reaction for an electro active film driven by the underlying surface potential. The past decade has witnessed an explosive growth in the application of QCM techniques to the study of a wide range of molecular systems at the solution-surface interface, in particular, biopolymer and biochemical systems.

March 31st, 2010

NT-MDT demonstrates a new approach to quartz crystal microbalance design and application

Piezoelectric effect in the quartz crystal: brief history

---------------------------------------------------------

In 1880 Pierre and Jacque Curie discovered that crystals of Rochelle salt (sodium potassium tartrate) could produce electricity when pressure was applied in certain crystallographic directions. They also showed the converse effect, i.e. production of strain by application of electricity. These findings resulted in discovery of the piezoelectric effect.

Later this effect was found also in the crystals of tourmaline, quartz, topaz, cane sugar, etc. The piezoelectric effect is reversible in that materials exhibiting the direct piezoelectric effect (the production of an electric potential when stress is applied) and also the reverse piezoelectric effect (the production of stress and/or strain when an electric field is applied). For example, lead zirconate titanate crystals show a maximum change of about 0.1% of the original dimension.

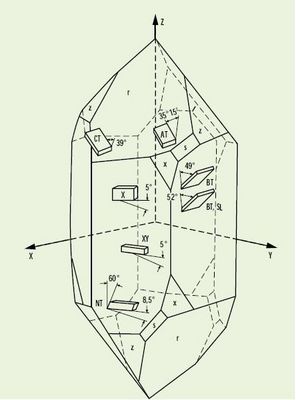

Piezoelectricity did not attract much interest in the beginning, and a more detailed study of piezoelectricity was not started until 1917 when it was demonstrated that quartz crystals could be used as transducers and receivers of ultrasound in water. In 1919 several devices of everyday use such as loudspeakers, microphones, and sound pick-ups based on the piezoelectricity of Rochelle salt were introduced to the public. In 1921 the first quartz crystal controlled oscillator was described. These oscillators were based on X-cut crystals. The disadvantage was their high temperature sensitivity. Therefore, the X-cut crystals are used nowadays in applications where the large temperature coefficient is of little importance, for instance in transducers of devices used in space.

|

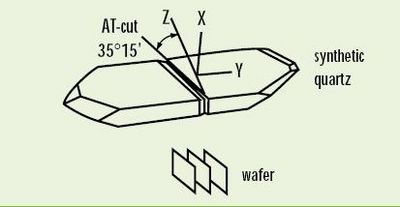

The dominance of quartz crystals for all kinds of frequency control applications started in 1934 when so-called AT-cut quartz crystal was introduced. The advantage of AT-cut quartz crystals is in its nearly zero frequency drift at room temperature range. In 1959 a German physicist G. Sauerbrey published a paper showing that the frequency shift of a quartz crystal resonator is directly proportional to the change of the mass. This work is considered to be a breakthrough and the first step towards a new quantitative tool to measure tiny masses- quartz crystal microbalance.

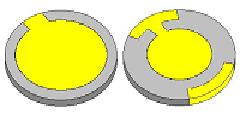

Thus QCM can be described as an ultra-sensitive mass sensor. Nowadays the major element of any QCM is a piezoelectric quartz crystal sandwiched between a pair of electrodes. When the electrodes are connected to an oscillator and AC voltage is applied to these electrodes the quartz crystal starts oscillating at its resonance frequency due to the piezoelectric effect. This oscillation is generally very stable as a result of high quality of the quartz crystal resonator.

Quartz crystals are an indispensable component of modern electronic technology. They are used to generate frequencies to control virtually all communication systems. They are used as isochronous elements in most digital clocks, computers, microprocessors, etc.

Why quartz?

-----------

The chemical formula of quartz is SiO2 and it is composed of two elements: silicon and oxygen. SiO2 is the major constituent of many rocks and sand. The crystalline form of SiO2 or quartz is relatively abundant in nature, but in the highly pure form required for quartz crystal units production its supply tends to be small.

The benefit that brings quartz to the top is its Q-factor (quality factor), which is calculated as the ratio frequency / bandwidth. The intrinsic Q-factor for quartz is very high and can reach 107. Such a sharp resonance makes oscillators extremely stable and provides high accuracy in frequency determination. Mounted resonators typically have Q-factors up to several hundred thousand times better than the best LC circuits. QCMs exploit their simplicity and precision for mass sensing.

The frequency of oscillation of quartz crystals is partially dependent on the thickness of the crystal. During regular operation all other affecting variables remain constant; thus a change in thickness correlates directly with a change in frequency. As particles of material deposit on the surface of the crystal, the thickness increases; consequently the frequency of oscillation decreases compared to initial value. With some assumptions this frequency change can be quantified and correlated precisely to the mass change.

|

The resonance frequency of acoustic resonators depends on temperature, pressure, and bending stress. Accurate control of temperature and stress is essential during the QCM operation. Temperature-frequency coupling is minimized by employing special crystal cuts; a broadly used temperature-compensated cut of quartz crystal is the AT-cut.

AT-cut crystals are singularly rotated Y-axis cuts in which the top and the bottom halves of the crystal move in opposite directions (thickness shear vibration) during oscillation. AT-cut crystals are relatively easy to manufacture. The cleanliness of the parts along with carefully designed and produced crystal cuts, as well as minimum stress on the resonator with inclusion of dry nitrogen atmosphere in a hermetically sealed package are of importance in manufacturing of stable and high quality quartz crystals. That is why most of times such operations as cutting the wafers, lapping and cleaning them, checking the orientation of wafers (X-ray measurements), rounding, cleaning and etching the wafers appear to be crucial.

|

However, there are certain limitations at high and low temperatures: the oscillations can be disrupted by internal stresses caused by temperature gradients. These internal stress points produce undesirable frequency shifts in the crystal decreasing the accuracy of measurements. The cubic dependence frequency/temperature has an inflection point (the point on the plot where the curvature determined by its second derivative changes it sign) around room temperature. As a consequence the AT-cut quartz crystal is most effective when operating at or close to room temperature. For operations at higher temperatures some water cooling can be successfully used.

Stress-compensated (SC) crystals are available with a double-rotated cut that minimizes the frequency changes due to temperature gradients when the system is operating at high temperatures and reduces the reliance on water cooling. SC-cut crystals have an inflection point of ~92 °C. In addition to their high temperature inflection point, they also have a smoother cubic dependency and are less affected by temperature deviations from the inflection point. However, due to more complicated manufacturing process they are expensive and not that popular commercially.

Applications of QCM

-------------------

Thus, QCM is basically a mass sensing device with the ability to measure extremely small mass changes on a quartz crystal resonator in real-time. The sensitivity of QCM is more than 100 times higher than an electronic fine balance. This means that QCMs are capable of measuring mass changes as small as a fraction of a monolayer or single layer of atoms. The high sensitivity and the real-time monitoring of mass changes on the sensor crystal make QCM a very attractive technique for a large range of applications.

QCM can be used in vacuum, gas phase ("gas sensor"), and more recently, liquid environments. It is useful for monitoring the rate of deposition in thin film deposition systems under vacuum. In liquid environment it is highly effective at determining the affinity of molecules (proteins in particular) to surfaces functionalized with recognition sites. Larger entities such as viruses or polymers are investigated as well. QCM has also been used to investigate interactions between biomolecules.

A brief list of the applications for QCM is shown below, and it looks like they are limited only by the reader's imagination:

-Immunosensors, antigen-antibody reactions

-Sorption sensors (particularly hydrogen absorption on metal films)

-Moisture analyzers, particulate monitors, and contamination monitors

-Electrovalence measurements

-Bubble formation (in numerous industries)

-Reduction-oxidation reactions and conductive polymer research

-Double-layer characterization

-Corrosion studies and surface oxidation

-DNA and RNA hybridization studies

-Protein adsorption, protein-protein interactions

-Detection of virus capsids (protein shell of a viruses), bacteria, mammalian cells

-Biofouling (undesirable accumulation of microorganisms, plants, algae, and/or animals on wetted structures) and antifouling

-Biomembranes and biomaterials, intelligent biomaterials

-Self-assembled monolayers (SAMs)

-Molecularly imprinted polymers (MIPs)

-Langmuir/Langmuir-Blodgett films (layers deposited from the surface of a liquid onto a solid surface)

-Laser ablation, desorption, and breakdown studies

-Nanomaterials for MEMS and NEMS.

Quartz Crystal Microbalance with dissipation (QCM-D)

-----------------------------------------------------

There has been an increasing demand for analytical tools that can quantify the interaction and/or reaction of nanoscale particles and polymers as well as biomolecules, with various surfaces. In-situ monitoring of structural and dynamic changes of these materials is of critical importance. With understanding of the behavior of these molecules at nanoscale, conditions for desired results can be optimized.

Frequency measurements are easily made to high precision; hence it is easy to measure mass densities down to a level of below 1 ng/cm2. In addition to measuring the frequency to help analysis, the dissipation is often measured. The dissipation is a parameter quantifying the damping (any effect that tends to reduce the amplitude of oscillations) in the system, and is related to the sample's viscoelastic (the property of materials that exhibit both viscous and elastic characteristics when undergoing deformation) properties. In physics, dissipation embodies the concept of a dynamic system where important mechanical modes, such as waves or oscillations, lose energy over time, typically due to the action of friction or turbulence. The lost energy is converted into heat, raising the temperature of the system.

Modern Quartz Crystal Microbalance with Dissipation Monitoring (QCM-D), a nanomechanical acoustic-based analytical technique, provides in situ, real-time characterization of the interactions of various polymeric and biomaterials at variety of interfaces. With QCM-D simultaneous measurement of resonance frequency change and energy dissipation change is performed by periodically switching off the driving power of oscillation of the sensor crystal and recording the decay of damped oscillation as the adsorption and/or structural changes take place at sensor crystal surface. While the changes in frequency provide information about the changes in mass, the changes in dissipation provide structural information about the viscoelastic properties of adsorbed films in real time.

As we mentioned earlier the heart of a QCM instrument is a thin (0.2-0.5 mm) AT-cut quartz crystal with an electrode on each side. When biased with alternating current, transversal (shear) waves with anti-nodes at the two surfaces will be generated in the crystal due to the piezoelectric nature of quartz. The crystal is driven at its resonance frequency to obtain maximum amplitude.

The oscillating quartz crystal system while coupled to the surrounding medium, creates exponentially decaying shear waves. This in turn changes the resonance frequency of the quartz crystal, with an amount that is proportional to the mass of the adsorbed layer. Thus continually measuring the resonance frequency is equivalent to continuously measuring the adsorbed mass. By abruptly turning off the alternating current the oscillations of the crystal will decay exponentially as energy dissipates through internal friction in the adsorbate. The measured decay time depends on the viscoelastic properties of the adsorbed layer.

Revolutionary new step in design: NT-MDT's Quartz Crystal Microbalance with

---------------------------------------------------------------------------

Dissipation monitoring combined with AFM

----------------------------------------

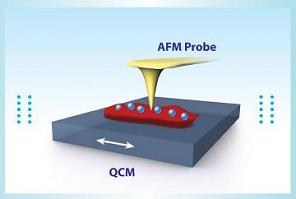

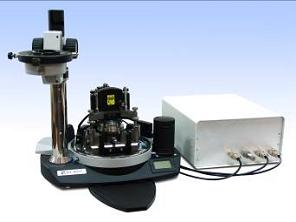

NT-MDT Company launched in production a new and unique device. Its specific design incorporates the quartz microbalance into hermetic cell of the atomic force microscope (AFM). This integrated system made on the basis of AFM and QCM is capable to carry out simultaneous monitoring of the surface structure changes and corresponding changes in the integral adsorbed mass at different phases of gas sensor operation environments. In other words, an operator is able to "weight" these molecules and simultaneously "watch" them using a single device! What affects the mass changes? What happens with the surface morphology on the nano level? All these and many other problems can be investigated in solutions with composition and properties that now can be changed and controlled in real time. The new QCM-D was designed and implemented by NT-MDT as an extremely sensitive instrument for label-free in situ structural properties and mass real-time measurements with subnanogram precision.

As an example of the integrated AFM and QCM device operation it is useful to describe a model experiment provided by Russian researchers using NT-MDT equipment. Nanocrystals of hafnium oxide are used as a matrix for sensing elements in gas nanosensors due to their high gas sorption ability magnified by their branched structure. The experiment shows the possible gas sensor operational principle on the basis of Quartz Crystal Balance and Atomic Force Microscope combination.

The sample was prepared in two following steps: Hafnium oxide nanocrystals were dispersed in aqueous-alcohol solution of bromocresol purple (BCP, well known pH indicator) and deposited on a gold surface; the agglomerate formation contented 20-80 nm clusters of nanocrystals.

The instrument included a device for ammonia vaporization, an ammonia gas analyzer, a gas flow-through cell, a QCM (with a crystal resonator, a built-in gas cell, and an electric circuit vector analyzer- control unit), and an AFM with probe, placed next to the crystal resonator of QCM.

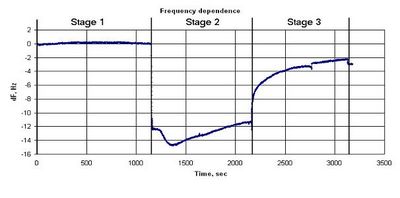

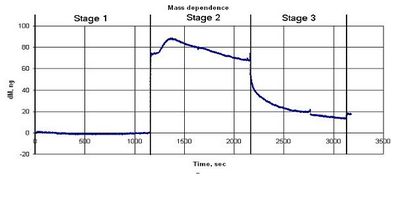

The quartz crystal resonator with the sensor materials coating was introduced to the gas flow via the cell. The ammonia and nitrate mixture had been injected to the cell. The hafnium oxide nanocrystals absorb the ammonia. That is confirmed by the nanocrystals mass increasing (see the graphs below). For the system to return to initial condition (after the ammonia stopping) it was blown through by pure nitrogen. The desorption occurred at this phase is confirmed by nanocrystals mass decreasing and corresponding quartz resonator oscillation frequency increasing. The plots below represent oscillation frequency and mass changes vs time. The mass was calculated according to the Sauerbrey model.

The AFM images clearly show the selected hafnium oxide cluster relief changes under the gas influence. You can see the description of the experiment and results in full

The experiment presented the capabilities of the combined system based on AFM and QCM. The AFM and QCM integration provides simultaneous monitoring of the surface structure changes and corresponding changes of the integral adsorbed mass at various phases of the gas sensor operation.

|

|

This new equipment set continues the NT-MDT line of equipment development tradition towards the flexible integration of various research approaches with the techniques of scanning force microscopy, which substantially broadens the spectrum of options for nanosize objects study. At the same time the unique dual-use device QCM-D is able to operate as an independent tool, and yet it could be easily integrated with AFM by NT-MDT Company.

|

QCM-D by NT-MDT: operational principles

---------------------------------------

Here are the major operational properties of the NT-MDT's QCM-D. Generally speaking, they follow the mechanical principles of the technique we discussed earlier. Lateral oscillations of the quartz crystal are excited by alternate voltage applied to the electrodes. The basic harmonic oscillation frequency is 5 MHz. The mass changes measured correspond to the resonance frequency variations. Viscoelastic properties changes conform to changes of Q-factor. Using precise multiple overtones measurements of the quartz crystal resonator and Q-factor measurements the QCM-D provides the detailed and accurate information about the mass, thickness and viscoelastic properties of the sample. As a result, this integrated instrument is able to perform real time in situ observation of object morphology (with nm precision) and simultaneous mass change measures (with accuracy up to 0.3 ng).

|

|

Combining AFM and QCM-D: advantages

-----------------------------------

Thanks to the new NT-MDT pioneering instrument the range of possible functions of QCM-D is substantially enlarged due to whole arsenal of AFM techniques. Modular design of the QCM-D provides quite a simple integration with the NTEGRA or SOLVER instrument platforms.

Thanks to QCM-D compatibility and integration with the AFM a user by combining various instruments is able to assemble a system that meets cutting edge requirements for the following applications:

- Research in viscoelastic properties of thin films (for example, polymer films)

- Study of tribological interactions

- Analysis of sensor materials

- R&D related to Scanning Acoustic Microscopes

- Research in self-assembly layers and molecules, etc.

For more information about these new techniques, instruments and their advanced applications visit this [link : http://www.ntmdt.com/news/view/novaya-razrabotka-unikalnoe-sochetanie-kvarcevyh-mikrovesov-i-asm : NT-MDT website]

References

1. W.H. King, Jr. (1964). "Piezoelectric sorption detector". Analytical Chemistry 36 (9): 1735--1739. doi:10.1021/ac60215a012

2. "Linear Piezoelectric Plate Vibrations" by H. F. Tiersten. (Plenum, New York, 1969). Mathematics of piezoelectricity in detail. A valuable resource for theoretical work on QCM.

3. "IEEE Standard on Piezoelectricity", copyright 1978 by the Institute of Electrical and Electronics Engineers, Inc. ANSI/IEEE Std 176-1978. IEEE Transactions on Sonics and Ultrasonics, SU-31, No. 2, Part II, March 1984. 55 pages.

4. "Introduction to Quartz Crystal Design" by Virgil E. Bottom. (van Nostrand Reinhold, New York, 1986). Discussed quartz and numerous piezoelectric devices in detail. Gives information important to experimentalists.

5. G. Sauerbrey. "Verwendung von Schwingquarzen zur Wägung dünner Schichten und zur Mikrowägung". Z. Phys. 155: 206 (1959). doi:10.1007/BF01337937) . The original paper proposing QCM.

6. C. Lu and D. Lewis. J. Appl. Phys., 43 4383 (1972). This paper was the first to reduce the results to a simple transcendental formula.

7. C. E. Reed, K. K. Kanazawa and J. H. Kaufman. J. Appl. Phys., 68 1993 (1990). Discussed QCM from a physical point of view including piezoelectric coupling.

8. Z. Lin and M. D. Ward, Analytical Chem., 67 685 (1995). This paper provides experimental evidence that a QCM operating in a liquid can emit sound waves into the liquid, producing extra losses.

|

|

||

|

|

||

| The latest news from around the world, FREE | ||

|

|

||

|

|

||

| Premium Products | ||

|

|

||

|

Only the news you want to read!

Learn More |

||

|

|

||

|

Full-service, expert consulting

Learn More |

||

|

|

||